Glassfiber Geogrid, 50-50kn, 100-100kn, 100-200kn/m, high way reinforced grid

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Geogrid:

1) Tensile strength : 20kn-800kn

2) width: Within 6 m

3) length : 50-100m/roll (at request)

4) Material: PP / PET /Fiberglass/ Plastic

5) Color: Black , white ,

6) Certification: CE/ISO9001,14001

7) Manufacturing method: Uniaxial / Biaxial / Wrap Knitting

Applications of Geogrid:

Make reinforce treatment for various kinds of soft soil foundation to evenly distribute load stress and reduce uneven settlement, not easy to generate static electricity, and flammability property good in the coal mine. It is easy to wash coal.

Used in highway, railway, port, airport and municipal project. Support in the recovery working face of coal mine and roadway in the coal mine.

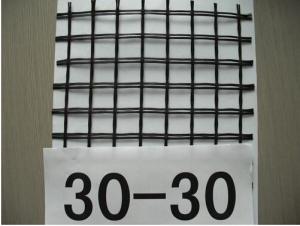

Index Properties | Test Method | Unit | GG1515 | GG2020 | GG3030 | GG4040 |

MD TD | MD TD | MD TD | MD TD | |||

Polymer | -- | -- | PP | PP | PP | PP |

Minimum Carbon Black | ASTM D 4218 | % | 2 | 2 | 2 | 2 |

Tensile Strength@ 2% Strain | ASTM D 6637 | Kn/m | 5 5 | 7 7 | 10.5 10.5 | 14 14 |

Tensile Strength@ 5% Strain | ASTM D 6637 | Kn/m | 7 7 | 14 14 | 21 21 | 28 28 |

Ultimate Tensile Strength | ASTM D 6637 | Kn/m | 15 15 | 20 20 | 30 30 | 40 40 |

Strain @ Ultimate Strength | ASTM D 6637 | % | 13 10 | 13 10 | 13 10 | 13 10 |

Structural Integrity | ||||||

Junction Efficiency | GRI GG2 | % | 93 | 93 | 93 | 93 |

Flexural Rigidity | ASTM D 1388 | Mg-cm | 700000 | 1000000 | 3500000 | 10000000 |

Aperture Stability | COE Method | mm-N/deg | 646 | 707 | 1432 | 2104 |

Dimensions | ||||||

Roll Width | -- | M | 3.95 | 3.95 | 3.95 | 3.95 |

Roll Length | -- | M | 50 | 50 | 50 | 50 |

Roll Weight | -- | Kg | 39 | 50 | 72 | 105 |

MD denotes Machine direction. TD denotes transverse direction. | ||||||

Property of Geogrid:

1.) Improve roadbed bearing capacity,enlarge road lifetime.

2.) Prevent road collapse and crack

3.) Prevent soil and water loss in slope

4.) Could replace steel-plastic geogrid in coal mine.

FAQ:

1. How to order your geogrid ?

a). Tensile strength in warp & weft direction

b). Grid size

c). Width and length

d). Quantity

2. Payment term .

a) TT

b) LC AT SIGHT

c) cash

d) 30% contact value as deposit ,the blance 70% be paid after received the copy of bl .

3. Delivery time

a) 19-25 days after received your depsit .

4. What is MQQ ?

a) 2500 m2 as MQQ , we can also produce sample for you .

Geogrid Show:

- Q: Are geogrids suitable for use in seismic zones?

- Yes, geogrids are suitable for use in seismic zones. Geogrids are flexible and durable materials that can reinforce soil and improve its stability. In seismic zones, where the ground is prone to shaking and instability during earthquakes, geogrids can effectively enhance soil resistance to lateral movement, reduce soil liquefaction, and provide greater overall stability to structures. Their ability to distribute loads and increase soil confinement makes them highly suitable for use in seismic zones.

- Q: Do geogrids affect the permeability of soil?

- Yes, geogrids can affect the permeability of soil. Geogrids are typically used to reinforce soil and improve its stability. They create a barrier that prevents soil particles from shifting, which can reduce the permeability of the soil. However, geogrids can also enhance the drainage properties of soil by providing channels for water to flow through, thereby potentially increasing its permeability in certain cases.

- Q: Are geogrids resistant to microbial attack?

- Yes, geogrids are generally resistant to microbial attack. Their construction materials, such as polyester or polypropylene, are not easily degraded by microorganisms, making geogrids a durable and long-lasting solution in various applications.

- Q: How do geogrids enhance the stability of steep slopes?

- Geogrids enhance the stability of steep slopes by providing reinforcement and increasing the soil's shear resistance. They act as a barrier, distributing the applied loads and reducing the potential for slope failure. Additionally, geogrids improve slope drainage, preventing the accumulation of excess water that can lead to soil erosion and instability.

- Q: Do geogrids provide reinforcement to geosynthetic asphalt liners in reservoirs?

- No, geogrids do not provide reinforcement to geosynthetic asphalt liners in reservoirs.

- Q: And specification.. Thank you for answering me

- There is no relevant national standards and industry standards, where the model

- Q: Can geogrids be used in reinforcement of embankments on collapsible soils?

- Yes, geogrids can be used in the reinforcement of embankments on collapsible soils. Geogrids provide additional stability and strength to the embankment, helping to prevent soil collapse and reduce potential settlement. By distributing loads more evenly, geogrids can effectively reinforce the embankment and improve its overall performance on collapsible soils.

- Q: How many Chinese geogrid manufacturers? How many famous

- Manufacturers have more than N, there is no specific how much to say

- Q: What is the road geogrid

- GeogridThe grid is made of polypropylene, polyvinyl chloride and other high molecular polymer thermoplastic or molded into a two-dimensional grid or a certain degree of three-dimensional grid screen, when used as civil engineering, known as the geogrid

- Q: What are some common standards and specifications for geogrids?

- Some common standards and specifications for geogrids include ASTM D6637, which provides testing methods for determining the tensile properties of geogrids, and ASTM D5262, which specifies the requirements for geogrids used in soil stabilization applications. Additionally, ISO 10318 and EN 15381 are international standards that outline the design, testing, and performance characteristics of geogrids for various applications. These standards ensure that geogrids meet specific criteria for strength, durability, and performance, allowing engineers and designers to choose the appropriate geogrid for their specific project requirements.

Send your message to us

Glassfiber Geogrid, 50-50kn, 100-100kn, 100-200kn/m, high way reinforced grid

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords