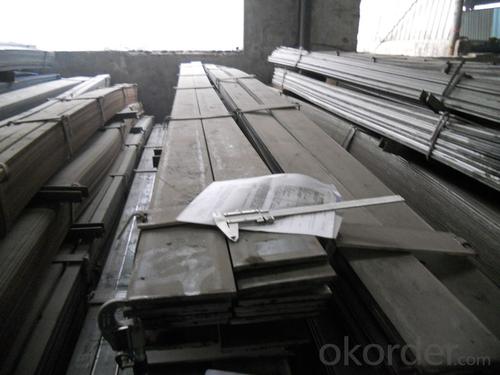

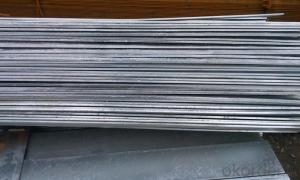

Wholesale hot rolled steel flat bar with lowest price

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1passed the ISO9001:2000

2steel manufacturer,30 years experience

3near the seaport ,low cost

4good reputation and service

Carbon steelsdo rust easily, but they can be easily painted or primed. They are cheap so they are the normal choice for most

fabrications. Mild Steel can be easily cut or drilled to meet your requests.

Mild Steel Flat Bar is generally used for fabrication, frameworks and for structural items. Such as:

Plastic moulds, cold work die and mould base as well as constructional part .

Automobile manufacturing( Auto girders special steel

Shipping manufacture

Railway special pad

Mechanical steel

section size: axb=(650-580)x(6-50)

lenght : 6m/9m/12m or as required

Chemical composition of Q235

Alloy No | Grade | Element(%) | ||||

C

| Mn

| S

| P

| Si

| ||

Q235

|

B

|

0.12—0.20 |

0.3—0.7 |

≤0.045 |

≤0.045

|

≤0.3

|

Physical properties of Q235

Alloy No | Grade | Yielding strength point(Mpa) | Tensile strength (Mpa) | Elongation after fracture(%) | ||||||

Thickness (mm) | Thickness (mm) | |||||||||

≤16 | >16--40 | >40--60 | >60--100 | ≤16 | >16--40 | >40--60 | >60--100 | |||

≥ | ≥ | |||||||||

Q235 |

B |

235 |

225 |

215 |

205 |

375--500 |

26 |

25 |

24 |

23 |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

- Q: How do you determine the fracture toughness of a steel flat bar?

- There are various methods available to determine the fracture toughness of a steel flat bar. However, the most common and reliable technique is the ASTM E399 standard test method, also known as the "Standard Test Method for Plane-Strain Fracture Toughness of Metallic Materials." To conduct the ASTM E399 test method, a test called the "Charpy V-notch test" or the "standard test specimen" test is performed. This involves subjecting a rectangular specimen with a V-shaped notch to impact using a swinging pendulum. The specimen is clamped at both ends, and the pendulum strikes the center, causing it to fracture. During this fracture, the energy absorbed by the specimen is recorded and used to calculate the fracture toughness. This calculation takes into account the dimensions of the specimen, the energy absorbed, and the geometry of the V-notch. It's important to note that the ASTM E399 test method is specifically designed for determining plane-strain fracture toughness. This refers to the fracture toughness under conditions where the deformation is primarily two-dimensional, and the stress is evenly distributed across the thickness of the specimen. This is usually the case for flat bars with a width much larger than the thickness. By following the ASTM E399 standard test method, manufacturers, researchers, and engineers can accurately determine the fracture toughness of a steel flat bar. This information is crucial for evaluating the material's ability to resist crack initiation and propagation. It plays a vital role in the design of safe and reliable structures and components.

- Q: Difference between cold drawn flat steel and flat steel

- Cold drawn flat steel: steel, smooth surface,Flat steel: steel is relatively soft, flatness, no cold drawn flat steel

- Q: Can steel flat bars be hardened or tempered?

- Steel flat bars can indeed undergo hardening or tempering. Hardening entails heating the steel to a specific temperature and rapidly cooling it, typically through water or oil quenching. This procedure alters the steel's molecular structure, resulting in heightened hardness and resistance against wear and deformation. Conversely, tempering takes place after hardening and involves reheating the steel to a lower temperature, followed by slow cooling. This step aids in alleviating internal stresses and enhancing the steel's toughness and ductility, rendering it less brittle and more suitable for certain applications. To achieve desired mechanical properties, both hardening and tempering can be employed on steel flat bars. It is important to note, however, that the particular hardening or tempering method and parameters may differ depending on the type of steel utilized and the desired outcome.

- Q: Are steel flat bars available in different colors?

- Steel flat bars do not come in various colors, I'm afraid. Usually, steel is manufactured with its inherent grey hue due to its composition and production process. Nonetheless, it is feasible to alter the color of steel flat bars by applying diverse coatings or paint. These coatings can offer extra defense against rust or purely serve aesthetic intentions.

- Q: Are steel flat bars suitable for the construction of retail spaces or shopping centers?

- Yes, steel flat bars are suitable for the construction of retail spaces or shopping centers. They are strong, durable, and can be easily fabricated and installed. Steel flat bars also provide stability and support to the structure, making them an ideal choice for commercial construction projects.

- Q: What are the advantages of using steel flat bars over other materials?

- There are several advantages of using steel flat bars over other materials. Firstly, steel is known for its exceptional strength and durability, which makes it suitable for heavy-duty applications. It can withstand high levels of stress and is resistant to bending or warping. Secondly, steel flat bars offer excellent corrosion resistance, ensuring longevity and reducing maintenance costs. Additionally, steel is widely available and cost-effective compared to alternative materials like aluminum or titanium. Lastly, steel's versatility allows for various applications, including construction, manufacturing, and fabrication, making it a preferred choice for many industries.

- Q: What are the typical tolerances for steel flat bars?

- The tolerances for steel flat bars can vary depending on the specific industry and application. Typically, the standard tolerances for steel flat bars are +/- 1/8 inch. This means that the steel flat bars can deviate by up to 1/8 inch from the specified dimensions. It is important to consider that these tolerances can be influenced by factors such as the manufacturing process, the grade of steel used, and any additional specifications or requirements from the customer or industry standards. For precise applications or industries that require high accuracy and consistency, tighter tolerances may be necessary. In such cases, the tolerances for steel flat bars can be specified more precisely, such as +/- 0.005 inches or even tighter. Ultimately, the specific tolerances for steel flat bars will depend on the project requirements, industry standards, and the capabilities of the manufacturer. It is recommended to consult relevant standards or work with a trusted supplier to ensure that the tolerances meet the desired specifications for a particular application.

- Q: What are the weight and load-bearing capacities of different steel flat bar sizes?

- The weight and load-bearing capacities of different steel flat bar sizes vary depending on the specific dimensions and quality of the steel used. Generally, larger and thicker flat bars have higher weight and load-bearing capacities. To determine the exact capabilities, it is necessary to consult engineering tables or reference materials that provide specific load ratings for different steel flat bar sizes.

- Q: What is the typical hardness of steel flat bars?

- Steel flat bars can exhibit varying levels of hardness, contingent upon their respective grade and heat treatment. Typically, these hardness levels span from 40 to 65 on the Rockwell hardness scale. This range of hardness guarantees the strength and durability of steel flat bars, enabling them to endure diverse mechanical pressures and impacts. Nevertheless, it is essential to acknowledge that the hardness can be tailored to meet specific application demands by means of distinct heat treatment procedures.

- Q: Can steel flat bars be used for making packaging machinery or equipment?

- Steel flat bars have the capability to be utilized in the production of packaging machinery or equipment. As a robust and long-lasting material, steel can endure the substantial loads and elevated velocities commonly necessary in packaging machinery. The malleability and weldability of steel flat bars allow for the effortless formation and fusion of the essential components and structures required in packaging equipment. Moreover, steel possesses exceptional corrosion resistance, rendering it appropriate for implementation in packaging machinery that may encounter moisture or rigorous environments. In conclusion, steel flat bars present a versatile and dependable option for the manufacturing of packaging machinery or equipment.

Send your message to us

Wholesale hot rolled steel flat bar with lowest price

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords