Premium Construction Stacking Tower Scaffolding

- Loading Port:

- XINGANG

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 Set/Sets set

- Supply Capability:

- 100 Ton/Tons per Day set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Quick Details of Premium Construction Stacking Tower Scaffolding:

Place of Origin: China (Mainland)

Brand Name: CMAX

Model Number: HF Tower Scaffolding

Type: Tower Scaffolding

Material: Q235 steel

pipe Color: Orange, dark red, blue or as you required

Surface Finished: Dip painted

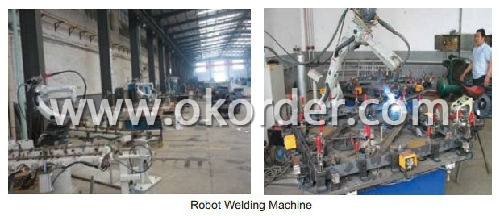

Technique: CO2 arc welding

Working Height: 1.524-1.93m/set

Thickness: 2.0/2.2mm

Diameter: 42mm

Application: Tower Scaffolding for internal and external construction

Certification: SGS

2. Packaging & Delivery of Premium Construction Stacking Tower Scaffolding:

Packaging Detail:

1.Tower Scaffolding is in bare package, loading in container.

2.Loading plan: for HF 1930: 200 sets per 20 GP; 550 sets per 40 HQ. For HF 1700: 250 sets per 20 GP; 600 sets per 40 HQ.

Delivery Detail: 15 days after the deposit

3. Specifications of Premium Construction Stacking Tower Scaffolding:

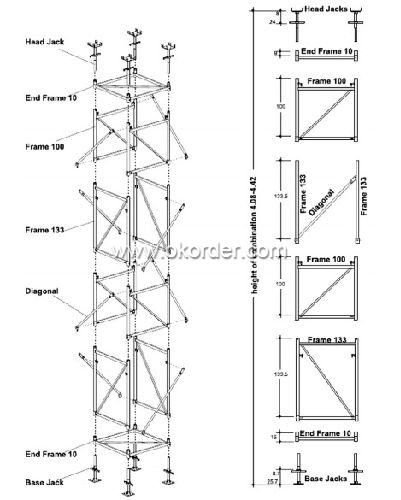

Tower Scaffolding

1.Material: Q235 steel pipe

2.Surface treatment: dip painted

3.Light weight; competitive price

Shoring tower is an effective supporting system.It is easy to assemble and dismantlement, and has excellent stability and bearing capacity.It has been widely used in the construction of industry & residential buildings,bridges,tunnels and dam project,etc.

4. CHARACTERISTICS of Premium Construction Stacking Tower Scaffolding:

High degree of standardization

Easy storage and transportation

Typical standard components:

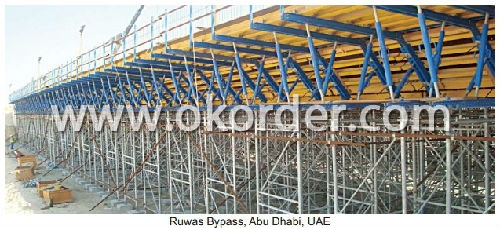

5. PROJECT APPLICATION

- Q: What are the maintenance and maintenance of hydraulic climbing formwork

- Regular inspection of the climbing device should check the connections. In particular, the following parts of the site to focus on inspection and reinforcement: according to the design requirements of the bolt with spring washers

- Q: Climbing frame is divided into several kinds, what is its running mode? What is the rental cost? Please explain in detail! Thank you very much

- Climbing frame installation processInstallation of platform --- display base, installation guide, assembling components - horizontal truss beam with the bolt on the guide rail, the main frame vertical rod buckle on the beam - diagonal rod buckle on the vertical rod and beam - wall installation guide device, the frame structure of unloading with elevated body, the erection of scaffolding, the laying of the intermediate layer or temporary scaffolding and temporary building structure frame of pulling and hanging outside the dense mesh safety net - loaded third beams to guide seat -

- Q: The difference between the scaffold and the scaffold

- The difference between climbing frame and scaffolding is commonly used scaffolding from below has been set up, which is followed by building up climbing frame, the figure is upstairs, they have in common is that we are like scaffolding

- Q: Advantages and disadvantages of climbing frame and floor type scaffold

- Floor scaffold:Advantage:1) large bearing capacity. When the scaffolding geometry and structure comply with the relevant requirements, under normal circumstances, the bearing capacity of 15kN ~ 35kN of the single column scaffold (1.5tf ~ 3.5tf, design value).

- Q: The whole concrete wall climbing frame or good use of steel scaffolding

- It can climb up or down the building. This system makes the change scaffolding Technology: one is without turning over the shelf; two is exempt from the disassembly process of scaffold (an assembly has been used after the completion of construction, and not affected) building height restrictions, greatly saves manpower and material

- Q: What is an integrated climbing frame? What are the works? What are the advantages

- The climbing frame, which is also called the lifting frame, can be divided into several types, such as hydraulic, electric, manual and so on. It is a new type of scaffolding system developed in recent years, which is mainly used in high-rise shear wall construction.

Send your message to us

Premium Construction Stacking Tower Scaffolding

- Loading Port:

- XINGANG

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 Set/Sets set

- Supply Capability:

- 100 Ton/Tons per Day set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords