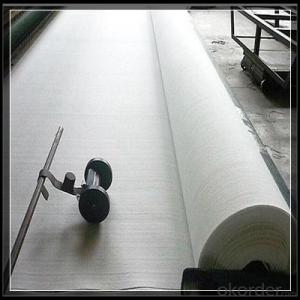

Geotextiles for Erosion Control - High Performance Non-Woven Geotextile Industrial Nonwoven Fabric

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Application

1. Environmental protection, sanitation (such as solid waste landfills, sewage treatment plants, power plants Chi-conditioning, industrial, hospital solid waste, etc.) .

2. Water (such as rivers, lakes and reservoirs of the anti-dam, plugging, reinforcement of the canal seepage, the vertical wall of the heart, slope protection, etc.).

3. Municipal Engineering (subway, on the ground floor of the building, planted roof, the roof garden of anti-seepage, sewage pipes lining, etc.).

4 .Landscape (man-made lake, river, reservoir, golf courses reservoirs of the substrate, slope protection, green lawn of the waterproof moisture, etc.).

5. Petrochemical (chemical plants, oil refineries, gas storage tanks of the anti-chemical reaction tanks, sedimentation tanks of the lining, etc.).

6 Mining (washing and pool heap leaching, the ash-field, dissolved, precipitation, the yard, the tailings seepage substrates, etc.)

Non-woven geotextiles are ideal for use in foundation drainage, behind retaining walls and gabions, in sub-drains, and under rip-rap & armourstone.

Most environmental codes and regulations will require geosynthetic linings for landfill and waste management projects.

Our non-woven geotextile fabrics contain high-grade polypropylene fibres to provide physical strength and excellent fluid management properties.

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: What is the coefficient of friction for nonwoven geotextiles? What is the coefficient of friction between rock and soil?

- Geotextile friction coefficient refers to the friction between the two surfaces and the role of the vertical force on a surface ratio. It is related to the roughness of the surface, regardless of the size of the contact area. According to the nature of motion, it can be divided into dynamic friction coefficient and static friction coefficient.

- Q: Where is the non-woven geotextile in the tunnel?

- The nonwoven geotextile is used to isolate the dome between the concrete and the waterproof layer in the tunnel.

- Q: How are geotextiles affected by moisture content?

- Geotextiles are affected by moisture content in several ways. Firstly, the moisture content can impact the strength and durability of the geotextile material. Excessive moisture can weaken the fabric and reduce its tensile strength, making it less effective in supporting loads or resisting erosion. Additionally, moisture can promote the growth of bacteria and fungi, leading to the deterioration and degradation of the geotextile over time. Furthermore, moisture content can affect the filtration properties of geotextiles, as it can influence the flow of water through the fabric and its ability to retain particles. Therefore, monitoring and controlling moisture levels is crucial to ensure the optimal performance and longevity of geotextiles in various applications.

- Q: Designers give blind ditch length of 540m, geotextile for 2835m2 more

- Too professional. You ask the manufacturers, music built

- Q: Can geotextiles be used in golf course construction?

- Yes, geotextiles can be used in golf course construction. They are often used to provide erosion control, soil stabilization, and drainage solutions in areas such as golf course bunkers, greens, fairways, and tee boxes. Geotextiles can help prevent soil erosion, improve water drainage, and enhance the overall durability and maintenance of golf course surfaces.

- Q: Geomembrane upstream protective layer with what material? The Why can not you use clay?

- With geotextile to do protective layer, because the geotextile and geomembrane as with acid and alkali, is the characteristics of corrosion, the useful life of more than 50 years can better protect the geomembrane. Clay and its performance is far from the comparison, so the use of geotextile hides to avoid waste Zhuan belly over the sand to make the upper reaches of the protective layer. Inquire about Yinjing Li

- Q: Can geotextiles be used in the construction of agricultural ponds?

- Yes, geotextiles can be used in the construction of agricultural ponds. Geotextiles are permeable fabrics that can be used to separate, filter, reinforce, or drain soils in various construction applications. In the case of agricultural ponds, geotextiles can be used to prevent soil erosion, stabilize slopes, and provide protection against punctures or tears in the pond lining. Additionally, geotextiles can help improve water quality by filtering out sediment and contaminants from runoff water entering the pond.

- Q: 300 grams of non-woven geotextile piercing strength is how much

- First of all, according to what you said 300g non-woven geotextile should be polyester staple fiber non-woven geotextile. Polyester staple fiber non - woven geotextile implementation of the national standard GB / T - 2008 standard. According to GB / T-2008 standard anti-puncture strength (standard is CBR burst strength) requirements, 300g national standard geotextile anti-piercing strength should be ≥ 1.5KN.

- Q: Welding geotextile how to apply the mattress on or below

- Geotextile does not need welding, geotextile is geotextile, the product itself exists gaps and pores, in the project mainly play a filter, filter, reinforcement, the role of protection, can not achieve the role of anti-seepage. Generally only need to suture on it. Composite geotextile need to be welded, composite geotextile, also known as composite geomembrane, by the geomembrane through a series of production processes, the upper and lower sides were combined on the geotextile production. In the production process in each roll of composite geotextile of the four sides will be set aside 10-20cm width of the welding edge. Welding construction only need to weld the edge of the geomembrane welding, welding edge of the geotextile suture can be. Geomembrane need to be welded, geomembrane is divided into smooth geomembrane and rough geomembrane (matte geomembrane), smooth geomembrane without the need for direct laying of welding on it. Rough surface geomembrane is generally covered with wool up, welding need to remove the surface and then welding.

- Q: What are the key properties to consider when evaluating geotextiles?

- When evaluating geotextiles, key properties to consider include strength, permeability, durability, and compatibility with the surrounding environment.

Send your message to us

Geotextiles for Erosion Control - High Performance Non-Woven Geotextile Industrial Nonwoven Fabric

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords