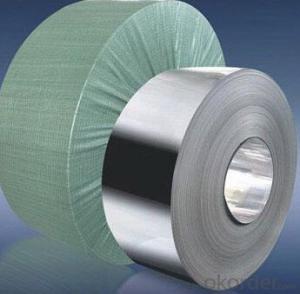

HOT ROLLED STEEL COIL HIGH QUALITY AND COMPETITVE PRICE

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

HOT-ROLLED STEEL COIL

Hot rolled low hardness, easy processing, good ductility.

Available specification:

thickness | width(mm) | length(mm) | coil inside diameter(mm) | |

HOT ROLLED STEEL COIL | 1.5-25 | 600-2000 | 762 | |

HOT ROLLED STEEL STRIP | 1.5-20 | 30-720 | 762 | |

HOT ROLLED STEEL PLATE | 6-700 | 500-4500 | 4000-18000 | |

HOT ROLLED STEELSHEET | 1.2-25 | 50-2000 | 0-18000 |

We can supply customers' with different specifications of the highest quality and lowest price.

With excellent cold bending molded manufacturablity, good decoration effect, strong anti-corrosion ability, galvanized steel coils and sheets are also pollution-free and easily recycled. Accordingly, they can be used as final products and basic plates of color coated steel coils.

Sincerely welcome to contact us for the future details if any item interest you ,and we will make every effort to assure that your requirements will be satisfied ,and we hope to establish long-term business relations with you on the basis of the equality and mutual benefit.

We are waiting for your feedback.

- Q: What are the different types of steel processing techniques for coils?

- There are several different types of steel processing techniques for coils, including hot rolling, cold rolling, galvanizing, and annealing.

- Q: How can I tell the wear resistance, strength, ect from the name of the steel?how could I tell the difference between 420 and 440 steel. what does the HC in 420 HC steel mean? what do the numbers and letters in s30v steel mean?

- So what does all that mean in the real world of knives. 420 has very low carbon by blade standards, as such it is just junk steel. There are three grades of 440, A, B and C. The amount of carbon in A is about half of what C has. (carbon is what makes steel get hard). Iron is very much like a sponge in that it can absorb and hold different alloys. These alloys give the iron different attributes, and they can magnify each other. Like a sponge iron can only hold so much, for Chromium it is around 13%. At that point the steel becomes stainless. The drawback is a loss of strength. As a bladesmith my knives are generally 59 to 60 rch, 420 and 440 at its hardest is 59 but at that it is brittle so most makers draw it down to around 57. In my test a knife made of 420 couldn't make 5 slicing cuts through rope (most couldn't make one). 440 averaged between 5 and 10. Compared to the lowest grade of carbon steel I use (5160) which average between 25 to 30 on the same rope. I have tested many stainless blades and the rule always the same, the more chromium past 13% the weaker the blade and the less edge holding ability.

- Q: I just bought some cheap earrings from this beauty supply store but they said surgical steel So will they prevent my ears from bleeding / infection ?

- Surgical steel is a grade of steel often used in medical appliances like tweezers, forceps, etc. It's generally non-reactive and considered very safe. It doesn't contain any special properties against infection--you still have to observe basic hygiene and clean your piercings properly--but most people can wear surgical steel earrings without a problem. However, if you have a contact allergy to base metals like nickel, surgical steel may cause redness or irritation because of the metals used in it. If cheap rings or necklaces make your skin break out in a rash you should NOT wear surgical steel.

- Q: What are the different types of steel coil loading and unloading methods?

- There are various methods for loading and unloading steel coils, including overhead crane systems, coil lifters, coil hooks, C-hooks, coil tippers, and coil carriages. Each method is suited for different coil sizes, weights, and handling requirements.

- Q: What are the different types of steel coil finishes used in architectural applications?

- There are several different types of steel coil finishes that are commonly used in architectural applications. These finishes are applied to steel coils to enhance their appearance and provide additional protection against corrosion and weathering. Some of the most popular types of steel coil finishes used in architectural applications include: 1. Mill Finish: This is the most basic type of steel coil finish, where the coil is left untreated after being rolled. It has a dull, gray appearance and is often used in industrial and structural applications where aesthetics are not a primary concern. 2. Hot-Dip Galvanized: In this finish, the steel coil is immersed in a bath of molten zinc, which creates a thick layer of zinc coating on the surface. This finish provides excellent corrosion resistance and is commonly used in outdoor architectural applications such as roofing, gutters, and siding. 3. Galvalume: This finish is similar to hot-dip galvanized, but instead of pure zinc, it uses a combination of zinc and aluminum. Galvalume-coated steel coils offer superior corrosion resistance and are often used in high-end architectural applications, such as metal roofing and wall panels. 4. Pre-Painted: In this finish, a layer of paint is applied to the steel coil before it is shipped to the customer. This allows for a wide range of colors and finishes to be achieved, making it a popular choice for architectural applications where aesthetics are important. Pre-painted steel coils are commonly used in exterior cladding, garage doors, and decorative panels. 5. Stainless Steel: This finish is achieved by using a steel alloy that contains a high percentage of chromium. Stainless steel coils have excellent corrosion resistance and are often used in architectural applications where a clean, modern look is desired, such as handrails, elevator interiors, and kitchen appliances. Each type of steel coil finish offers unique advantages and is suitable for different architectural applications. The choice of finish depends on factors such as the desired appearance, level of corrosion resistance required, and the specific environmental conditions the steel will be exposed to.

- Q: At what temperature does steel start to warp or soften.

- It depends upon the composition of steel. Carbon steel, which does not have many alloying elements, softens around 1200C while with alloying elements, this transition temperature either drops or raises depending upon what is added. Higher carbon makes this temperature drop. This is a very important question for forging since if a lower temperature is used, forging won't be easy and at higher than softening temperature, it is not easy to handle. The temperature at which steel begins to soften is, in general, much above what the metallurgists call AC1 or AC3 temperature.

- Q: I have hundreds of pounds of scrap steel... who purchases this steel and what is the price per pound etc. of this? Does someone pick it up or do I bring it somewhere?

- It okorder /

- Q: What processes and materials are used in the production of chrome steel

- well, save up some more $$. I wouldnt feel safe on a $120 mountain bike. My advice would be to invest in something that's a little more money. Also, why do you want a steel frame? Aluminum frames today are made from 7005 alloy, and stack up very well compared to the durability of steel. Plus, they wiegh alot less. Nowadays, youll only find steel on a cheap walmart bike, ir a top notch downhill bike made for extream offf road conditions.

- Q: What are the main properties of steel coils?

- Steel coils possess a multitude of characteristics that render them highly sought-after for a vast array of applications. Primarily, steel coils are renowned for their exceptional robustness and longevity. Boasting a high tensile strength, they exhibit an ability to withstand substantial loads and resist deformation. Consequently, steel coils are the optimum choice for applications that necessitate structural integrity and dependability. Moreover, steel coils exhibit remarkable resistance to corrosion. They possess an inherent capacity to generate a protective oxide layer on their surface, thereby preventing rust and other forms of corrosion. This attribute renders steel coils suitable for applications conducted outdoors or in environments characterized by high humidity or exposure to chemicals. Additionally, steel coils exhibit excellent thermal conductivity, facilitating the efficient transfer of heat. This feature renders them widely employed in heating and cooling systems, as well as in the production of various appliances and machinery. Furthermore, steel coils boast commendable formability, enabling them to be effortlessly shaped or bent into diverse configurations without compromising their strength. This quality endows them with versatility and adaptability, thereby proving indispensable in various manufacturing processes such as stamping, rolling, or welding. Lastly, steel coils are available in an extensive range of grades and thicknesses, allowing for customization based on specific application requirements. This versatility renders steel coils suitable for a vast array of industries, including automotive, construction, manufacturing, and energy. In conclusion, the main attributes of steel coils encompass strength, durability, corrosion resistance, thermal conductivity, formability, and versatility. These characteristics establish steel coils as a popular and dependable choice for a myriad of applications.

- Q: Are steel coils used in the oil and gas industry?

- Yes, steel coils are commonly used in the oil and gas industry for various applications. They are utilized in the manufacturing of pipelines, storage tanks, and other equipment due to their strength, durability, and resistance to corrosion. Steel coils are also employed in the construction of offshore platforms and drilling rigs, where they provide structural support and ensure the safety and reliability of the infrastructure.

Send your message to us

HOT ROLLED STEEL COIL HIGH QUALITY AND COMPETITVE PRICE

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords