Drywall Metal Stud and Track Gypsum Board Wall Partition

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 90000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,Structure of (Suspension System) Description

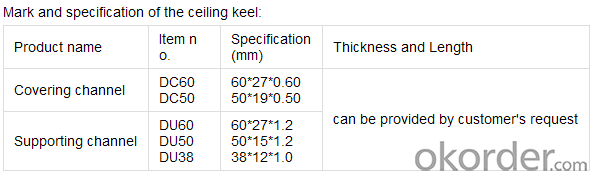

Main data

1.Zinc Galvanized&Snowflakes

2.High quality hot-dipped galvanized steel coil used

3.For ceiling and wall partition

4.Thichness:0.3mm-0.8mm

5.Length:3mm in common size

6.Color:Silver white

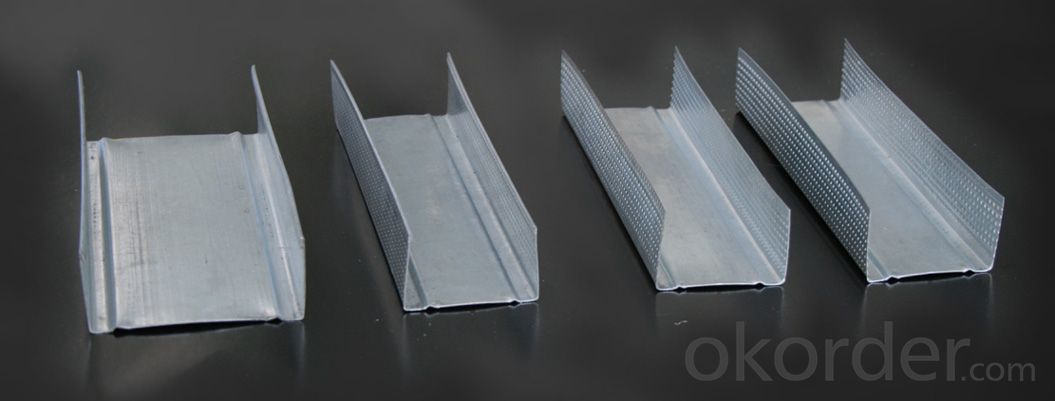

7.Shap:U and C shap

2,Main Features of the (Suspension System)

Ceiling channel and drywall channel, made of high-quality Snowflakes Steel, adopting laminose strut channel by Cold-formed Technology, are a kind of metal framework made after several continuous rolling. Ceiling keel and wall channel has light-weight, high-intensity, good-antisepsis and other advantages. They mainly match to paperbacked plasterboard and other goods, also the other plates such as GRC, FT and so on.

Advantages and Features:

1.Light,good strength,cauterization resistance and water resistance

2.Matching magnesium fire-proof board,gypsum board and many other wall and ceiling board

3.Moisure-proof ,shock-resistant,high-effcient and environmentally-friendly

4.Easy and fast for installation,time-saving

5. Prompt delivery, high quality ,competitive price and complete sets of styles

6.We can supply you the products based on your specific requirements

3,(Suspension System) Images

4,(Suspension System) Specification

5,FAQ of (Suspension System)

1.Superposition joint part between main carrier and vice carrier or vice carrier and carrier is called point lap.

2.It uses lap structure to assembly, connection between joints dovetail very well. The joint face

unknits and have a nice appearance.

3.There is a barb at the vice carrier joint, it can avoid loosing and falling from the infection of outside force.

4.Soleplate of main and vice carrier is zincification armor plate, which meets the national GB standard demand. We use baked paint zincifcation armor plate as baked paint panel,whoes capacity of zincification is high. It meet the national GB standard demand.

- Q: Can the interior walls be made of light steel keel partitions? Bathroom wall and interior wall with light steel keel wall is good or brick wall good?

- The interior walls can be made of light steel keel partitions, but the bathroom walls should be made of brick walls. The bathroom is generally water, wall with gypsum board, then the gypsum board will be bad water. So apply brick walls, and then paste the tiles on top.

- Q: How to install damping sound insulation felt

- 1, along the wall laying sound insulation felt, seam at the pressure seam processing; ???? 2, the installation of vibration keel, wedge around 600mm; keel gap filled with cotton; ???? 3, vibration-proof keel installed on the noise board (two-layer board clip insulation felt, sheet and sound insulation stitch treatment)

- Q: Is it good for brick walls or light walls?

- I suggest you use ceramic tiles, are light materials, you can hang light items (nails to be stuck in the gray seam, when the walls of the bottom of the three tiles should also use red brick, waterproof). If you have a fire on the request that use the gas block, red brick, lime sand brick, you can hang some of the items.

- Q: Light steel keel wall and wood which low cost

- Do with the wall, then, certainly with light steel keel production is better. As for the cost, can be used to do the wall of the board, it should be relatively thick, so that its price will be more than the price of gypsum board, and then the cost of light steel keel equivalent.

- Q: Light steel keel with what screws fixed gypsum board

- 2.5cm self-tapping screw! Do not matter where you can use nails. In foreign countries, taking into account the factors of the earthquake, heaven and earth keel and vertical keel can not be nailed.

- Q: Has installed a wooden floor, you can do in the above light steel keel wall?

- Do of course But I suggest do not do it! You do not want to move the floor, you put the floor cut off the partition of the piece. Directly to the disadvantages: 1: wooden floor flexible, partition instability. 2: you are not bad when the wall and the floor shut. 3: sound insulation is certainly worse

- Q: Light steel keel + gypsum board + surface brush latex paint partition wall per square meter offer is how much?

- Light steel keel about 12-13 yuan, enough to do a square, gypsum board per square 16 yuan (double) or so, paint workers wages about 25 yuan. / Square (package workers package material); Labor costs about 18 yuan, all offer for 75 yuan or so.

- Q: Light steel keel installed security door how loaded really

- It is recommended to install two square steel pipes vertically and fixed on the concrete floor and floor. The security door is mounted on the square steel pipe

- Q: 100 light steel keel 9.5mm thick gypsum board double double-sided partition three times, three times latex paint.

- The cost can not say ah, the material price is not the same ah, light steel keel brand and small brand, wall thickness is not the same, the price is not the same Finished putty powder is not different access, generally 0.6 yuan / kg or so; latex paint is not the same price, never less than 10 yuan / kg to 50 yuan / kg have. Rock wool about 10 yuan / m2, not much money auxiliary materials, together have 3 yuan / m2 are not used. Who knows what price to choose ah

- Q: With light steel keel gypsum board do partition wall price how to count?

- Light steel keel gypsum board to do partition wall artificial about 20 yuan, between 75 --- 120 offer, mainly to see your city and the quality of the material used to decide.

Send your message to us

Drywall Metal Stud and Track Gypsum Board Wall Partition

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 90000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords