40Cr / 41Cr4 / 5140 alloy steel specifications

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

40Cr / 41Cr4 / 5140 alloy steel specifications

Product Description:

1. Standards

GB 40Cr, 40X, ASTM 5140, BS 520M40, JIS SCR440, NF 42C4, DIN 41Cr4(1.7035)

2. Size:

Round steel bar: Dia. 8-10000mm

Flat steel bar: 10-600*205*1500mm

Length: <12m

3. Machine Capability

Tensile strength (N/mm2Mpa): >=835

Elongation %: >=10

Yield strength: >=540

Hardness: HBS<=179

Reduction of area: >=40%

4. Machinability

Long, gummy chips characterize this alloys machinability. It can be machined in the annealed condition, however condition H1150M will yield best results. Post machining solution treatment of parts will be required prior to final hardening if machining in this condition.

5. Welding

Successfully welded by common fusion and resistance methods, this alloy should not be joined by oxyacetylene welding. AWS E/ER630 filler metal is recommended if required.

6. Process:

EAF+LF+VD+ Forged+ Heat Treatment (Annealed, A Normalized, Q+T)

7. Inspection

100% Ultrasonic according to the test standards: SEP1921-84, GR. 3 CLASS C/C

Chemical Composition:

Chemical Composition(for reference only) (%) | |||||||

C | Si | Mn | Cr | Ni | P | S | Cu |

0.37~0.44 | 0.17~0.37 | 0.50~0.80 | 0.8~1.1 | ≤ 0.03 | ≤ 0.035 | ≤ 0.035 | ≤ 0.30 |

Application:

(1) Generally used for producing the important parts with high strength and good plastic.

(2) After nitrogen treatment, used for producing the important parts with special performance

requirements, such as shafts, gears, fasteners, bolt of large dia steamer etc.

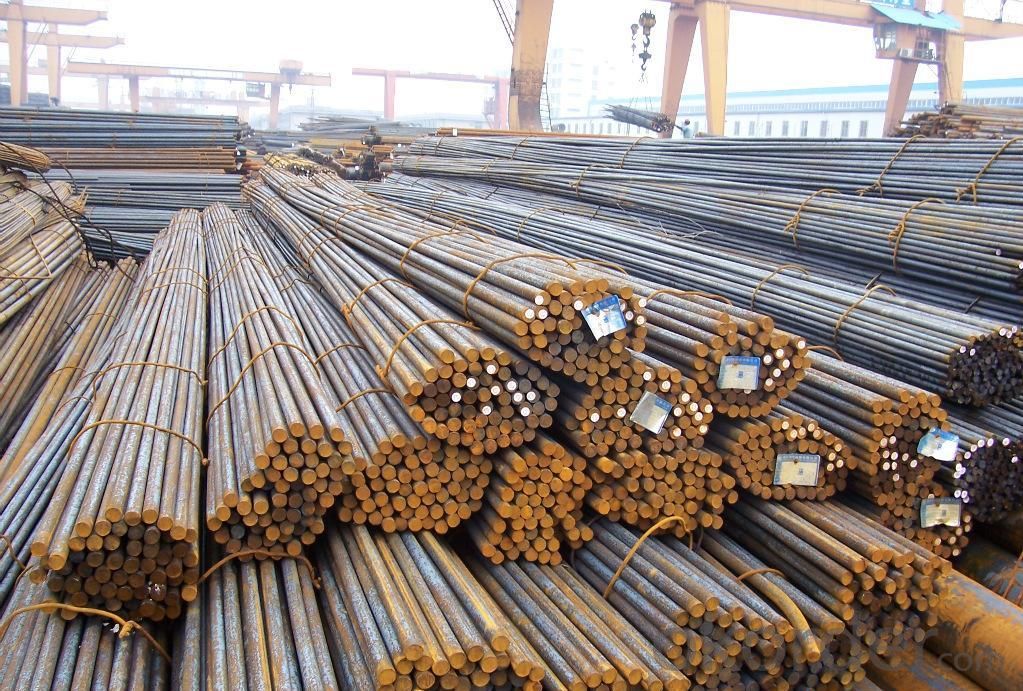

Product Show:

- Q: How is special steel tested for quality?

- Special steel is tested for quality through a series of rigorous examinations and tests. These include visual inspections, chemical composition analysis, mechanical property testing, and non-destructive testing methods such as ultrasonic testing and magnetic particle testing. These tests ensure that the special steel meets the necessary standards and specifications for its intended use, guaranteeing its quality and performance.

- Q: Can special steel be used in the production of knives and blades?

- Yes, special steel can indeed be used in the production of knives and blades. Special steels, such as stainless steel or high-carbon steel, possess properties like corrosion resistance, hardness, and toughness that make them ideal for manufacturing durable and high-performance knives and blades. These steels are often chosen for their ability to retain sharpness, withstand heavy use, and resist rust, ensuring the longevity and reliability of the knives and blades.

- Q: How does special steel compare to other materials?

- Special steel, known as alloy steel as well, possesses outstanding strength, durability, and resistance to wear and corrosion. When compared to regular steel, aluminum, and plastic, special steel stands out due to its superior mechanical properties. To begin with, special steel offers higher tensile strength and hardness, making it perfect for applications that require heavy-duty performance. Its ability to withstand high pressures and temperatures, as well as resistance to deformation, make it suitable for industries like aerospace, automotive, and construction. Furthermore, special steel has excellent wear resistance, making it suitable for applications that endure friction, abrasion, and impact. This characteristic reduces the need for frequent repairs or replacements, resulting in cost savings and improved efficiency. When it comes to corrosion resistance, special steel surpasses regular steel, which tends to rust when exposed to moisture or aggressive environments. The presence of elements like chromium, nickel, and molybdenum in its composition creates a protective layer on the surface, preventing corrosion and extending the lifespan of the material. Compared to materials like aluminum and plastic, special steel has the advantage of being more robust and less prone to deformation or breakage. While aluminum is lightweight, it lacks the strength and hardness of special steel, limiting its suitability for heavy-duty applications. On the other hand, plastic offers lower strength and durability compared to special steel, making it less appropriate for demanding tasks. Moreover, special steel can be easily machined, fabricated, and welded, allowing for versatile applications across various industries. Its flexibility in terms of shaping and forming makes it the preferred choice in the manufacturing of components and structures. In conclusion, special steel outperforms other materials in terms of strength, durability, wear resistance, corrosion resistance, and versatility. Its exceptional properties make it an essential material in demanding industries where reliability and performance are of utmost importance.

- Q: What are the common grades of special steel?

- The common grades of special steel include stainless steel grades such as 304, 316, and 430, as well as tool steel grades like D2, A2, and O1. Other common grades include high-speed steel (HSS), alloy steel grades like 4140 and 4340, and maraging steel grades such as 250 and 300.

- Q: How does special steel perform at high temperatures?

- Special steel performs exceptionally well at high temperatures due to its unique composition and properties. Unlike regular steel, special steel is specifically designed to withstand extreme heat conditions without losing its strength or structural integrity. It exhibits excellent thermal stability, resistance to oxidation, and maintains its hardness and toughness even at elevated temperatures. This makes special steel an ideal material for various applications that require reliable performance under high-temperature environments, such as in aerospace, power generation, and industrial processes.

- Q: How is special steel used in the packaging industry?

- Special steel is used in the packaging industry for a variety of applications such as manufacturing durable and corrosion-resistant containers, packaging machinery, and tools used in the packaging process. It provides strength, reliability, and longevity, ensuring the safety and protection of products during storage and transportation.

- Q: How does special steel perform in high-temperature strength?

- Special steel, also known as high-temperature steel, is specifically designed to excel in high-temperature strength applications. Unlike standard steels, which may lose their strength and structural integrity at elevated temperatures, special steel retains its mechanical properties even under extreme heat conditions. One of the key reasons behind the exceptional high-temperature strength of special steel is its unique composition. It is typically alloyed with elements such as chromium, nickel, and molybdenum, which significantly enhance its resistance to the effects of thermal expansion, oxidation, and creep. These alloying elements form stable oxides on the surface of the steel, acting as a protective layer that prevents further oxidation and corrosion, thereby maintaining the material's strength and integrity. Moreover, the microstructure of special steel plays a crucial role in its high-temperature performance. Through advanced manufacturing techniques, special steel is engineered to have a fine-grained structure, which improves its resistance to deformation and improves its creep strength. The fine grains also contribute to its ability to retain its mechanical properties at elevated temperatures for prolonged periods. Additionally, special steel undergoes rigorous heat treatment processes, such as quenching and tempering, which further enhance its high-temperature strength. These processes help to refine the microstructure and optimize the mechanical properties of the steel, including its hardness, toughness, and resistance to thermal fatigue. In conclusion, special steel is specifically designed and engineered to excel in high-temperature strength applications. Its unique composition, microstructure, and heat treatment processes contribute to its exceptional resistance to thermal expansion, oxidation, and creep, ensuring that it retains its mechanical properties and structural integrity even under extreme heat conditions.

- Q: What are the applications of special steel in the manufacturing industry?

- Special steel has a wide range of applications in the manufacturing industry, including the production of tools, machinery, and equipment. It is commonly used in sectors such as automotive, aerospace, energy, and construction due to its exceptional strength, durability, and resistance to corrosion. Special steel is also utilized in the manufacturing of components that require high wear resistance, such as gears, bearings, and cutting tools. Its versatility and unique properties make it an essential material in various industrial applications.

- Q: What properties make special steel unique?

- Special steel, also known as alloy steel, possesses unique properties that set it apart from other types of steel. Firstly, special steel is distinguished by its exceptional strength and hardness. It is engineered to have a high resistance to deformation, making it suitable for applications that require robust materials. Whether in construction, automotive, or aerospace industries, special steel provides the necessary durability and reliability. Another remarkable property of special steel is its superior corrosion resistance. By incorporating certain alloying elements such as chromium, nickel, or molybdenum, this type of steel becomes highly resistant to rust and other forms of corrosion. As a result, special steel is often used in marine environments, chemical plants, and oil and gas industries where exposure to harsh conditions is prevalent. Furthermore, special steel demonstrates excellent heat resistance. It can withstand high temperatures without losing its strength or structure, making it suitable for applications in extreme heat environments, such as power generation or furnace components. This property allows special steel to be utilized in critical situations where other materials may fail or degrade. Special steel is also known for its versatility and adaptability. With various alloying elements and heat treatment processes, it can be tailored to meet specific requirements of different industries. This flexibility makes it possible to create specialized alloys with unique properties, such as improved machinability, wear resistance, or enhanced magnetic properties, catering to a wide range of applications. In conclusion, the properties that make special steel unique are its exceptional strength and hardness, superior corrosion resistance, excellent heat resistance, and its versatility in being tailored to specific requirements. These properties make special steel an invaluable material in numerous industries, enabling the development of innovative and reliable products.

- Q: How does special steel perform in cryogenic corrosion resistance?

- Special steels are known for their excellent performance in cryogenic corrosion resistance. When exposed to extremely low temperatures, such as those encountered in cryogenic applications, regular steels tend to become brittle and susceptible to corrosion. However, special steels are specifically designed to withstand these conditions and maintain their mechanical properties and corrosion resistance. The performance of special steels in cryogenic environments is mainly attributed to their composition and microstructure. These steels are typically alloyed with elements such as nickel, molybdenum, and nitrogen, which enhance their resistance to corrosion at low temperatures. Additionally, the microstructure of special steels is carefully controlled, resulting in a fine grain size and homogeneous distribution of alloying elements. This microstructure contributes to the steel's ability to resist corrosion and maintain its mechanical strength even at cryogenic temperatures. Furthermore, special steels undergo rigorous testing to ensure their suitability for cryogenic applications. They are subjected to low-temperature impact tests, which assess their toughness and resistance to brittle fracture. These tests verify that the steel can withstand the stresses and strains imposed by cryogenic conditions without failure. Overall, special steels exhibit excellent cryogenic corrosion resistance due to their unique composition, microstructure, and thorough testing. They are a preferred choice for applications that require reliable performance at extremely low temperatures, such as in the aerospace, energy, and scientific research industries.

Send your message to us

40Cr / 41Cr4 / 5140 alloy steel specifications

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords