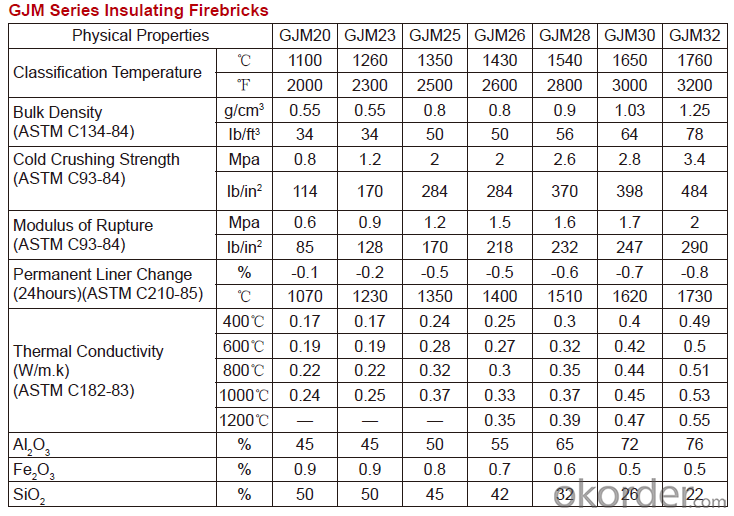

GJM 23 Light Dense Mullite Insulating Fire Brick

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Thermal Insulation Fire Clay Brick

Refractory brick is a refractory material used in lining furnaces, kilns, fireboxes, and fireplaces.

We provide high quality Refractory Fire Bricks that are used on wide range in the various industries like Cement, Glass and Steel. Refractory Fire Bricks are provided as per the quantity and specifications required by the customers. We provide an extensive range of Refractory Fire Bricks at reasonable prices that depend upon the quantity ordered.

Application

Insulating Fire Brick are used for the lining of converter, alternating current arc furnace, direct Current arc furnace and the ladle slag line, etc.

Company Advantage

(1)Long Insulating Fire Brick manufacture history: 25 years manufacturer

(2)Advanced equipment and good service

(3)Diversification of production standards: ISO ANSI FEPA JIS ASTM

(4)Flexible payment: T/T L/C D/P D/A

(5)Professional marketing team and after-sale service

Insulating Fire Brick main feature:

Equipment

1 unit of Ceramic Abrasive (SG Abrasive) pilot production line

2 units of Compact grain Abrasive pilot production lines

1 unit of high-end coated abrasives (abrasive cloth) production line

3 large flexible crushing and sieving lines for grit production lines

6 units of 5000KVA-10000KVA dumping type electric arc furnaces for Brown Fused Alumina fusion

FAQs

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q: Are insulating fire bricks resistant to thermal stress?

- Insulating fire bricks have the ability to resist thermal stress. These bricks are specifically designed to endure high temperatures and fluctuations without cracking or breaking. They are constructed from refractory materials that possess exceptional thermal insulation properties and can tolerate extreme heat. Insulating fire bricks possess a low thermal conductivity, allowing them to effectively resist heat transfer and maintain their structural integrity even when exposed to rapid temperature changes. They find common applications in kilns, furnaces, and fireplaces, where thermal stress is a major concern. In essence, insulating fire bricks are engineered to offer dependable and long-lasting insulation while enduring the thermal stress associated with high-temperature environments.

- Q: Can insulating fire bricks be used for pizza ovens?

- Indeed, pizza ovens can make use of insulating fire bricks. These bricks have been specifically crafted to endure extreme heat and offer exceptional insulation, positioning them as an optimal selection for pizza ovens. By possessing low thermal conductivity, insulating fire bricks excel at retaining heat for extended durations, guaranteeing that your pizza is evenly and efficiently cooked. Moreover, their lightweight composition allows for effortless handling and installation in a pizza oven. Ultimately, the utilization of insulating fire bricks within a pizza oven can effectively uphold high temperatures, diminish heat loss, and enhance the overall cooking proficiency.

- Q: How do insulating fire bricks compare to ceramic fiber insulation?

- Insulating fire bricks and ceramic fiber insulation are both commonly used in high-temperature applications, but they have different properties and advantages. Insulating fire bricks, also known as refractory bricks, are made from a combination of refractory clay and other materials. They are dense and heavy, providing excellent thermal conductivity and insulation. Insulating fire bricks are known for their durability and ability to withstand high temperatures, making them suitable for use in furnaces, kilns, and other industrial applications. On the other hand, ceramic fiber insulation is made from a lightweight material composed of alumina-silica fibers. This type of insulation is highly flexible and can be easily shaped or molded to fit various applications. Ceramic fiber insulation is known for its excellent thermal insulation properties and low thermal conductivity. It is also resistant to thermal shock and can withstand rapid temperature changes. In terms of insulation performance, both insulating fire bricks and ceramic fiber insulation have their advantages. Insulating fire bricks have higher thermal conductivity, which means they can transfer heat more efficiently. This property makes them ideal for applications that require rapid and uniform heat distribution. Ceramic fiber insulation, on the other hand, has lower thermal conductivity, making it more effective at preventing heat transfer. In terms of installation and maintenance, ceramic fiber insulation is easier to handle due to its lightweight and flexible nature. It can be easily cut and shaped to fit complex surfaces, reducing the need for specialized tools or equipment. Insulating fire bricks, on the other hand, are heavier and more rigid, requiring more effort and precision during installation. Overall, the choice between insulating fire bricks and ceramic fiber insulation depends on the specific requirements of the application. Insulating fire bricks are more suitable for applications that require high thermal conductivity and durability, while ceramic fiber insulation is ideal for applications that require excellent thermal insulation and flexibility.

- Q: Can insulating fire bricks be used in the construction of pottery slab rollers?

- Yes, insulating fire bricks can be used in the construction of pottery slab rollers. These bricks can provide thermal insulation and withstand high temperatures, making them suitable for pottery kilns and other heat-intensive applications like slab rollers.

- Q: Can insulating fire bricks be used in space heating applications?

- Yes, insulating fire bricks can be used in space heating applications. Insulating fire bricks are designed to withstand high temperatures and provide excellent insulation, making them suitable for use in heating systems where retaining heat is important. They can help increase the efficiency of space heating applications by reducing heat loss and ensuring more effective heat transfer.

- Q: Are insulating fire bricks suitable for use in the construction of blast furnaces?

- Yes, insulating fire bricks are suitable for use in the construction of blast furnaces. These bricks have excellent insulating properties, high refractoriness, and thermal shock resistance, making them capable of withstanding the extreme temperatures and rapid temperature changes commonly encountered in blast furnaces. Additionally, their lightweight nature allows for easier installation and reduces the overall weight of the furnace structure.

- Q: Can insulating fire bricks be used in ceramic fiber boards?

- Yes, insulating fire bricks can be used in ceramic fiber boards as they provide thermal insulation and enhance the overall insulation properties of the boards.

- Q: Are insulating fire bricks resistant to gas permeability?

- Yes, insulating fire bricks are resistant to gas permeability. These bricks are designed to have low porosity and high density, which helps to prevent the penetration of gases through their structure. They are made from high-quality refractory materials, such as clay or silica, and are manufactured using a special process to ensure minimal pore size and tight packing. This makes them highly effective in containing gases and preventing their leakage. Insulating fire bricks are commonly used in various high-temperature applications, including furnaces, kilns, and industrial boilers, where gas tightness is essential for efficient and safe operations.

- Q: Can insulating fire bricks be used in chimney construction?

- Indeed, insulating fire bricks have the capability to be utilized in the construction of chimneys. These bricks are specifically designed to possess a low thermal conductivity, which ultimately leads to their effectiveness in minimizing heat transfer. As a result, they prove themselves suitable for chimney construction as they aid in maintaining cooler chimney walls and preventing excessive heat from being transmitted to the surrounding structures. Moreover, apart from their lightweight nature, insulating fire bricks possess commendable insulation properties, thereby making their handling and installation in chimney construction a much simpler task. However, it is imperative to acknowledge that in order to comply with safety regulations and ensure proper chimney construction, it is crucial to utilize insulating fire bricks in conjunction with other fire-resistant materials.

- Q: Can insulating fire bricks be used as a lining for kiln cars?

- Yes, insulating fire bricks can be used as a lining for kiln cars. These bricks are designed to withstand high temperatures and have excellent insulating properties, making them ideal for use in kilns where heat retention is required. Additionally, their lightweight nature makes them suitable for use on kiln cars, which need to be moved frequently.

Send your message to us

GJM 23 Light Dense Mullite Insulating Fire Brick

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords