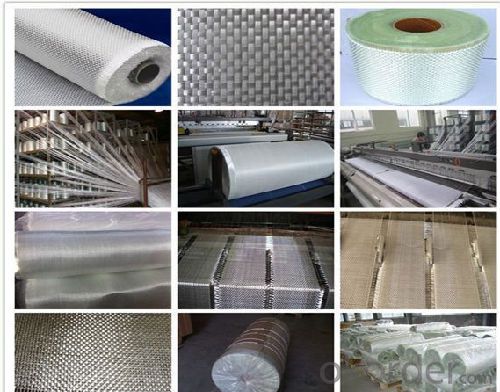

Fiberglass Mat Tissue - Fiber Woven Fabrics with Best Price Good Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000kg kg

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Glass woven rovings are bidirectional fabric by direct rovings in plain weave pattern. They are

applicable for hand lay-up,

winding and compress molding process, suitable for manufacturing tank, boat, automobile parts

and other FRP products.

Main Features :

Main Features :

Consistent thickness and excellent surface treatment.

Rapid impregnating and good compatibility with resin.

Uniform tension, high dimensional stability and making handing easy.

Good mechanical properties and high strength of parts.

ISO9001 certificated

Woven roving Specification:

Normal type | EWR800-1000 | Test Standard |

Apperance | Good | GB/T 18370-2001 |

Density(warpxweft)(end/cm) | 1.8 X 1.5 | GB/T 7689.2-2001 |

Tex (warpxweft) | 2400x2400 | ISO1889 |

Moisture content(%) | ≤0.10 | ISO3344 |

Loss on ignition(%) | 0.40-0.80 | ISO1887 |

Glass | E-glass | N/A |

FAQ :

Delivery Detail: 15-21days

Other spec. can be custom made as per customer's request.

- Q: Can fiberglass mat tissue be used for creating molds?

- Using fiberglass mat tissue for creating molds is not possible. Fiberglass mat tissue is primarily utilized as a reinforcement layer in fiberglass composite applications due to its thin and lightweight nature. It is not intended to be used as a material for making molds. Instead, molds are commonly made using silicone, resin, or plaster, as these materials have the capacity to capture intricate details and offer a polished surface finish.

- Q: Can fiberglass mat tissue be used for acoustic insulation?

- Yes, fiberglass mat tissue can be used for acoustic insulation. It is a commonly used material for soundproofing due to its ability to absorb and dampen sound waves. Its high density and fibrous structure make it effective in reducing noise and improving acoustic performance in buildings, vehicles, and other applications.

- Q: Can fiberglass mat tissue be used for making fiberglass molds?

- Yes, fiberglass mat tissue can be used for making fiberglass molds. It is often used as a reinforcement layer to provide strength and stability to the mold, allowing it to withstand the pressures and forces exerted during the molding process.

- Q: Can fiberglass mat tissue be used for corrosion-resistant coatings?

- Yes, fiberglass mat tissue can be used for corrosion-resistant coatings. It is commonly used as a reinforcing material in composite coatings to enhance their resistance against corrosion and other environmental factors.

- Q: Is fiberglass mat tissue compatible with different resin systems?

- Yes, fiberglass mat tissue is compatible with different resin systems. Fiberglass mat tissue is a versatile material that can be used with various types of resin systems, including polyester, epoxy, and vinyl ester resins. It has excellent wet-out properties, meaning that it can easily absorb and distribute the resin evenly throughout the mat. This compatibility allows for the creation of strong and durable composite structures in a wide range of applications such as automotive, marine, construction, and aerospace industries. However, it is important to consider the specific properties and characteristics of the resin system being used in order to ensure optimal performance and compatibility with the fiberglass mat tissue.

- Q: How does fiberglass mat tissue perform in terms of heat insulation?

- Fiberglass mat tissue performs well in terms of heat insulation due to its low thermal conductivity, which helps to minimize heat transfer. It acts as a barrier, preventing the escape of heat and keeping the surrounding environment insulated.

- Q: Is fiberglass mat tissue fire resistant?

- Yes, fiberglass mat tissue is fire resistant. Fiberglass is made from a combination of glass fibers and resin, which gives it excellent fire-resistant properties. It has a high melting point and does not easily ignite or support combustion. Additionally, fiberglass mat tissue is often treated with fire-resistant coatings or additives to further enhance its fire-resistant capabilities. This makes fiberglass mat tissue a popular choice for various applications where fire resistance is required, such as insulation materials, protective clothing, and fireproof barriers.

- Q: Is fiberglass mat tissue recyclable?

- Yes, fiberglass mat tissue is recyclable.

- Q: Can fiberglass mat tissue be used in marine applications?

- Yes, fiberglass mat tissue can be used in marine applications. It is commonly used in boat building and repair due to its excellent strength, corrosion resistance, and durability in marine environments.

- Q: Can fiberglass mat tissue be used for interior decoration?

- Fiberglass mat tissue is an excellent option for interior decoration. This versatile material serves multiple purposes and is commonly utilized as a reinforcement for composite materials like fiberglass reinforced plastic (FRP). These materials are often employed to create decorative elements such as panels, wall coverings, and moldings. The fiberglass mat tissue offers a lightweight and durable solution with exceptional strength and resistance to moisture and chemicals. Moreover, it can be easily molded into various shapes and designs, making it a favored choice for interior decoration projects. Furthermore, the fiberglass mat tissue can be coated or painted to match any desired color or texture, enabling a wide array of creative possibilities in interior design.

Send your message to us

Fiberglass Mat Tissue - Fiber Woven Fabrics with Best Price Good Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000kg kg

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords