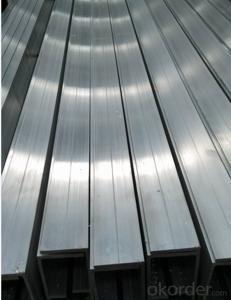

High-end Architectural Aluminium Formwork System

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 150000 /month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Why choose us?

1. Easy transaction & pleasure cooperation are our tenets all the time.

2. Every detail will be emerged in your brain clearly.

3. Don't worry about anything, we will figure it out for you with our professional technology & excellent service.

4. We aim at satisfy your demands.

5. Never the best but the most suitable plan to you, for it we are willing to put every effort determinedly.

Aluminum Formwork System Advantages

Economic traits

Frequent recycling and low averaging cost;High recovery rate and residual value;High efficiency of construction,short construction period;No crane,less labor cost(70% of timber and steel formwork)

High Quality

Good construction effects & quality; No troweling;Wide scope of application and strong bearing capacity;High stiffness and light weight

Environmenta Protection

Safe construction and no construction waste;Ecological and clean production;Popularization and promotion;Benefit the society

Design

International Design Team;Advanced Design Platform;Open-minded Design Concept

Service

Professional Installation Group;Committed Service,Source of Development;Stay close to the customers and provide speedy services 。

- Q: What are the maintenance and maintenance of hydraulic climbing formwork

- After the shift between the device and the main girder is inserted on the pin and the pin card, after the shift is already used for rear jacking jacking, wind cable is tightened, the adjacent frame between the climbing frame is firmly rachel.

- Q: Climbing frame is divided into several kinds, what is its running mode? What is the rental cost? Please explain in detail! Thank you very much

- Climbing frame installation processInstallation of platform --- display base, installation guide, assembling components - horizontal truss beam with the bolt on the guide rail, the main frame vertical rod buckle on the beam - diagonal rod buckle on the vertical rod and beam - wall installation guide device, the frame structure of unloading with elevated body, the erection of scaffolding, the laying of the intermediate layer or temporary scaffolding and temporary building structure frame of pulling and hanging outside the dense mesh safety net - loaded third beams to guide seat -

- Q: The difference between the scaffold and the scaffold

- Climbing frame, also known as the lifting frame, according to its source of power can be divided into hydraulic, electric, manual pull and other major categories. It is a new type of scaffolding system developed in recent years, which is mainly used in high-rise shear wall construction. It can climb up or down the building. This system makes the change: one is the scaffold without turning over shelf, two is exempt from the disassembly process of scaffold (an assembly has been used after the completion of construction, and not affected) building height restrictions, greatly saves manpower and material. And in terms of security is also a big change for the traditional scaffolding. Highly developed in high-rise buildings.

- Q: Advantages and disadvantages of climbing frame and floor type scaffold

- 2) easy to install and disassemble, set up flexible. Because the length of the steel tube is easy to adjust and the fastener is convenient to connect, the utility model can be used for various buildings and structures with various planes and elevations.

- Q: The whole concrete wall climbing frame or good use of steel scaffolding

- It can climb up or down the building. This system makes the change scaffolding Technology: one is without turning over the shelf; two is exempt from the disassembly process of scaffold (an assembly has been used after the completion of construction, and not affected) building height restrictions, greatly saves manpower and material

- Q: What is an integrated climbing frame? What are the works? What are the advantages

- And in terms of security is also a big change for the traditional scaffolding. Highly developed in high-rise buildings. Rental fees do not want the same

Send your message to us

High-end Architectural Aluminium Formwork System

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 150000 /month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords