High Flowrate Split Casing Centrifugal Water Pump for Irrigation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High Flowrate Split Casing Centrifugal Water Pump for Irrigation

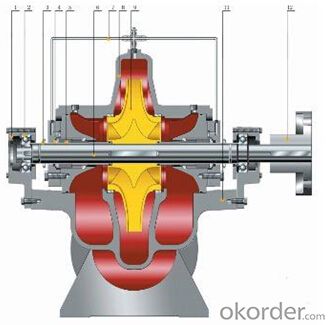

1.Structure of High Flowrate Split Casing Centrifugal Water Pump for Irrigation Description

The Single Stage Double Suction Water Pump is designed for pump station, The casting is axially split, which permits removal of the complete rotor whish moving either piping or motor. Pumps generating high heads have double volute to reduce radial forces. Replaceable wear ring protect the casting at the impeller running clearances. Flange drilled to ISO, DIN, BS or ANSI. The close double suction impeller gives practically zero axial forces. Each impeller is statically and dynamically balanced according to ISO 1940.The pumps have a reduced number of parts and extensive interchangeability, which leads to minimum levels of inventory for customers and faster parts delivery. Vertical installation is a standard option with the same upper and lower casing parts. It is mounted for a space-saving configuration or when apace is at a premium. Soft packing or mechanical seal, grease or oil lubricated bearing is optional. Oil lubrication is with constant level oiler.

2.Main Features of the High Flowrate Split Casing Centrifugal Water Pump for Irrigation

• Compact structure

• Attractive design

• High efficiency, steady performance

• big capacity, medium pressure

• High concentricity of components

3. High Flowrate Split Casing Centrifugal Water Pump for Irrigation Images

4. High Flowrate Split Casing Centrifugal Water Pump for Irrigation Specification

Casing | Cast Iron, Ductile Cast Iron, Cast Steel, Stainless Steel or Duplex S.S |

Impeller | Cast Iron, Bronze, Duplex S.S, Stainless Steel |

Shaft | C-Steel, Cr-Steel, Stainless Steel |

Wearing Ring | Cast Iron, Brass, Stainless Steel |

Capacity/Q | Up to 25000m3/h, Up to 110000gpm |

Head/H | Up to 280m, Up to 800 feet |

Temperature/T | Up to 200degree |

Speed/n | 2900/1450/980/740/580 rpm 3500/1750/1180/890/710rpm |

5.FAQ

①What is the applications?

Besides irrigation and drainage pumping Station, the Single Stage Double Suction Split Casing Centrifugal Pump also can be used for Circulation water for air-condition, water supply for industry and building, and other waterworks.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance. Normally, We have 1 year warranty.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. It related to the state and detailed requirement of customers.

- Q: What is a water pump coupling device?

- Advantages of water pump coupling device:1. automatic coupling device, easy installation and maintenance. In the absence of automatic coupling device, fixed installation, such as water pump failure, maintenance personnel need to unscrew screws, lifting pumps for maintenance, or with other small pumps pumping water perfect maintenance,If the water is dirty, it is difficult for people to get down, when the inspection and repair encountered great difficulties. But it is equipped with GAK submersible sewage pumpAfter the automatic coupling device needs lifting, the person can directly lift the water pump without the need to screw the screw into the waterAfter graduation, down the guide rail, you can realize the sealing of water pump and pipeline, so as to make the pump run normally. Small sewage pumps are freeInstallation, large sewage pumps are generally equipped with automatic coupling device, automatic installation, installation and maintenance is very convenient.

- Q: The function of centrifugal pump

- 2, pump body, also known as pump shell, it is the main body of the pump. The utility model is provided with a supporting and fixing function and is connected with a bracket for mounting the bearing.3, the role of the pump shaft is to use the coupling and motor connected, the motor transfer distance to the impeller, so it is the transfer of mechanical energy of the main components.

- Q: What is the pump delivery? What's the difference between years and years?

- Secondly, the landlord asked the question, although I did not go to the insurance company to practice the operation, but to my four years of learning, as well as internship experience, or can help you analyze, and I hope to help you.Pay is a one-time payment of premium -- all wholesale D sea n

- Q: What are the main performance parameters of hydraulic pumps?

- Main performance parameters of hydraulic pump:1. Hydraulic pump pressureHydraulic pump operating pressure is the pump (or motor) in actual work output (or input) oil pressure, determined by the external load.Rated pressure refers to the maximum pressure under continuous running in accordance with the test standards under normal working conditions. The size of the pump is limited by the service life, and the service life of the pump (or motor) will be shorter than the design life if it exceeds the rated pressure. When the work pressure is greater than the rated pressure, it is called overload.

- Q: What is the pumping property of concrete?

- Pumpable concrete slump is generally greater than 160mm, the mortar content is too low, the maximum aggregate size of not more than 1/3 of the diameter of the pump pipe, sending process segregation, plugging in the pump.

- Q: What are the constant pressure pumps?

- Constant pressure pump is also called the booster pump, the name is used for booster pump, its main purpose is water heater booster, with tall low pressure, sauna, bath and other pressure in the apartment, the lack of water pressure, solar automatic pressurization and so on.

- Q: Hydraulic pump displacement refers to the pump shaft what?

- Just as you carry a spoon to the water. How much water can you pump at once (every turn)? That's the displacement.

- Q: How to maintain and repair the booster pump of pipeline pump?

- I. installationAssembly and disassembly1. scrub all the spare parts to be cleaned.2. mechanical seals are installed on the main shaft of the motor, and a small amount of clean turbine oil or 20 oil is added to the surface of the mechanical seal.

- Q: Attention should be paid to the use of pumps?

- 7 water pump and pipe interface must be sealed, because if there is debris access, then the pump will cause damage to the interior. 8 for the water pump bearing is also the focus of inspection, use up to check whether the bearings wear,

- Q: What's the submersible pump?What is a submersible pump, and what about it?

- Deep well submersible pump is a fountain, drinking water transportation, irrigation, hot springs, high-rise transport facilities, etc., deep well submersible pump excellent performance, so widely used in various fields.

Send your message to us

High Flowrate Split Casing Centrifugal Water Pump for Irrigation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches