H14 H16 H18 5052 Flat Aluminum Roofing Sheets for Decoration

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

H14 H16 H18 5052 aluminum plate for decoration

ALLOY : AA1***(AA1050,AA1060,AA1070,AA1100etc)

AA3***(AA3003,AA3004,AA3005,AA3105etc)

AA5***(AA5052 etc)

TEMPER:H14,H18,H24,H26,H32

THICKNESS:0.2mm-20mm

WIDTH:10mm-1500mm

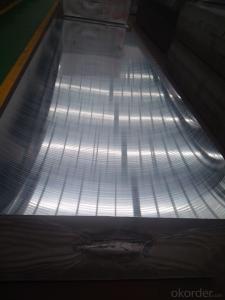

EMBOSSED PATTERNS : Diamond, stucoo,bars etc

STANDARD: GB/T3880-2006

Special specification is available on customer's requirement

Product Description

Goods name | Aluminum plate |

alloy | Yes |

Plance of origin | China |

Quality | Prime quality |

Certificate | ISO9001 |

Grade | 3000 Series |

Thickness | 0.3-150mm |

Type | Plate |

Width | 300-1950mm |

Model number | 3003,3004,3005,3014,3105 |

Surface | Mill finish |

Temper | O-H112 |

Ensure | we can supply customers' with different specifications of the highest quality and lowest price. Sincerely welcome to contact us for the future details if any item interest you ,and we will make every effort to assure that your requirements will be satisfied,and we hope to establish long-term business relations with you on the basis of the equality and mutual benefit. |

- Q: Could copper wire be welded with aluminum sheet?

- Copper wire could be welded with aluminum sheet, and it needs to use low temperature welding method, if copper wire is in the unit of millimeter and aluminum sheet is also in the unit below 1 mm, you can use electric soldering iron to heat it as hybrid welding and choose low temperature welding materials, you can use WEWELDING M51 welding wire and M51-F flux to complete welding. As for the large aluminum sheet, you can take liquefied gas multihole lance as heat source, then choose the same low temperature materials as welding materials, you can use WEWELDING M51 welding wire and M51-F flux to complete welding. Welding fundamentals of these two welding methods: both of them are use heatable heat source to heat the matrix to 179 degree, the melting point of WEWELDING M51, then use matrix’s heat conduction to melt welding wire, completing welding. The process of melting welding wire is the process of smearing the welding wire with flux into welding area, melting welding wire completely depends on matrix’s heat conduction.

- Q: Can aluminum sheets be hydroformed?

- Yes, aluminum sheets can be hydroformed.

- Q: Are aluminum sheets conductive?

- Yes, aluminum sheets are conductive. Aluminum is a metal and has a high electrical conductivity. This means that electricity can easily flow through aluminum sheets, allowing them to be used in various applications where conductivity is required, such as in electrical wiring, power transmission lines, and electronic devices.

- Q: Can aluminum sheet be used for heat sinks?

- Yes, aluminum sheet can be used for heat sinks. Aluminum is a common material used for heat sinks due to its excellent thermal conductivity properties. It is lightweight, affordable, and has good corrosion resistance. Aluminum sheet can be easily fabricated into various shapes and sizes, making it suitable for different heat sink designs. The flat and thin nature of aluminum sheet allows for efficient heat dissipation by increasing the surface area available for heat transfer. Additionally, aluminum can be easily machined or extruded to create fins, which further enhance the heat dissipation capability of the heat sink. Overall, aluminum sheet is a popular choice for heat sinks in various applications, including electronics, computers, LED lights, and automotive components.

- Q: If something is wrong, what kind of glue can be used for bonding the stainless steel sheet and aluminum sheet? The area may be very big. What are some common or good glue to buy?

- Is the whole surface covered with glue or covered with four sides?What are you asking for?This kind of structure can use more glue,Acrylic structural adhesive, epoxy structural adhesive, silicone structural adhesiveNeed to understand glue, we can communicate,

- Q: I've had a Champion bass boat forever, but today I bought an aluminum G3 boat that was so cheap I couldn't pass it up. The G3 is aluminum. What are the pros and cons?

- This Site Might Help You. RE: What are the advantages/disadvantages of aluminum vs fiberglass bass boat? I've had a Champion bass boat forever, but today I bought an aluminum G3 boat that was so cheap I couldn't pass it up. The G3 is aluminum. What are the pros and cons?

- Q: What is the tensile strength of 101 aluminum sheets?

- The tensile strength of 101 aluminum sheets varies depending on the thickness and manufacturing process, but it typically ranges from 20,000 to 30,000 pounds per square inch (PSI).

- Q: What are the different heat treatment options available for aluminum sheets?

- There are several heat treatment options available for aluminum sheets, each offering different properties and characteristics to the material. 1. Annealing: This process involves heating the aluminum sheet to a specific temperature and then slowly cooling it down. Annealing helps to relieve internal stresses in the material and improve its ductility and machinability. 2. Solution Heat Treatment: This treatment involves heating the aluminum sheet to a high temperature and then rapidly quenching it in water or other cooling media. Solution heat treatment is commonly used to dissolve and homogenize any alloying elements present in the aluminum, resulting in improved strength and hardness. 3. Precipitation Hardening: Also known as age hardening, this treatment is typically performed after solution heat treatment. It involves heating the aluminum sheet at a lower temperature for a specific period, allowing the alloying elements to precipitate and form fine particles. This process increases the strength and hardness of the aluminum without sacrificing its ductility. 4. Stress Relieving: This treatment is performed to relieve residual stresses that may have developed during fabrication or machining processes. The aluminum sheet is heated to a specific temperature and then slowly cooled down, reducing the risk of distortion or cracking. 5. Hardening: By heating the aluminum sheet to a specific temperature and then rapidly quenching it, hardening can be achieved. This process increases the strength and hardness of the material, making it more suitable for applications that require high strength-to-weight ratios. It is important to note that the specific heat treatment option chosen for aluminum sheets depends on the desired properties and application requirements. Consulting with a metallurgical expert or referring to the material's specifications can help determine the most suitable heat treatment option.

- Q: Are aluminum sheets suitable for thermal insulation?

- Aluminum sheets, by themselves, are not suitable for thermal insulation. Despite aluminum's ability to conduct heat and electricity well, it lacks sufficient insulating properties. Surprisingly, instead of blocking heat, aluminum sheets can actually transfer it, rendering them ineffective for thermal insulation purposes. To achieve proper thermal insulation, it is common to use materials with low thermal conductivity, such as fiberglass, mineral wool, or foam boards. These materials are specifically engineered to trap air or establish a barrier that minimizes heat transfer, thus ensuring efficient insulation.

- Q: Can the aluminum sheets be used for manufacturing chemical reaction vessels?

- Yes, aluminum sheets can be used for manufacturing chemical reaction vessels.

Send your message to us

H14 H16 H18 5052 Flat Aluminum Roofing Sheets for Decoration

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords