3003 1060 Corrugated Aluminium Roofing Sheet

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

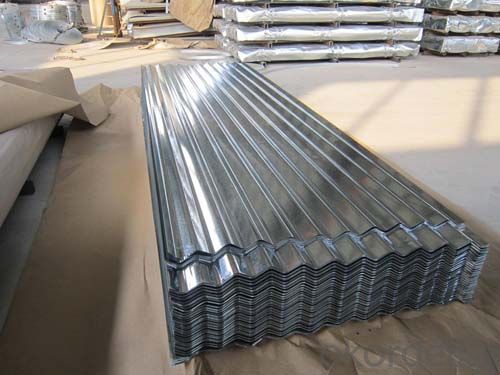

1. Specifications of 3003 1060 Corrugated Aluminium Roofing Sheet

name:corrugated aluminium sheet

alloy:1000,3000

thickness:0.4mm~1.5mm

width range: 1000mm-1500mm

2. Description of 3003 1060 Corrugated Aluminium Roofing Sheet

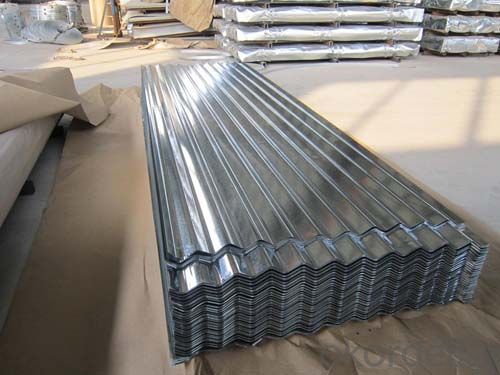

Aluminium Corrugated sheet are rippled metal sheets, primarily used at roofing, decking, and siding. Aluminum Corrugated sheet is tough, light weight, weather resistant and practical. We can produce aluminum corrugated roofing, siding, decking, and flooring for any application.

3. Package and shipping of 3003 1060 Corrugated Aluminium Roofing Sheet

standard export package or as per customer request

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

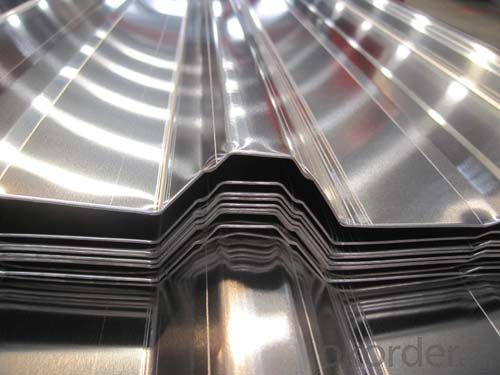

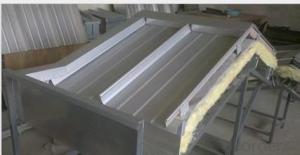

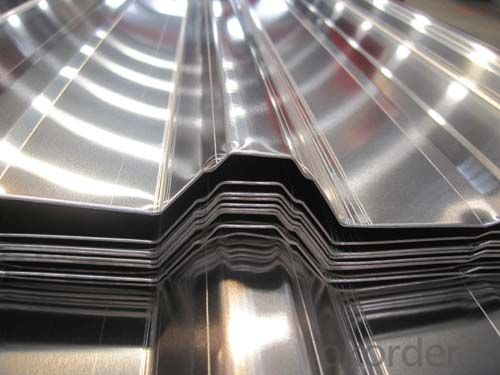

5. Image of 3003 1060 Corrugated Aluminium Roofing Sheet

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

8. Key Specifications/Special Features

1. Aluminum roofing sheets 2. 3003, h44. 3. Color coated as ral color chart. 4. Widely used as ware, garage roofing sheets. 3003, h44 aluminum roofing sheets can be color coated as ral color chart. It's the most widely used roofing materials in warehouse, garage for roofing sheets. We have many customers like in affrica,. During the entire production process of aluminium coating sheet from pre-treatment to finished product, we use international famous quality raw and auxiliary materials, for example aluminum sheets from the famous xinan aluminum industry and some other famous aluminum industry in china, pre-treatment made of ... With the famous germany henkel & chemtell from germany, above 70% pvdf from ppg co.,usa and the polyester coating from sweden becker industrial coating co. With the most advanced equipment and production technology, as well as top raw made of ... Brands, we produce high-quality and reliable colorful aluminium coating sheet. Theyve been widely used on the high-grade aluminum composite panel industry, now we take a lions market share and become one of the largest manufacturers in the face of the earth. Specification:. Coating type: pe (polyester resin) made of ... And pvdf (polyvinylidene fluoride) made of ... . Thickness: 0.2 ~ 1.2 mm,. Width: 800 ~ 1520 mm,. Annual production capacity: 8000 tons.

- Q: Are aluminum sheets suitable for pharmaceutical packaging?

- Yes, aluminum sheets are suitable for pharmaceutical packaging due to their excellent barrier properties, light weight, and resistance to corrosion. They protect pharmaceutical products from moisture, light, and oxygen, ensuring their stability and extending their shelf life. Additionally, aluminum sheets can be easily molded into different shapes, making them a versatile choice for various packaging formats in the pharmaceutical industry.

- Q: Describe the steps involved in installing aluminum sheets on a roof.

- <p>Installing aluminum sheets on a roof involves several key steps: 1) Inspect the roof structure to ensure it can support the new material. 2) Remove any existing roofing material. 3) Install roof underlayment to protect against moisture. 4) Position the first aluminum sheet at the lowest point of the roof, aligning it with the eaves. 5) Secure the sheet using clips or screws, ensuring a watertight seal. 6) Continue installing sheets up the roof, overlapping each by at least 2 inches for a secure fit. 7) Cut and fit sheets around vents, pipes, and other roof protrusions. 8) Install flashing and trim to finish edges and seal the roof. 9) Check for proper alignment and secure all fasteners. 10) Clean up debris and inspect the installation for any gaps or leaks.</p>

- Q: Are aluminum sheets lightweight?

- Yes, aluminum sheets are lightweight due to the low density of aluminum, making them ideal for various applications where weight is a concern.

- Q: How does the price of 101 aluminum sheets compare to other aluminum alloys?

- The price of 101 aluminum sheets can vary depending on various factors such as market conditions, demand, and supply. However, generally speaking, 101 aluminum alloy is considered to be one of the most affordable options among aluminum alloys. It is often chosen for its relatively low cost and good overall performance. Compared to other aluminum alloys, especially high-strength alloys such as 7075 or 6061, the price of 101 aluminum sheets tends to be lower. This is because 101 aluminum is a relatively simple alloy with a lower composition of alloying elements, making it less expensive to produce. However, it is important to note that the price differentiation between aluminum alloys can vary depending on current market conditions and specific requirements. Factors such as the thickness, size, and quantity of sheets required can also impact the final price. Therefore, it is always recommended to check with suppliers or manufacturers to get the most accurate and up-to-date pricing information for 101 aluminum sheets compared to other aluminum alloys.

- Q: What type of aluminum plate does it contain?

- The 3 * * * series aluminum plate is mainly composed of manganese, and the content is between 1.0-1.5%.4 * * * series aluminum sheet: stands for 4A01. The 4 * * * series aluminum plate belongs to a series with high silicon content.5 * * * series aluminum sheet: stands for 5052, 5005, 5083, 5A05 series.

- Q: Can aluminum sheets be used for industrial shelving?

- Yes, aluminum sheets can be used for industrial shelving. Aluminum is a lightweight and durable material that is resistant to corrosion, making it suitable for various industrial applications, including shelving. It offers strength and stability while being easy to clean and maintain. Additionally, aluminum's versatility allows for customization and modification to fit specific storage needs.

- Q: Can the aluminum sheets be used in the construction industry?

- Yes, aluminum sheets can definitely be used in the construction industry. Aluminum is a versatile and lightweight material that offers several advantages for construction applications. It is corrosion-resistant, which makes it ideal for outdoor structures and buildings. Aluminum sheets are commonly used for roofing, siding, window frames, doors, and other architectural elements. Additionally, aluminum's high strength-to-weight ratio allows for the construction of durable and efficient structures. Its malleability also makes it easy to fabricate and shape into various forms, allowing for creative and innovative designs in construction projects. Overall, aluminum sheets are a popular choice in the construction industry due to their durability, versatility, and aesthetic appeal.

- Q: Can aluminum sheets be bent or formed?

- Indeed, it is possible to bend or shape aluminum sheets. Aluminum, being a remarkably malleable and ductile metal, can be effortlessly molded or bent without fracturing. This attribute renders it a favored option for a wide range of purposes, including the production of automotive components, aircraft structures, and household products. Diverse techniques, such as press braking, roll bending, and stretch forming, can be employed to bend or shape aluminum sheets. By utilizing these methodologies, the aluminum sheets can be formed into diverse angles or curves to fulfill precise design prerequisites.

- Q: What is aluminum sheet material L2?

- L2 is the name of the brand of aluminium plate in our country, which is the 1060 brand now!L1 is 1070L2 is 1060L3 is 1050L4 is 1030L5-1 is 1100And LF-21, or 3003, LF-1, or 3004! Wait

- Q: What are the different types of aluminum sheets?

- There are several different types of aluminum sheets available, each with its own unique characteristics and applications. Here are some of the most common types: 1. Plain aluminum sheet: This is the most basic type of aluminum sheet, characterized by its smooth surface and uniform thickness. It is widely used in various industries for general purposes. 2. Embossed aluminum sheet: This type of sheet has a textured or patterned surface, which is achieved by rolling the aluminum through a patterned roller. It is commonly used for decorative purposes, such as in interior design or automotive trim. 3. Perforated aluminum sheet: As the name suggests, this type of sheet contains small holes or perforations throughout its surface. It is often used in architectural applications, such as building facades or sunscreens, as well as in filtration systems. 4. Treadplate aluminum sheet: Also known as checker plate or diamond plate, this sheet has a raised pattern of lines or diamonds on its surface. This pattern provides added traction and makes it suitable for applications where slip resistance is important, such as industrial flooring or stair treads. 5. Anodized aluminum sheet: Anodizing is an electrochemical process that forms a protective oxide layer on the surface of the aluminum, making it more durable, corrosion-resistant, and able to accept dyes for color customization. Anodized aluminum sheets are commonly used in architectural applications, signage, and consumer products. 6. Painted aluminum sheet: This type of sheet is coated with a layer of paint, which not only enhances its appearance but also provides additional protection against corrosion. It is often used in applications where aesthetics are important, such as building facades, signage, or automotive parts. These are just a few examples of the different types of aluminum sheets available in the market. The choice of the right type depends on the specific requirements of the project, such as durability, appearance, corrosion resistance, or slip resistance.

Send your message to us

3003 1060 Corrugated Aluminium Roofing Sheet

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords