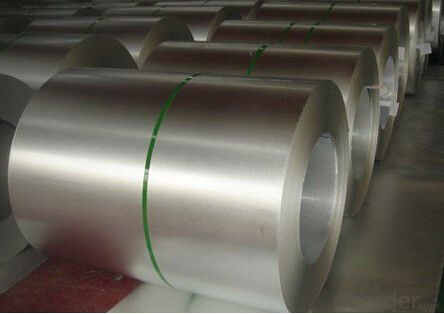

Grade 201 Prime Hot Rolled Cold Rolled Stainless Steel Coils

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Model NO.:201

Type:Stainless Steel Strips

Shape:Round

Grade:200 Series

Certification:ISO, AISI, ASTM, GB, EN, DIN, JIS

Perforated:Not Perforated

Standard:ASTM, AISI, GB, DIN, EN

Technique:Cold Rolled

Surface Treatment:Polished

Width:20-1240mm

Thickness:0.15mm - 2.0mm

Finish:2b, Ba

Export Markets:Global

Additional Info.

Packing:Standard Export Packing

Standard:Grade 201, 430, 410S

Origin:China

HS Code:7220

Production Capacity:30000 Ton Annual

Product Description

201 stainless steel strips or coils:

Cold rolled stainless steel strips or coils

Thickness: 0.15mm to 2.0mm

Width:20mm to 1240 mm

Finish: 2B, BA(two side polishing)

Hot rolled stainless steel strips or coils

Thickness: 2.4mm to 6.0mm

Width:405mm to1520mm

Finish: No.1

Chemical composition:

1) AOD (Low carbon, high nickel) J1 material:

Ni: 1.0-1.5%, Cu:0.8-1.0%, Cr:>13.5%, Mn:9-11%, C:<0.1%

2) AOD (Low carbon, high nickel) J3 material:

Ni: 1.0-1.5%, Cu:0.5-0.8%, Cr:>12%, Mn:9-11%, C:<0.12%

3) Induction (High carbon, low nickel) material:

Ni: 0.6-0.9%, Cu:0.6-0.8%, Cr:>13.0%, Mn:9-11%, C:>0.12%

Application: Making pipes, Utensils, Decoration, Construction, Stamping,Kitchenware, Cookware and so on

Package: standard export packing.

FAQ

1.What's your MOQ?

25MT, it is for one container.

2.Do you have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

3. What's your normal delivery time?

Our delivery time about 10-20days for standard sizes, if you have other requirements like hardness and width ,it is about 20-40days. But don't worry ,we also try our best for the delivery time ,because time longer and our cost is higher.

4.Are the products tested before shipping?

Yes, all of our PPGI and GI was qualified before shipping. We test every batch every day

- Q: How are steel coils used in the production of storage shelves?

- Steel coils are used in the production of storage shelves by being cut and formed into the desired shape and size. These coils are then used to create the framework and support structures of the shelves, providing strength and durability.

- Q: How long can steel coils be stored before they need to be used?

- Steel coils can typically be stored for an extended period of time, ranging from a few months to several years, depending on various factors such as the coating, storage conditions, and the type of steel. However, it is generally recommended to use or sell steel coils within a year or two to ensure their optimal quality and performance.

- Q: I saw an amazing flamenco player, however i have a steel string guitar, where he had a nylon stringed one. So i was wndering if its possible to play flamenco songs on the steel string guitar, and where could i find a tab for it? are there tabs for rasegueados?

- Well, you couldn't play traditional flamenco on a steel string guitar, that's for sure. What you could do is learn some flamenco chords and chord progressions. One problem is that a lot of flamenco techniques on a steel string guitar -- rasgueado, for example -- will literally sand your right hand fingernails down to the nub. It's not going to be pretty, and will probably be painful. Even on a flamenco guitar I protect my right hand nails with a thin coat of super glue. Also, the fingerboard of a flamenco guitar is wider than that of a steel string guitar. That's because many of the notes played in flamenco are actually played with the left hand, not the right hand - lots of hammer ons and pull offs. You can do that higher up the neck on an steel string guitar, but it would be hard to do that in first position on that guitar. Anyway, yes, to a small extent you could conceivably do something that has a flamenco sound on a steel string guitar. But why? You can get a great student model flamenco guitar from Yamaha. It's only $350. Then, you need a teacher. Flamenco is difficult to learn (I've been at it for ten years) and it's important to learn from an instructor who can teach you the correct techniques. Otherwise, you just have to learn everything all over again when you finally do take lessons. Intermediate and advanced students can learn from a video, but beginners really need face time with an instructor. Best wishes.

- Q: How are steel coils inspected for yield strength using tensile testing?

- Steel coils are inspected for yield strength using tensile testing by taking a sample from the coil and subjecting it to a controlled force until it reaches its yield point. The force required to cause permanent deformation in the sample is measured, and this value represents the yield strength of the steel coil.

- Q: this is for a school project due morrow can u please answerwhat are disadvantages of stainless steelplease also show were u got info ty

- Disadvantages of Stainless Steel: 1. High initial cost 2. Difficult to fabricate, or in other words, it is not as malleable as other metals, say iron, and hence if not fabricated properly, results in costly re-work. 3. Difficult to weld 4. High cost of polishing etc. i.e. adding finishing touches for the market. Also, for the record: Stainless steel does NOT rust. One of the advantages of it over other metals (steel and iron) are that it is rust-free. But of course, depending on the environment condition (E.g. long periods in a rainforest without use at all) it can rust....this is a very rare (and unfortunate) situation. ;)

- Q: How are steel coils inspected for thickness using ultrasonic testing?

- Steel coils are inspected for thickness using ultrasonic testing by first preparing the surface of the coil and applying a couplant gel. Then, an ultrasonic transducer is placed on the surface and emits high-frequency sound waves into the coil. These sound waves travel through the material and are reflected back when encountering a change in thickness. The transducer receives these echoes and measures the time it takes for them to return. By analyzing the time delay, the thickness of the steel coil can be accurately determined.

- Q: What are the common coil packaging materials?

- The common coil packaging materials include stretch film, shrink wrap, steel strapping, and wooden or cardboard cradles.

- Q: How do steel coils contribute to the automotive lightweighting trend?

- Steel coils contribute to the automotive lightweighting trend in several ways. First and foremost, steel coils are used in the production of advanced high-strength steels (AHSS) which offer a higher strength-to-weight ratio compared to traditional steel grades. These AHSS can provide the same structural integrity as conventional steel, but with reduced weight. By incorporating AHSS into the construction of vehicle components such as body panels, chassis, and suspension systems, automakers can reduce the overall weight of the vehicle, thus improving fuel efficiency and reducing emissions. Furthermore, steel coils are used in the manufacturing of tailor-rolled blanks (TRBs). TRBs are formed by welding or bonding different steel grades together in a coil before stamping them into the desired shape. This allows for the optimization of material usage, as stronger steel grades can be strategically placed in areas that require higher strength, while lighter grades can be used in less critical areas. This technique not only reduces weight but also enhances safety by reinforcing necessary areas of the vehicle. Moreover, steel coils enable the production of thinner and more formable steel sheets. The advancements in steelmaking technology have allowed for the development of thinner gauges without compromising strength and durability. Thinner steel sheets are easier to shape and form, enabling the creation of complex and lightweight automotive parts. This not only reduces weight but also improves design flexibility and aerodynamics, leading to enhanced performance and fuel efficiency. In addition, steel coils contribute to cost-effectiveness in lightweighting efforts. Steel is a relatively affordable material compared to alternatives like aluminum or carbon fiber. By utilizing steel coils, automakers can achieve lightweighting goals while keeping manufacturing costs under control. This affordability aspect is particularly important in the automotive industry, where cost considerations play a significant role in the design and production of vehicles. In summary, steel coils play a crucial role in the automotive lightweighting trend by enabling the production of advanced high-strength steels, tailor-rolled blanks, thinner and more formable steel sheets, and cost-effective lightweight solutions. These advancements contribute to improved fuel efficiency, reduced emissions, enhanced safety, and increased design flexibility, all of which are key factors in the ever-evolving automotive industry.

- Q: How do steel coils contribute to sound insulation in buildings?

- Steel coils can contribute to sound insulation in buildings due to their high density and ability to absorb and dampen sound waves. The compact arrangement of steel coils within walls or floors helps to reduce the transmission of sound, thus providing a barrier against noise and enhancing the overall acoustic performance of the building.

- Q: How do steel coils contribute to the construction equipment industry?

- Steel coils are essential in the construction equipment industry as they are used to manufacture various components like beams, plates, and tubes. These coils provide the necessary strength and durability needed for constructing heavy machinery and equipment. Additionally, steel coils are also utilized in the fabrication of structural frameworks, reinforcing bars, and other critical parts, ensuring the integrity and safety of construction equipment.

Send your message to us

Grade 201 Prime Hot Rolled Cold Rolled Stainless Steel Coils

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords