Sheets of Metal Aluminum Ut 5052 Aluminum Sheet for Exterior Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Common Aluminum Sheet Coil

1. Place of Origin: ZheJiang, China (Mainland)

2. Model Number: 1050/1060/3003/3004/5052/8011

3. Thickness: 0.20-20.0 mm

4. Width: 1000-1700 mm

Packaging & Delivery

1. Coating: Wooden Pallet for Exporting

2. Delivery Detail: 25-30 Days

Specifications

Aluminum Sheet

1. Alloy: 3003A1050/1060/3003/3004/5052/8011

3. Thickness (mm): 0.20-20.0

4. Width (mm): 1000 mm to 170 0mm, Customer Specific Width

5. Finish: Mill, Customer Specific Finish

Our main products are aluminum alloy thick sheet

PS/CTP plate (1050)

anodic oxidation / 3003/5052 (1060/1070)

automotive aluminum alloy (5754/6111/6061)

soldering material (3003/4004)

IT used materials (3003/5052)

the LED base material, material can (3004/3104)

the tank cover and TAB (5052/5182)

aluminous model with substrate (1100)

medicinal foil (8011)

household foil aluminum foil (1235) (8011)

Service

1. We have the good and professional team, have a good after-sales service.

2. Accept any drawings or your samples to develop new product.

3. Offer relateive technical support,quick response,all your inquire will replied within 24 hours.

4. OEM, buyer design, buyer label services provided.

5. Have the certification of ISO 9001, SGS.

6. Special discount and protection of sales area provided to our distributor.

FAQ

Q1:Do you provide sample? How many days will samples be finished?

Free samples will be provided if needed, but customers should undertake shipping cost or freight charges, samples will be finished in 5-7days

Q2: Can we visit your factory?

Welcome to our factory at any time.

Q3: Complaint solving process

Finding your salesman—Salesman provide you the solution (If it’s our responsibility, we will resend substitutes or return money or provide discount for your next order, etc.; If it’s shipping company’s responsibility, we will also help you until the problem is resolved.) —If salesman can’t solve your problem, please call our manager .

Q4: Delivery time

3~30working days after confirming the payment. If the order is urgent, we will push our workers to finish in advance.

Q5: What's your MOQ?

Normally 8MT are requested as the minium order quantity ,we shall give

additional instructions in special circumstances.

Q6: What are the terms of payment and currencies do you accept?

T/T or L/C is accepted, currently we appreciated your payment through

USD,EUR, RMB

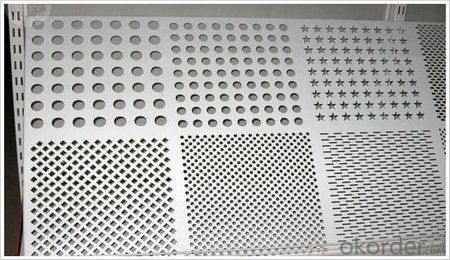

- Q: What are the different methods of surface patterning aluminum sheets?

- There are several methods available for surface patterning aluminum sheets, each with its own advantages and applications. Some of the commonly used methods include: 1. Mechanical Etching: This method involves the use of abrasive materials, such as sandpaper or wire brushes, to create patterns on the surface of the aluminum sheet. By applying varying pressure and movement, desired patterns can be achieved. Mechanical etching is a cost-effective and versatile method, suitable for creating simple to complex patterns. 2. Chemical Etching: Also known as chemical milling, this method uses chemicals to selectively remove material from the aluminum surface, creating patterns. The aluminum sheet is coated with a resist and then immersed in an etchant solution that dissolves the exposed areas, leaving behind the desired pattern. Chemical etching allows for precise and intricate designs but requires careful control of the etching process. 3. Laser Engraving: This method utilizes a high-power laser beam to remove material from the aluminum surface and create patterns. The laser beam is controlled by computer software, allowing for precise and detailed designs. Laser engraving is suitable for both small and large-scale production and offers high accuracy and repeatability. 4. Embossing: In this method, the aluminum sheet is pressed between two dies that have raised patterns, creating a three-dimensional design on the surface. Embossing can be done through mechanical or hydraulic presses and is commonly used to add texture and aesthetic appeal to aluminum sheets, such as for decorative purposes or branding. 5. Printing: Various printing techniques can be used to apply patterns onto aluminum sheets. These include screen printing, where ink is forced through a mesh screen onto the aluminum surface, and digital printing, which uses inkjet technology for high-resolution patterns. Printing methods allow for a wide range of colors and designs, making them suitable for decorative applications. The choice of surface patterning method depends on factors such as the desired pattern complexity, production volume, cost considerations, and the intended end-use of the aluminum sheets. Each method offers unique advantages and limitations, and manufacturers can select the most appropriate technique based on their specific requirements.

- Q: i went on the apple education site cuz i was gonna order an aluminum today, and it isnt there anymore!!!! i was on it like 2 hours ago and it was...wtf!!! anyone know whuts up?

- Yes...All Aluminium Macbooks are now turned to Macbook Pros. So might want to try the Mid 2009 white macbook or you have to go with 13 Macbook Pro... vist www.parithi for details..

- Q: I have heard that consuming aluminum can increase your risk for Alzheimer's later in life.Knowing this, would it increase my risk to eat sweet potatoes cooked in aluminum foil?Even if there is a negligible risk, I still want to know for curiosity reasons.Thank You

- You are not eating the aluminum foil when wrap food in it to cook. There is little transference of aluminum to the food you eat. When using it for baked potatoes, the skins just slide off so the potato meat itself had not contact with the foil. Though I have also read something on the use of aluminum cooking vessels and aluminum foil having some properties that can be dangerous to our health, I could find no articles from the FDA or other such qualified organizations regarding the use of aluminum foil.

- Q: Aluminum plate thickness 1 cm, iron plate thickness 0.15 cm, area 1 square meters, thank you

- It's too difficult. Just think about it

- Q: How do aluminum sheets perform in terms of water resistance?

- Aluminum sheets generally exhibit excellent water resistance due to their natural oxide layer, which forms a protective barrier against corrosion. This oxide layer prevents water from penetrating the surface, making aluminum sheets highly resistant to water damage and rusting.

- Q: Can aluminum sheets be perforated for decorative or functional purposes?

- Yes, aluminum sheets can be perforated for both decorative and functional purposes. Perforating aluminum sheets involves creating a pattern of holes or perforations in the metal surface. These perforations can serve various purposes depending on the specific application. For decorative purposes, perforated aluminum sheets are commonly used in architecture and interior design. The patterns of holes can add visual interest and create unique designs, allowing for the play of light and shadow. It can be used for decorative screens, partitions, facades, and ceiling panels, among other applications. Perforated aluminum sheets offer versatility in design, as different hole sizes, shapes, and arrangements can be used to achieve the desired aesthetic effect. In terms of functional purposes, perforated aluminum sheets provide several advantages. Firstly, they can improve airflow and ventilation in applications such as HVAC systems, air-conditioning units, and speaker grilles. The perforations allow air to pass through while still maintaining the structural integrity of the sheet. Secondly, perforated aluminum sheets can be used for sound absorption and noise reduction. The holes in the sheet disrupt sound waves, reducing noise levels in areas such as auditoriums, concert halls, and industrial facilities. Additionally, perforated aluminum sheets have practical applications in filtration and separation processes. They can be used as screens or sieves to separate particles of different sizes, allowing for the filtration of liquids or gases. These sheets are also used in the manufacturing of various industrial equipment, such as vibrating screens, grain dryers, and centrifuges. In summary, aluminum sheets can indeed be perforated for both decorative and functional purposes. Whether it is to enhance the visual appeal of a space, improve airflow, reduce noise levels, or aid in filtration processes, perforated aluminum sheets offer a versatile solution for a wide range of applications.

- Q: There seems to be a load of buzz out there regarding the use of aluminum pots and pans. They apparently may cause Alzheimer’s or bone degeneration in women. I have some cast iron pans that I use when ever possible but they are not always practical. I’d like some of you kitchen pros to give me some sound advice regard the use of aluminum in the home kitchen. I know they are used in food service organizations.... I look forward to some informative replys.Thanks in advance.

- Your right it's like if you drink alot of soda or beer out of aluminum yes it's a fact that evetually it can cause health issues,i know i apologize for my spelling and it sucks.

- Q: Why does the glue of the aluminium curtain wall glue bubble? At the same time, do not bubble on the side glass, what is the reason?

- Brothers, there are several kinds of bubble gum, first to check is not part of the foam glue strip plug is not good, should be smooth, playing in a plastic bubble, not to leave the air, also can't have water, air water will bubble. In addition, glue when the temperature is very important no, when hot hit. Glue master experience play a decisive role, there is a great work in absolute don't let coolie, evenness and speed are very important.

- Q: Can aluminum sheets be painted?

- Indeed, it is possible to paint aluminum sheets. However, in order to ensure that the paint adheres well and lasts, some preparation may be necessary. The first and most crucial step involves thoroughly cleaning the surface of the aluminum sheet to eliminate any dirt, grease, or corrosion. This can be accomplished by employing a mild detergent and water or a specialized aluminum cleaner. Once cleaned, the surface should be completely dried before proceeding with the painting process. For enhanced paint adhesion, it is recommended to apply a primer specifically designed for use on aluminum. This primer will establish a bond between the aluminum surface and the paint, resulting in better adhesion and a longer-lasting paint job. Once the primer has dried, an appropriate paint can be applied to the aluminum sheet. It is important to select a paint that is compatible with aluminum and provides excellent adhesion and resistance to weather elements. Acrylic or epoxy-based paints are commonly utilized when painting aluminum. Before fully committing to the painting process, it is advisable to test a small inconspicuous area to ensure that the paint adheres properly and achieves the desired finish. Additionally, it is imperative to adhere to the manufacturer's instructions for the specific paint and primer being used, including adhering to proper drying times and application techniques. In conclusion, while it is possible to paint aluminum sheets, it is crucial to adequately prepare the surface, utilize an appropriate primer and paint, and follow the recommended procedures in order to achieve a long-lasting and visually appealing paint finish.

- Q: How do aluminum sheets handle extreme temperatures?

- Aluminum sheets have excellent thermal conductivity, allowing them to efficiently distribute and dissipate heat. They can withstand extreme temperatures without warping, melting, or becoming brittle, making them highly reliable in both high and low-temperature environments.

Send your message to us

Sheets of Metal Aluminum Ut 5052 Aluminum Sheet for Exterior Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords