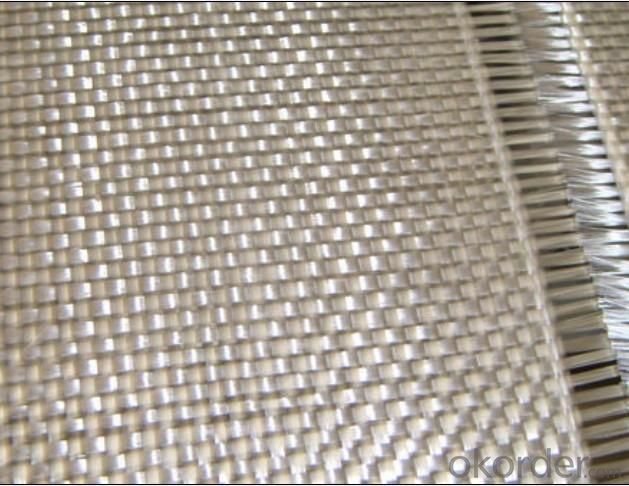

Good Quality Fiberglass Screen Fabric

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 M2 m²

- Supply Capability:

- 50000000 M2 Per Year m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Good Quality Fiberglass fabric:

The Good Quality Fiberglass fabric is weaved of high quality C-glass fibers or E-glass fibers.

The Good Quality Fiberglass fabric is a good construction material with the following excellent properties:

* Dimensional stability

* High Strength

* Fire resistance, High heat resistance

* Good chemical resistance

* Durability

* Forms around complex surface shapes

Application of Good Quality Fiberglass fabric:

Fiberglass fabrics can be used in a variety of applications, including construction in waterproofing applications for roofing and foundation, wall treatment, pipeline joint wrap.

Packing of Good Quality Fiberglass fabric:

Fiberglass fabric is wound on a paper tube with inner diameters of 50. 8, 76 or 152mm. Each roll is wrapped in a plastic bag, then to be packed in a carton box. The rolls are to be horizontally placed.

Width (cm): 90, 100, 127

Length (m): 100, 200, 300, 400

Storage of Good Quality Fiberglass fabric:

Store rolls in a cool, dry location

Protect rolls from weather and other damage.

- Q: Can fiberglass fabric be used for insulation in aerospace applications?

- Certainly, fiberglass fabric has the capability to be utilized for insulation purposes in aerospace settings. Renowned for its exceptional thermal insulation characteristics, fiberglass fabric proves to be an optimal selection for aerospace applications where temperature control is of utmost importance. It possesses traits such as being lightweight and flexible, along with the ability to endure high temperatures, rendering it suitable for deployment in various aerospace components like engine compartments, fuel tanks, and aircraft interiors. Moreover, fiberglass fabric exhibits resistance towards chemicals, moisture, and fire, thereby providing an additional layer of safety and safeguarding in aerospace environments. In conclusion, due to its remarkable thermal properties and durability, fiberglass fabric is a dependable and extensively employed insulation material in aerospace applications.

- Q: What are fiberglass fabrics made of?

- Fiberglass fabrics consist of fibers made from a glass-like substance known as fiberglass. The process involves molding the fiberglass into strands, which are subsequently intertwined to form a textile. Silica, the primary component of fiberglass, is obtained from sand. To improve the fabric's performance, other elements such as limestone, soda ash, and alumina are incorporated into the mixture. These materials are subjected to a procedure called melting and extrusion, in which they are heated to elevated temperatures and then pushed through small apertures to create the slender fibers. Finally, these fibers are interlaced or looped together to produce the ultimate fiberglass fabric, renowned for its robustness, endurance, and resistance to both heat and chemicals.

- Q: Are there any specific installation instructions for fiberglass fabrics?

- Yes, there are specific installation instructions for fiberglass fabrics. When installing fiberglass fabrics, it is important to follow certain steps to ensure proper installation and maximize their effectiveness. Here are some general guidelines to consider: 1. Surface Preparation: Before installing fiberglass fabrics, it is crucial to prepare the surface properly. Ensure that the surface is clean, dry, and free from any debris, dust, or contaminants that might hinder the adhesion of the fabric. 2. Adhesive Selection: Choose an appropriate adhesive that is compatible with fiberglass fabrics and the surface you are working on. Consult the manufacturer's guidelines to select the most suitable adhesive for the specific application. 3. Cutting and Sizing: Measure and cut the fiberglass fabric according to the desired dimensions, ensuring that it provides ample coverage for the intended area. Use sharp scissors or a utility knife to achieve clean and precise cuts. 4. Application of Adhesive: Apply a thin and even layer of the chosen adhesive onto the prepared surface using a brush, roller, or a trowel. Make sure to follow the manufacturer's instructions regarding the adhesive application and drying times. 5. Placement of Fiberglass Fabric: Carefully place the cut fiberglass fabric onto the adhesive-coated surface. Avoid stretching or wrinkling the fabric during installation. Gently smooth out any air bubbles or creases using a roller or a squeegee, ensuring proper adhesion. 6. Additional Layers: If necessary, apply additional layers of fiberglass fabric, overlapping the edges by a few inches to ensure a seamless and durable installation. Follow the same procedure for each layer, applying adhesive and smoothing out any imperfections. 7. Curing Time: Allow sufficient time for the adhesive to cure and the fiberglass fabric to bond securely to the surface. The curing time may vary depending on the type of adhesive used and environmental conditions. Refer to the manufacturer's instructions for the recommended curing time. 8. Finishing Touches: Once the adhesive has fully cured, trim any excess fiberglass fabric using a sharp utility knife. Sand down any rough edges or uneven surfaces for a smooth finish. Remember to always consult the manufacturer's instructions specific to the fiberglass fabric and adhesive you are using, as different products may have unique installation requirements. Additionally, if you are unsure or uncomfortable with the installation process, it is recommended to seek professional assistance to ensure a successful and safe installation.

- Q: How is fiberglass fabric used in the insulation industry?

- Fiberglass fabric is commonly used in the insulation industry as it provides excellent thermal insulation properties. It is often used as a covering material for insulation materials like fiberglass wool or foam to enhance their thermal performance. The fabric acts as a barrier, preventing heat transfer and reducing energy loss. Additionally, it also provides strength and durability to the insulation system, making it widely used in various applications such as residential and commercial buildings, industrial equipment, and automotive insulation.

- Q: What are the different thickness options for fiberglass fabric rolls?

- Fiberglass fabric rolls come in a variety of thickness options to suit different applications and requirements. The thickness of fiberglass fabric is typically measured in ounces per square yard (oz/yd²) or grams per square meter (g/m²). The most common thickness options for fiberglass fabric rolls range from 4 oz/yd² (135 g/m²) to 10 oz/yd² (340 g/m²). These mid-range options are suitable for a wide range of general-purpose applications, such as reinforcing composite materials, boat building, automotive repairs, and insulation. For lighter applications, there are thinner fiberglass fabric rolls available, usually ranging from 1 oz/yd² (34 g/m²) to 3 oz/yd² (102 g/m²). These lightweight options are commonly used for applications where weight is a concern, such as in the aerospace industry, model-making, and hobbyist projects. On the other hand, for more heavy-duty applications that require greater strength and durability, thicker fiberglass fabric rolls are available. These options typically range from 12 oz/yd² (408 g/m²) to 30 oz/yd² (1017 g/m²) or even higher. These thicker fiberglass fabrics are commonly used in industrial settings, such as for reinforcing concrete, manufacturing pipes, tanks, and other structural components. It's important to note that the specific thickness options can vary depending on the manufacturer and supplier. Additionally, some manufacturers may offer custom thickness options to meet specific project requirements. Therefore, it's always advisable to check with the supplier or manufacturer to determine the available thickness options for fiberglass fabric rolls.

- Q: Can fiberglass fabric be used for reinforcement in wind turbine towers?

- Yes, fiberglass fabric can be used for reinforcement in wind turbine towers. It is commonly used due to its high strength-to-weight ratio, durability, and resistance to corrosion. Additionally, fiberglass fabric can be easily molded and formed to suit the specific design requirements of wind turbine towers.

- Q: Can fiberglass fabric be used for making protective sleeves?

- Yes, fiberglass fabric can be used for making protective sleeves. Fiberglass fabric is known for its durability, heat resistance, and ability to withstand high temperatures. These properties make it an excellent choice for protective sleeves, especially in industries where workers are exposed to extreme heat or hazardous materials. Fiberglass fabric can provide a reliable barrier against heat, flames, chemicals, and abrasions, thus protecting the wearer's arms from potential injuries. Additionally, fiberglass fabric is lightweight and flexible, ensuring comfort and ease of movement for the wearer.

- Q: Can fiberglass fabric be used for reinforcement in underground storage tanks?

- Indeed, reinforcement in underground storage tanks can be achieved through the utilization of fiberglass fabric. Renowned for its exceptional corrosion resistance and high strength-to-weight ratio, fiberglass fabric emerges as an optimal selection for this purpose. The incorporation of fiberglass fabric not only enhances the structural integrity of the tank but also mitigates the risk of potential failures or leaks. Additionally, the ease of handling and installation of fiberglass fabric renders it a practical and cost-efficient solution for reinforcing underground storage tanks.

- Q: What's the difference between wall fabric and fiberglass fabric? Which is better for brushing before latex paint? Why?

- Wall fabric prices are more expensive, but the effect is good, suitable for private home improvement

- Q: What is the cost range for fiberglass fabrics?

- The cost range for fiberglass fabrics can vary depending on various factors such as the quality, weight, and width of the fabric, as well as the supplier and any additional features or treatments applied to the fabric. On average, fiberglass fabrics can range from around $5 to $20 per yard. However, higher-end or specialty fiberglass fabrics with specific properties or finishes can be priced higher, with some reaching up to $50 or more per yard. It is important to note that these prices are approximate and may vary based on market conditions and individual suppliers. Additionally, bulk orders or wholesale purchases may offer discounts, so it is recommended to contact suppliers directly for accurate pricing information.

1. Manufacturer Overview

| Location | Zhejiang, China |

| Year Established | 1969 |

| Annual Output Value | Above US$ 150 Million |

| Main Markets | overseas companies in Hongkong, Canada, South Africa, South Korea, India, Italy, Singapore, France and many other countries and regions. |

| Company Certifications | ISO9001;ISO14001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 40%-50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English |

| b) Factory Information | |

| Factory Size: | Above 5000,000 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | |

| Product Price Range | Average |

Send your message to us

Good Quality Fiberglass Screen Fabric

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 M2 m²

- Supply Capability:

- 50000000 M2 Per Year m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords