Grade AISI D2 Hot Rolled Steel Flat Bar with Low Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Grade AISI D2 Hot Rolled Steel Flat Bar with Low Price

Specification of Grade AISI D2 Hot Rolled Steel Flat Bar with Low Price

Grades | GB | DIN | AISI | JIS | OTHERS | |||||

Cr12Mo1V1 | 1.2379 | D2 | SKD11 | K110 | ||||||

X155CrVMo12-1 | ||||||||||

Chemical composition | C | Si | Mn | Cr | P | S | Mo | V | ||

1.50-1.60 | 0.10-0.40 | 0.15-0.45 | 11.50-12.50 | 0.03MAX | 0.03MAX | 0.60-0.80 | 0.90-1.10 | |||

Available | Round Bar | Diameter | Length | |||||||

10-380mm | 2000-5800mm | |||||||||

Flat Bar | Thickness | Width | Length | |||||||

12-500mm | 60-900mm | 2000-5800mm | ||||||||

Surface condition | Black surface/ Milled | |||||||||

Annealed hardness | HB250MAX | |||||||||

Characteristics | Very high resistance against abrasive and adhesive wear due to a high volume of hard carbides in the steel matrix moderate machinability good dimensional stability, toughness and through hardenability | |||||||||

Applications | cutting, punching, stamping tools | |||||||||

Shear blades | ||||||||||

Thread rolling dies | ||||||||||

Drawing and bending tools | ||||||||||

Flanging and straightening rolls | ||||||||||

Fine cutting tools | ||||||||||

Deep drawing tools | ||||||||||

Plastic mould for abrasive polymers | ||||||||||

Cold extrusion dies | ||||||||||

Drawing dies | ||||||||||

CNBM Introduction of Grade AISI D2 Hot Rolled Steel Flat Bar with Low Price

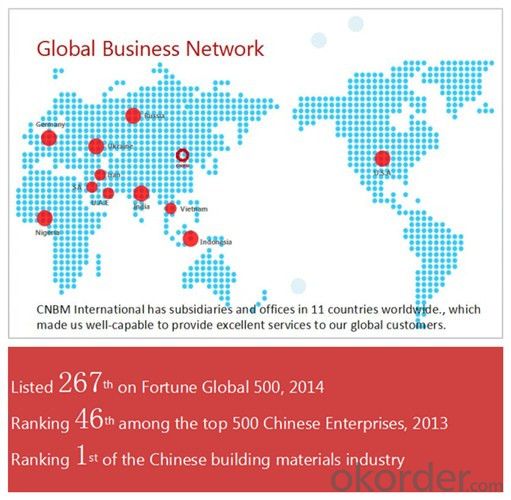

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

After-sale service |

|

Advantages

|

|

Packaging & Delivery of Grade AISI D2 Hot Rolled Steel Flat Bar with Low Price

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

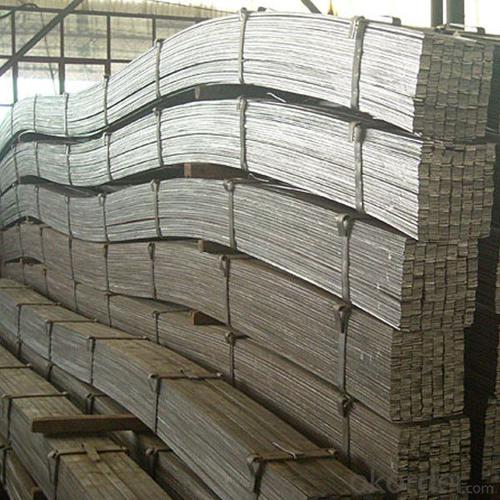

Products Show

FAQ:

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust

|

Where are your Market? | Covering more than 160 countries in the world |

- Q: How does special steel perform in terms of creep resistance?

- Special steel typically performs very well in terms of creep resistance. Due to its unique composition and heat treatment, it can withstand high temperatures and prolonged stress without deforming or failing. This makes it an excellent choice for applications that require long-term stability under extreme conditions, such as in power plants or aerospace industry.

- Q: How is special steel used in the production of cutting blades?

- Special steel is used in the production of cutting blades due to its exceptional properties, such as high hardness, toughness, and wear resistance. These properties allow the cutting blades to maintain their sharpness and durability even when subjected to intense cutting forces and repeated use. The special steel's composition and heat treatment processes ensure that the cutting blades are capable of withstanding harsh operational conditions, resulting in efficient and precise cutting performance across various industries, including manufacturing, construction, and agriculture.

- Q: What are the challenges in forging special steel?

- Forging special steel presents several challenges, including selecting the appropriate alloy composition, achieving the desired mechanical properties, and maintaining dimensional accuracy during the forging process. Additionally, special steels often have higher carbon content and alloying elements, making them more prone to cracking, distortion, and heat treatment issues. Controlling the heating and cooling rates, as well as precise temperature management, is crucial to avoid defects and ensure uniformity. Furthermore, the intricate shapes and complex geometries of special steel components require skilled craftsmanship and sophisticated forging techniques to achieve the desired final product quality.

- Q: What are the properties of structural steel?

- Structural steel possesses several key properties that make it an ideal material for construction. Firstly, it has high strength, allowing it to bear heavy loads and resist deformation. Additionally, it exhibits excellent ductility, meaning it can be easily shaped without breaking. Structural steel is also highly durable and corrosion-resistant, providing long-lasting stability to buildings and structures. Moreover, it offers versatility in terms of design and construction methods. Finally, it is a sustainable and recyclable material, making it environmentally friendly. Overall, the properties of structural steel contribute to its widespread use in various construction projects.

- Q: How is special steel used in the manufacturing of bearings?

- Special steel is used in the manufacturing of bearings due to its high strength, durability, and resistance to wear and corrosion. This type of steel is specifically designed to withstand the demanding conditions and loads that bearings are subjected to. It is used to create the inner and outer rings, as well as the rolling elements, of the bearing, ensuring smooth operation and increased lifespan.

- Q: What are the different methods of preventing hydrogen embrittlement in special steel?

- There are several methods that can be employed to prevent hydrogen embrittlement in special steel. These include proper material selection, such as using low-hydrogen alloys or stainless steel grades that are less susceptible to embrittlement. Additionally, controlling the environment during manufacturing and storage processes is crucial, as hydrogen absorption can occur during these stages. Other preventive measures include heat treatment processes like stress relieving and tempering, which can help reduce internal stresses and enhance the steel's resistance to embrittlement. Overall, a combination of careful material selection, controlled environments, and appropriate heat treatment techniques can effectively prevent hydrogen embrittlement in special steel.

- Q: How is special steel used in the production of surgical instruments?

- Special steel is used in the production of surgical instruments due to its unique properties such as corrosion resistance, high strength, and durability. This type of steel is specifically designed to withstand the harsh conditions of surgical procedures, ensuring the instruments remain sharp, sterile, and reliable. The use of special steel in surgical instruments guarantees precision and quality, ultimately enhancing the safety and effectiveness of medical procedures.

- Q: How does special steel contribute to national security?

- Special steel contributes to national security in several ways. Firstly, it is used in the manufacturing of weapons and defense equipment, providing the military with advanced and high-performance materials for their operations. This includes the production of armored vehicles, submarines, aircraft carriers, and missile systems, enhancing a country's defense capabilities. Additionally, special steel is essential in the construction of critical infrastructure, such as bridges, power plants, and communication networks, which are vital for national security. Overall, special steel plays a crucial role in strengthening a nation's defense industry and infrastructure, thereby contributing significantly to national security.

- Q: Can special steel be used in railway applications?

- Railway applications often utilize special steel, which is also referred to as alloy steel or high-strength steel. This type of steel possesses distinct characteristics that make it suitable for a wide range of demanding applications, including railways. Its exceptional strength, durability, and resistance to wear make it an ideal choice for railway components that endure high loads, vibrations, and extreme conditions. In the realm of railway applications, special steel is commonly employed in the manufacturing of rails, wheels, axles, and other crucial components. Rails crafted from special steel have the ability to handle heavy train traffic while providing a smooth and stable ride, all the while resisting wear and deformation. Special steel wheels and axles offer remarkable strength and toughness, ensuring safe and dependable operation even under heavy loads and high-speed conditions. Furthermore, special steel is frequently utilized in the construction of railway bridges, tunnels, and other infrastructure projects. Its exceptional strength and resistance to corrosion and fatigue make it suitable for supporting heavy trains and withstanding the environmental challenges associated with railway construction. Moreover, the utilization of special steel in railway applications can result in cost savings and efficiency improvements. Its high durability and wear resistance minimize the need for frequent maintenance and replacement, leading to reduced maintenance costs and an extended service life for railway components. In conclusion, special steel possesses the necessary strength, durability, and performance required for railway applications. Its unique properties make it an ideal choice for ensuring the safety, reliability, and efficiency of rail transportation systems.

- Q: What are the different welding methods used for special steel?

- There exists a range of welding methods that can be utilized for special steel, contingent upon the specific needs of the project. Some of the commonly employed welding methods for special steel comprise the following: 1. Gas Metal Arc Welding (GMAW): Also known as MIG welding, this technique employs a consumable electrode and a shielding gas to safeguard the weld against atmospheric contamination. GMAW is advantageous for welding special steel due to its ability to produce high-quality welds with minimal spatter. 2. Gas Tungsten Arc Welding (GTAW): Also known as TIG welding, this method employs a non-consumable tungsten electrode and a shielding gas to protect the weld. GTAW is frequently employed for special steel as it allows for precise control during the welding process, resulting in defect-free, high-quality welds. 3. Shielded Metal Arc Welding (SMAW): Also known as stick welding, this technique utilizes a consumable electrode coated in flux to shield the weld. SMAW is widely employed for special steel due to its versatility and portability, making it suitable for various positions and environments. 4. Flux-cored Arc Welding (FCAW): This method employs a tubular electrode filled with flux to safeguard the weld. FCAW is often utilized for special steel due to its ability to achieve high deposition rates and deep penetration, making it suitable for thicker materials. 5. Submerged Arc Welding (SAW): This technique employs a continuously fed wire electrode and a granular flux applied around the weld. SAW is commonly used for special steel as it can produce high-quality welds in thick sections. It is crucial to consider various factors, such as the type and thickness of the steel, the desired weld quality, and the specific application requirements, when selecting the appropriate welding method for special steel. Therefore, it is advisable to consult with welding professionals or engineers to determine the most suitable method for a particular project involving special steel.

Send your message to us

Grade AISI D2 Hot Rolled Steel Flat Bar with Low Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords