Aluminum AW-3003 PE Aluminium Composite Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of EN AW - 3003 PE Aluminium Composite Panel Description

EN AW - 3003 PE Aluminium Composite Panel is one semi-finished aluminium material. This coil can be rolled down to aluminium coil,sheet,circle ect. The alloy AA3105 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of EN AW - 3003 PE Aluminium Composite Panel

EN AW - 3003 PE Aluminium Composite Panel | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

3. Application of EN AW - 3003 PE Aluminium Composite Panel

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of EN AW - 3003 PE Aluminium Composite Panel

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of EN AW - 3003 PE Aluminium Composite Panel

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

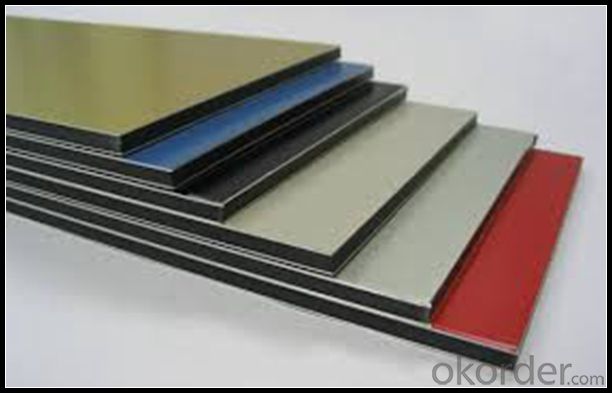

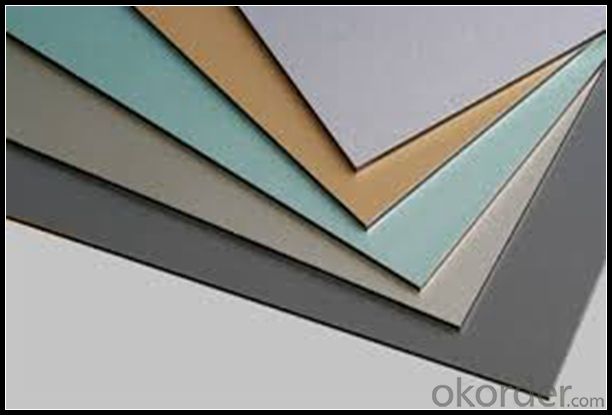

6. Image of EN AW - 3003 PE Aluminium Composite Panel

7. Package and shipping of EN AW - 3003 PE Aluminium Composite Panel

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: This question asks about the various uses of aluminum alloys within the construction industry.

- <p>Aluminum alloys are widely used in construction due to their strength, light weight, and corrosion resistance. Some applications include: 1) Structural framing for buildings and bridges, leveraging their high strength-to-weight ratio. 2) Window and door frames, benefiting from their durability and low maintenance. 3) Roofing materials, as they are lightweight and resistant to weathering. 4) Facade cladding, for aesthetic appeal and resistance to environmental damage. 5) Electrical wiring and conduits, due to their excellent electrical conductivity and safety. 6) Scaffolding, as they are lightweight and easy to assemble. 7) Solar panel frames, taking advantage of their lightweight and recyclable properties. These applications highlight aluminum alloys' versatility and importance in modern construction.</p>

- Q: This question asks whether it is safe to use aluminum cookware for pregnant women or individuals with health conditions.

- <p>While aluminum cookware is generally safe for most people, there are concerns about its potential health effects. Aluminum has been linked to cognitive issues and Alzheimer's disease, although the evidence is not conclusive. For pregnant women and those with health conditions, it is advisable to err on the side of caution. Opt for cookware made from stainless steel, cast iron, or non-stick materials without aluminum. If you must use aluminum cookware, avoid acidic or alkaline foods and ensure the cookware is not scratched, as this can increase aluminum leaching into food.</p>

- Q: This question asks about the chemical reaction between aluminum and elements in the halogen group.

- <p>Aluminum reacts with halogens to form aluminum halides. The reaction is typically exothermic and can be represented by the general equation: 2Al + 3X2 鈫?2AlX3, where X represents a halogen (fluorine, chlorine, bromine, iodine, or astatine). For example, when aluminum reacts with chlorine, it forms aluminum chloride (AlCl3). The reaction is often initiated by heating the aluminum, which is then rapidly oxidized by the halogen. This process is used industrially to produce aluminum halides, which are important in various chemical applications.</p>

- Q: This question asks about the impact of weathering on aluminum surfaces, including potential changes and effects.

- <p>The weathering process can significantly affect aluminum surfaces. Aluminum naturally forms a protective oxide layer when exposed to air, which provides corrosion resistance. However, over time, weathering can lead to the thinning or damage of this oxide layer, especially in harsh environments. This can result in corrosion, pitting, or discoloration. Additionally, weathering can cause physical changes such as surface roughening due to the differential erosion of the aluminum and its protective layer. In coastal areas, the presence of salt can accelerate these effects. Proper maintenance, such as regular cleaning and protective coatings, can help mitigate the effects of weathering on aluminum surfaces.</p>

- Q: Describe the characteristics and properties of aluminum oxide.

- <p>Aluminum oxide, also known as alumina, is a compound of aluminum and oxygen with the chemical formula Al2O3. It is a white solid that is insoluble in water but soluble in acid and base. It has a high melting point (over 2000掳C), high hardness, and is chemically inert. Aluminum oxide is also a good electrical insulator and has a high refractive index. It is used in various applications, including abrasives, refractory materials, and as a catalyst in chemical processes. Additionally, it is biocompatible and is used in medical implants and dental materials.</p>

- Q: Is there an alternative method for recycling aluminum besides the conventional recycling process?

- <p>Yes, aluminum can be recycled in different ways. Apart from the conventional recycling process, which involves melting and recasting, there are innovative methods being explored. One such method is mechanical recycling, where aluminum is cleaned, sorted, and processed into new products without melting. Another approach is chemical recycling, which breaks down aluminum into its constituent elements and then reassembles them into new materials. These alternative methods aim to reduce energy consumption and environmental impact while still effectively recycling aluminum.</p>

- Q: This question asks if there are differences in how long different types of aluminum cookware can last.

- <p>Yes, there are differences in the durability of different types of aluminum cookware. Anodized aluminum cookware is more durable and resistant to scratches and corrosion compared to non-anodized aluminum. Cast aluminum cookware is heavier and more durable than aluminum clad cookware, which is a layer of aluminum bonded to a stainless steel core. The thickness of the aluminum also affects durability, with thicker aluminum being more resistant to warping and lasting longer. Proper care and maintenance also play a significant role in the longevity of aluminum cookware.</p>

- Q: Is it possible to use aluminum as a material in the construction of solar panels?

- <p>Yes, aluminum is commonly used in solar panels. It is utilized in the frame of the solar panel to provide structural support and protection. Aluminum is chosen for its lightweight, high strength, and resistance to corrosion, which are beneficial properties for outdoor applications like solar panels. It also helps in heat dissipation, which is crucial for maintaining the efficiency of the solar cells. While aluminum is not a primary component of the photovoltaic cells themselves, its role in the overall structure is significant.</p>

- Q: This question asks for an overview of the environmental concerns associated with the manufacturing process of aluminum.

- <p>The production of aluminum is associated with several environmental issues. One major concern is the high energy consumption required for the smelting process, which contributes to greenhouse gas emissions. The process also generates significant amounts of waste, including red mud, a hazardous byproduct that can contaminate soil and water if not properly managed. Additionally, deforestation and habitat destruction occur due to the mining of bauxite, the primary ore of aluminum. Air pollution is another issue, as the production process releases particulates and other pollutants into the atmosphere. Lastly, the depletion of non-renewable resources, such as fossil fuels used in the smelting process, is a long-term environmental concern related to aluminum production.</p>

- Q: This question asks whether the energy consumption for producing recycled aluminum is lower compared to the production of new aluminum.

- <p>Yes, producing recycled aluminum requires significantly less energy than producing new aluminum. Recycling aluminum uses only about 5% of the energy needed to produce primary aluminum from bauxite ore. This is because recycling involves melting and recasting the metal, which is a much less energy-intensive process than mining, refining, and smelting new aluminum. As a result, recycling aluminum helps conserve energy and reduces greenhouse gas emissions associated with aluminum production.</p>

Send your message to us

Aluminum AW-3003 PE Aluminium Composite Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords