Gold Aluminum Foil Sheets - 5083 Aluminium Alloy Plate for Marine/Aluminium Cast Plates 5083 5052

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

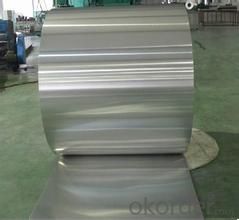

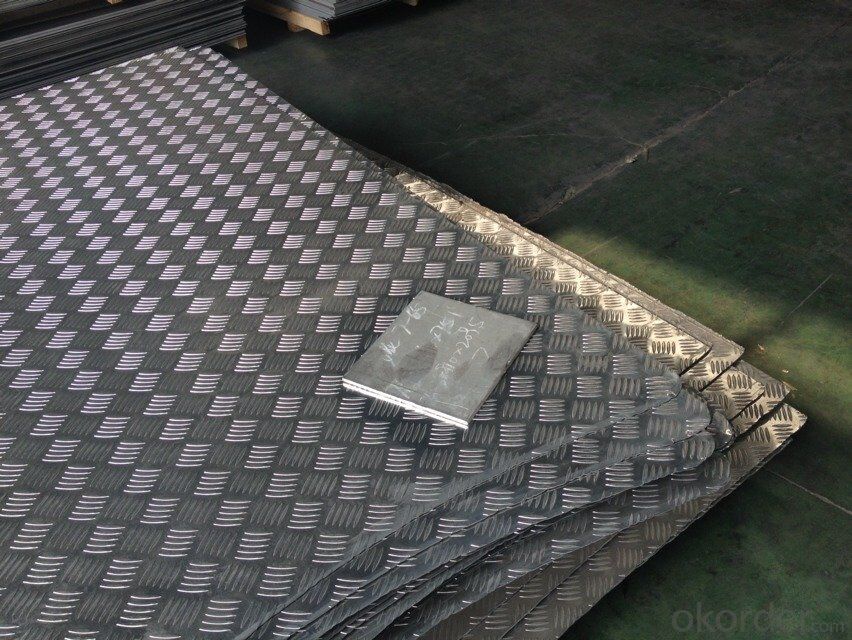

Aluminum Sheet for Making Aluminum Composite Panel

Aluminum sheet specifications:

1) Alloy : 1050 1060 1070 1100 2024 3003 3004 3105 3A21 5005 5052 5083 5754 5182 5454 5456 6061 6063 7075 8011 etc

2) Temper: O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc

3) Thickness: 0.1mm to 300mm

4) Width:20mm to 3300mm

5)Length: ≤ 12000mm

6) Protective film can be added

7) Production Line: DC and CC production line

Discription:

Width: 50-800mm

Thickness: 8-25mic

Length: 3-300m

Character:

High-temperature sterilization

Made of advanced food grade alu material,no pollution

Eco-friendly, recoverable and recyclable

Application:

widely used for food cooking, freezing wrapping, storing etc, the main application are for household and catering, which are targeting for retail market and food service market, such as hypermarket, chain store and hotel, restaurant etc.

Packing:

One roll in an individual box or printed PP bag

Certain quantities in a standard carton

Depends on customer’s request

Service

1. We have the good and professional team, have a good after-sales service.

2. Accept any drawings or your samples to develop new product.

3. Offer relateive technical support,quick response,all your inquire will replied within 24 hours.

4. OEM, buyer design, buyer label services provided.

5. Have the certification of ISO 9001, SGS.

6. Special discount and protection of sales area provided to our distributor.

FAQ

Q1:Do you provide sample? How many days will samples be finished?

Free samples will be provided if needed, but customers should undertake shipping cost or freight charges, samples will be finished in 5-7days

Q2: Can we visit your factory?

Welcome to our factory at any time.

Q3: Complaint solving process

Finding your salesman—Salesman provide you the solution (If it’s our responsibility, we will resend substitutes or return money or provide discount for your next order, etc.; If it’s shipping company’s responsibility, we will also help you until the problem is resolved.) —If salesman can’t solve your problem, please call our manager .

Q4: Delivery time

3~30working days after confirming the payment. If the order is urgent, we will push our workers to finish in advance.

Q5: What's your MOQ?

Normally 8MT are requested as the minium order quantity ,we shall give

additional instructions in special circumstances.

Q6: What are the terms of payment and currencies do you accept?

T/T or L/C is accepted, currently we appreciated your payment through

USD,EUR, RMB

Q7: Do you accept customized orders?

Yes, we do. Your customized orders are always welcomed. Please kindly offer us your samples or drawings, so that we can customize the products according to your preferences. About any further detail, please feel free to contact us.

Q8: What information should I let you know if I want to get a quotation?

Your detailed requirements regarding the products's dimensions, including shape, thickness, top out (length*width*height), and your order quantity are highly appreciated if you want further information about our quotation

Q9: How about the mass production?

The lead time of mass production depend on quantity, usually 25-30days (20FT) .

- Q: How does the surface finish of aluminum sheet affect its cleaning requirements?

- The cleaning requirements of aluminum sheet are significantly influenced by its surface finish. Various surface finishes, such as mill finish, brushed finish, or anodized finish, can impact how dirt, grime, and other contaminants adhere to the surface. Smooth and polished surface finishes like brushed or anodized are generally more resistant to dirt and stains, making them simpler to clean. These finishes have a lower surface roughness, resulting in fewer areas for dirt particles to stick to. As a result, they can be effectively cleaned using gentle cleaning solutions or even just water and a soft cloth. Conversely, aluminum sheets with a mill finish or a rougher surface may require more rigorous cleaning methods. The higher surface roughness of these finishes can create more areas for dirt and grime to become trapped, making it more difficult to remove them with basic cleaning techniques. In such cases, more aggressive cleaning solutions or abrasive cleaning tools may be necessary to eliminate stubborn stains or dirt particles. It should be noted that the specific cleaning requirements for aluminum sheet also depend on the type and severity of the contaminants present. For example, if the aluminum sheet comes into contact with harsh chemicals or corrosive substances, special cleaning methods may be needed to ensure complete removal and prevent any potential damage. In conclusion, the surface finish of aluminum sheet directly affects the cleaning requirements. Smoother and polished finishes are generally easier to clean due to their lower surface roughness, while rougher finishes may require more rigorous cleaning methods. Understanding the surface finish of aluminum sheet is crucial in determining the most suitable cleaning techniques to maintain its appearance and functionality.

- Q: Is it feasible to recycle aluminum profiles after their use?

- <p>Yes, aluminum profiles can be easily recycled after use. Aluminum is one of the most recycled materials in the world due to its durability and recyclability. Recycling aluminum saves energy, as it requires only 5% of the energy needed to produce new aluminum from raw materials. The recycling process is straightforward, involving melting the aluminum, which can then be reformed into new products without losing its properties. This makes aluminum profiles an environmentally friendly choice for many applications.</p>

- Q: Are there any specific storage requirements for 101 aluminum sheets?

- Yes, there are specific storage requirements for 101 aluminum sheets. It is important to store them in a dry, clean, and well-ventilated area to prevent any moisture damage or contamination. Additionally, they should be stored in a horizontal position to avoid warping or bending.

- Q: What are the different methods for joining aluminum sheets?

- Depending on the desired outcome and specific application, there are various methods available for joining aluminum sheets. The following are some commonly used techniques: 1. Welding: Different welding techniques, such as Tungsten Inert Gas (TIG) welding, Metal Inert Gas (MIG) welding, and Resistance Spot Welding (RSW), can be employed to weld aluminum sheets. TIG welding is often preferred for thin sheets as it produces a strong and precise joint. MIG welding, on the other hand, is suitable for thicker sheets and allows for faster production rates. RSW involves passing an electric current through the sheets, melting the aluminum at the contact points, and then applying pressure to create a solid joint. 2. Mechanical Fasteners: Bolts, nuts, and screws can be utilized to join aluminum sheets, providing a reliable and sturdy connection. This method allows for easy disassembly if necessary. Rivets are another commonly used mechanical fastening method, where the sheets are secured using a rivet gun that deforms the rivet. 3. Adhesive Bonding: Specialized adhesives designed for aluminum bonding can be used to join sheets together. This method is often chosen for its ability to create a clean and seamless appearance, making it ideal for situations where aesthetics matter. Adhesive bonding also helps distribute stress evenly across the joint, reducing the risk of localized stress concentration. 4. Clinching: Clinching is a cold joining process that involves deforming the aluminum sheets using a punch, creating a mechanical interlock. This method is quick, cost-effective, and does not require additional materials like fasteners or adhesives. 5. Friction Stir Welding (FSW): FSW is a solid-state joining process that utilizes a rotating tool to generate friction between the aluminum sheets. The friction heats the material, making it pliable, and the rotating tool stirs the softened material together to form a solid joint. FSW is particularly suitable for joining thicker aluminum sheets. Each joining method has its own set of advantages and disadvantages. The choice of method depends on factors such as the desired strength, appearance, production rate, and specific requirements of the application.

- Q: On the web page to see more information on the plating aluminum plate, I do not know what is the difference between aluminized and aluminum plating performance?

- Microstructure characteristics of hot dipped aluminized steelHot dip aluminizing steel to achieve the combination of atoms between iron and aluminum by metal bond, close together, as was shown under the microscope, from the outside to the inside with two aluminum film, three aluminum oxide layer, the alloy layer sequentially formed coating. If the coating of carbon steel, the banded structure and base metal contact.Coating thickness: if carbon steel, then the aluminum layer is 0.04-0.07mm alloy layer, the average 0.05mm. However, the thickness of each layer depends on the type of steel, the amount of carbon, and the temperature and time of the dipping. If the parent material is alloy steel, coating and the differences (omitted).

- Q: Is it possible to use aluminum sheets for roofing purposes?

- <p>Yes, aluminum sheets can be used as roofing materials. They are known for their durability, lightweight, and resistance to corrosion. Aluminum is also recyclable and can be coated with various finishes to enhance its appearance and performance. It is a popular choice for both residential and commercial roofing due to its low maintenance requirements and long lifespan.</p>

- Q: Can aluminum sheet be used for food contact applications?

- Yes, aluminum sheet can be used for food contact applications. Aluminum is a widely used material in the food industry due to its excellent properties. It is non-toxic, corrosion-resistant, and has a high thermal conductivity, making it suitable for various food processing and packaging applications. Aluminum sheets can be used to make food containers, trays, and foils, providing a safe and hygienic option for food storage and transportation. Additionally, aluminum is recyclable, making it an environmentally friendly choice for food contact applications.

- Q: Can the aluminum sheets be used in food or beverage processing industries?

- Yes, aluminum sheets can be used in food or beverage processing industries. Aluminum is a non-toxic material, and it is widely used in the food and beverage industry due to its excellent properties. Aluminum sheets are resistant to corrosion, lightweight, and have good thermal conductivity. These properties make them ideal for various applications in food and beverage processing industries, such as food packaging, cooking utensils, storage containers, and beverage cans. Additionally, aluminum is a sustainable material as it can be recycled, which further enhances its suitability for use in these industries.

- Q: What is the typical bend radius for aluminum sheets?

- The typical bend radius for aluminum sheets can vary depending on the thickness of the sheet and the specific alloy being used. However, in general, a typical bend radius for aluminum sheets ranges from 0.8 to 2 times the thickness of the sheet.

- Q: Are 101 aluminum sheets available in different finishes (e.g., brushed, polished)?

- There are different finishes available for 101 aluminum sheets, including brushed and polished. These finishes are obtained using various methods that create distinct textures and appearances on the surface of the sheets. To achieve a brushed finish, the sheet is brushed with an abrasive material, resulting in a pattern of fine lines. This finish is commonly used to give the sheet a matte look. On the other hand, a polished finish is achieved by polishing the sheet to create a high shine. This finish is often chosen to create a smooth and reflective surface. Therefore, depending on the desired aesthetic or functional requirements, one can opt for either a brushed or polished finish for 101 aluminum sheets.

Send your message to us

Gold Aluminum Foil Sheets - 5083 Aluminium Alloy Plate for Marine/Aluminium Cast Plates 5083 5052

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords