Grade A36 SS400 Hot Rolled Steel Coil _HR Coil for Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Grade A36 SS400 Hot Rolled Steel Coil _HR Coil for Construction

Specification

Product | Hot Rolled Steel Coil |

Place of origin | Tianjin, China |

MOQ | 25 tons |

Thickness | 1.0mm-80mm |

Width | 600mm-3000mm |

Length | In coil, 3000-15000mm |

Application | Construction of vessels, containers, buildings, |

roads, railways, other infrastructure, appliances, | |

and so on. | |

Standard | AISI, ASTM, BS, DIN, JIS, GB, etc |

Grade | A572,A573,A633,A678,A709,A710,G3101,G3136 |

Type | Steel Coil |

Surfacing | Vanished, painted, oiled or as request |

Technology | Hot Rolled |

Payment Terms | L/C,T/T, Western Union, Money Gram |

Product Ability | 5000 tons per month |

Delivery | Within 15-30 days upon receipt of L/C or deposits |

Packing | Standard seaworthy export packing or as the request of customers |

Name | Hot Rolled Steel Coil |

Standard | GB/ASTM/SAE/AISI/DIN/JIS/EN/BS |

Surface Treatment: | Black/Peeling/Polished/Machined |

Delivery Condition: | Hot Rolled or Forged/Peeled or Black Surface |

Test | SGS/UT 100% Elements Testing |

Certificate: | ISO/Mill Certificate |

Service: | 24 hours online service / |

more than 20 years trading and manufacture | |

Quality Assurance: | the third party inspection, such as SGS, BV, TUV…etc. is acceptable |

Packaging Details: | Seaworthy Packaging or as per customer's packing instruction |

Chemical Composition

| Chemical Composition | ||||

C | Si | Mn | P | S | |

Q345B | ≤0.20 | ≤0.55 | 1.00-1.60 | ≤0.040 | ≤0.040 |

Q345C | ≤0.20 | ≤0.55 | 1.00-1.60 | ≤0.035 | ≤0.035 |

Q345D | ≤0.18 | ≤0.55 | 1.00-1.60 | ≤0.030 | ≤0.030 |

Company Information

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

After-sale service | l CNBM provides the services and support you need for every step of our cooperation. We’re the business partners you can trust; you can relax and get on with doing business. |

l For any problem, please kindly contact us at any your convenient time, we’ll reply you in our first priority within 24 hours | |

Advantages | Industry experience over 20 years. |

Shipment of goods -More than 70 countries worldwide. | |

The most convenient transport and prompt delivery. | |

Competitive price with best service. | |

High technical production line with top quality products. | |

High reputation based on best quality products. |

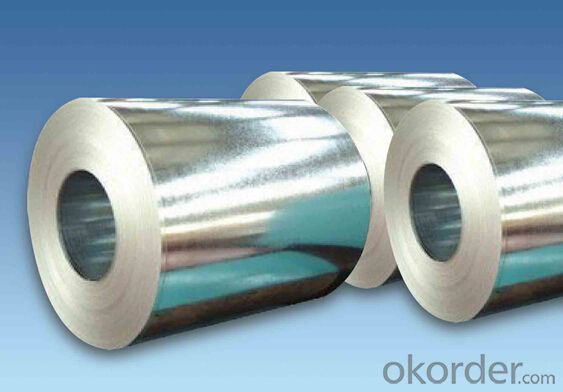

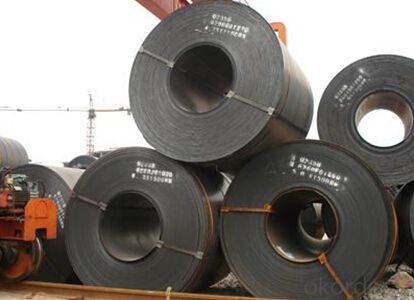

Product Show

FAQ

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. |

Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. | |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust |

Where are your Market? | Covering more than 160 countries in the world |

- Q: How does stainless steel contribute to the construction industry?

- Stainless steel contributes to the construction industry by providing durability, corrosion resistance, and aesthetic appeal. Its strength and resistance to rust make it ideal for structural components, such as beams, columns, and reinforcement bars. Stainless steel is also commonly used for architectural elements like cladding, handrails, and fixtures due to its sleek appearance and low maintenance requirements. Overall, stainless steel enhances the longevity and aesthetics of buildings, making it a valuable material in the construction industry.

- Q: Can special steel be used for electrical applications?

- Yes, special steel can be used for electrical applications. Special steel alloys, such as stainless steel or electrical-grade steels, are often used in electrical applications due to their excellent electrical conductivity, resistance to corrosion, and high strength properties. These steels are commonly utilized in the manufacturing of electrical components, wiring, transformers, and various electrical equipment.

- Q: What are the common challenges in heat treating special steel?

- Heat treating special steel can present a variety of challenges. One common challenge is achieving the desired hardness and strength while maintaining the desired microstructure. Special steels often require specific heat treatment processes, such as quenching and tempering, to achieve the desired mechanical properties. However, the high alloy content of these steels can lead to difficulties in achieving uniform heat distribution and controlling the cooling rate during quenching, which in turn can result in inconsistent hardness and potential distortion. Another challenge in heat treating special steel is managing residual stresses. During the heating and cooling process, differential thermal expansion and contraction can cause stress to build up within the steel, leading to potential cracking or distortion. Special care must be taken to minimize these stresses through proper heat treatment techniques, such as preheating and controlled cooling rates. Special steels often have stringent cleanliness requirements, as impurities or non-metallic inclusions can negatively impact their mechanical properties. Ensuring the cleanliness of the steel prior to heat treatment can be challenging and may require additional steps such as degreasing, pickling, or using protective atmospheres during heat treatment. Furthermore, some special steels are highly sensitive to overheating, which can lead to grain growth and loss of desired properties. Precise temperature control and monitoring are crucial to prevent overheating and ensure consistent results. Lastly, special steels may have specific time-temperature transformation (TTT) and continuous cooling transformation (CCT) characteristics that need to be considered during heat treatment. Understanding and adhering to the appropriate heating and cooling cycles are essential for achieving the desired microstructure and properties. In summary, the common challenges in heat treating special steel include achieving the desired hardness and microstructure, managing residual stresses, ensuring cleanliness, preventing overheating, and adhering to specific time-temperature transformation characteristics. Overcoming these challenges requires expertise, precise control, and adherence to strict heat treatment protocols.

- Q: How is special steel made?

- Special steel undergoes a complex and precise manufacturing process, consisting of various steps. Initially, high-quality raw materials like iron ore and scrap metal are carefully chosen and then melted in a furnace at extremely high temperatures. This procedure eliminates impurities and forms molten steel. Once the molten steel is obtained, it is further refined to achieve the desired composition and properties. This is accomplished by adding various alloying elements like chromium, nickel, manganese, and vanadium. These elements enhance the steel's strength, hardness, corrosion resistance, and other specific characteristics necessary for the intended application. Following that, the molten steel is cast into different shapes, such as bars, slabs, or billets, using a process called casting. During casting, the steel is poured into molds and allowed to cool and solidify. The resulting solidified steel is then processed further using techniques like rolling, forging, or extrusion to achieve the desired shape and dimensions. After shaping, the steel undergoes heat treatment, which involves controlled heating and cooling processes. Heat treatment refines the steel's microstructure, improving its mechanical properties. This can involve processes like quenching, tempering, annealing, or normalizing, depending on specific requirements. Finally, the steel is subjected to thorough testing and quality control measures to ensure compliance with required specifications and standards. These tests encompass mechanical, chemical, and physical analyses, as well as non-destructive testing techniques, to verify the integrity and performance of the special steel. In summary, the production of special steel is a highly technical and specialized process that entails meticulous selection of raw materials, precise alloying, casting, shaping, heat treatment, and rigorous quality control. The end result is a steel with exceptional properties that can be tailored to meet the specific needs of diverse industries, including automotive, aerospace, construction, or manufacturing.

- Q: How does special steel contribute to the power generation equipment industry?

- Special steel plays a crucial role in the power generation equipment industry by providing exceptional strength, durability, and corrosion resistance. It is extensively used in the manufacturing of turbines, generators, and other critical components, ensuring their reliable performance under extreme conditions. Special steel's high temperature and pressure resistance make it ideal for power plants, enabling efficient energy conversion and minimizing downtime. Additionally, its ability to withstand harsh environments and resist fatigue and wear extends the lifespan of power generation equipment, reducing maintenance costs and enhancing overall productivity in the industry.

- Q: How does special steel contribute to the oil and gas equipment industry?

- Special steel plays a crucial role in the oil and gas equipment industry as it offers exceptional strength, corrosion resistance, and durability. It is used in the manufacturing of various critical components such as pipes, valves, fittings, and offshore platforms. Special steel's high heat resistance and ability to withstand extreme pressure and harsh environments make it an ideal choice for oil and gas equipment, ensuring reliability and safety in operations.

- Q: How does special steel contribute to the infrastructure development?

- Special steel contributes to infrastructure development in several ways. Firstly, special steel possesses high strength and durability properties, making it an ideal material for constructing bridges, buildings, and various infrastructure projects. Its strength allows for the creation of lighter and more efficient structures, reducing construction costs and increasing project lifespan. Additionally, special steel is corrosion-resistant, ensuring the longevity and reliability of infrastructure in harsh environments. Moreover, special steel is used in the production of construction equipment and machinery, enabling efficient and effective construction processes. Overall, special steel plays a crucial role in enhancing the safety, resilience, and sustainability of infrastructure development.

- Q: What are the specific requirements for special steel used in the nuclear waste storage industry?

- The nuclear waste storage industry has stringent and critical requirements for special steel to guarantee the safety and long-term viability of storage facilities. These requirements are driven primarily by the need to mitigate risks associated with nuclear waste, such as radiation leakage and corrosion. One key requirement is the need for high strength and durability. Special steel used in nuclear waste storage must possess exceptional mechanical properties to withstand the weight and pressure exerted by waste containers and the surrounding environment. This includes resistance to deformation, fracture, and fatigue, as well as the ability to maintain structural integrity for an extended period. Another essential requirement is excellent corrosion resistance. Nuclear waste contains highly corrosive substances that can degrade regular steel over time. Therefore, special steel used in the nuclear waste storage industry must have enhanced corrosion resistance to ensure long-term durability and prevent leakage of radioactive materials. Furthermore, the steel must have a low susceptibility to stress corrosion cracking (SCC). SCC occurs when a combination of tensile stress, corrosive environment, and specific material conditions result in crack initiation and propagation. To maintain the integrity of containers and minimize the risk of leakage, the steel used must be highly resistant to SCC. Radiation resistance is also critical for special steel used in nuclear waste storage. The steel should exhibit minimal degradation or embrittlement when exposed to high levels of radiation. This is necessary to maintain the structural integrity of storage containers and prevent any weakening that could compromise waste containment. In addition, the special steel used in the nuclear waste storage industry must comply with strict regulatory standards and certifications. It must meet specific design codes and guidelines set by regulatory authorities to ensure compliance with safety regulations and minimize potential hazards. In conclusion, the special steel used in the nuclear waste storage industry must meet specific requirements, including high strength, durability, corrosion resistance, low susceptibility to stress corrosion cracking, radiation resistance, and compliance with regulatory standards. These requirements are essential for maintaining the safety and integrity of storage facilities and preventing any leakage or release of radioactive materials into the environment.

- Q: How is special steel used in the construction industry?

- Special steel is used in the construction industry for various applications due to its exceptional strength, durability, and resistance to corrosion. It is commonly used for manufacturing structural components, such as beams, columns, and girders, that require high load-bearing capacities. Special steel is also utilized in the construction of bridges, towers, and high-rise buildings to ensure structural integrity and safety. Additionally, it finds application in reinforcing concrete structures, creating strong and long-lasting foundations. Overall, special steel plays a crucial role in enhancing the strength and stability of construction projects.

- Q: Can special steel be used in the pharmaceutical manufacturing industry?

- Yes, special steel can be used in the pharmaceutical manufacturing industry. Special steel is often chosen for its high corrosion resistance, hygiene, and cleanability properties. It is commonly used in the production of pharmaceutical equipment such as tanks, vessels, valves, and piping systems to ensure the quality and safety of pharmaceutical products.

Send your message to us

Grade A36 SS400 Hot Rolled Steel Coil _HR Coil for Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords