Needle Punched Nonwoven Geotextile for Coast Engineering - Geotextiles Soil Erosion Control

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 1500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

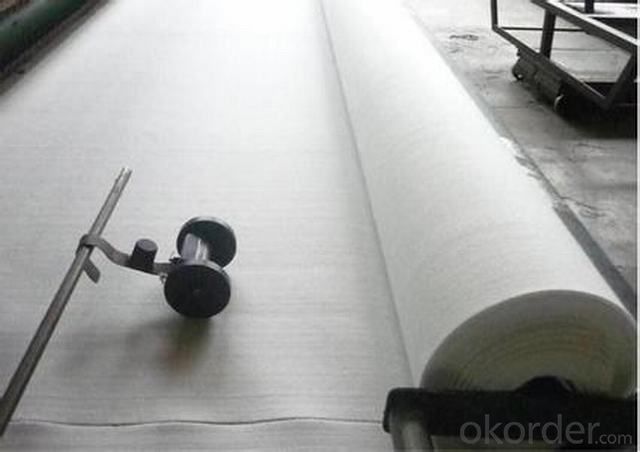

Product Description of Needle Punched Nonwoven Geotextile for Coast Engineering:

1. Specifications

1) Weight / Mass: 100gsm - 1500gsm

2) width: Within 8 m

3) longth: 50-100m/roll (at request)

4) Material: PP / PET

5) Color: Black , white , grey

6) Certification: CE/ISO9001

7) Manufacturing method: nonwoven / woven

2. Features

1) Staple fibers needle punched non woven geotextile

The geotextile is made of polypropylene staple fibers on cross-laying equipment and needle punched equipment. It owns the advantages of acid and alkali resistance, erosion resistance, aging resistance, large strength, stable size, good filtrability etc.

2) Filament non woven geotextile

Filament geotextile has features as follows: High strength, good capacity of elongation and high biology tolerance, alkali tolerance, acidity tolerance, weather resistance good filtration and fine drainage capacity etc. Also it is of low cost, easy in construction and use effects.

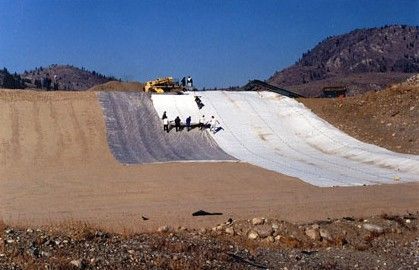

3. Geotextile Applications

1) Filtration :

The filtration layer of the dykes, river canal, seacoast, concrete slope, retaining walls. At the same time of preventing the clay granule from passing, it allows the water and the gas pass through freely.

2) Separation :

The isolation of the railway dregs and the roadbed, roadbed and the soft base, surface of the airdrome and parking lot and the groundsill, different dam materials. It isolates the soil and the gravel of two kinds different granule pathway from the groundsill or other buildings.

3) Adding muscle :

The highway, railway, soil-stone dam, breakwater, airport, backfill soil of retaining wall, slope protection, etc in which distributes the earth stress, prevents the side-displacement of the earth body and improves the earth body stability.

4) Protection :

It prevents the bank from being washed out, protects the bank and the bottom, prevents the water and soil from being washed away.

FAQ:

What is the main application of Needle Punched Nonwoven Geotextile for Coast Engineering?

The main application of our Needle Punched Nonwoven Geotextile for Coast Engineering is as follows: The highway, railway, soil-stone dam, breakwater, airport, backfill soil of retaining wall, slope protection, etc.

Where is your main market?

Our main market is in Middle East, South America and some African countries.

What is your advantages for L Needle Punched Nonwoven Geotextile for Coast Engineering?

One of the largest manufacturer of Needle Punched Nonwoven Geotextile for Coast Engineering with advanced equipment, big production capacity and excellent quality.

- Q: How do geotextiles contribute to groundwater recharge?

- Geotextiles contribute to groundwater recharge by providing a permeable barrier that allows water to infiltrate into the ground while retaining sediment and preventing erosion. This helps to replenish underground aquifers and maintain water levels, ultimately supporting the replenishment of groundwater resources.

- Q: How do geotextiles contribute to the stability of railroad ballast?

- Geotextiles contribute to the stability of railroad ballast by providing reinforcement and separation functions. They help prevent the migration of fine particles from the subgrade into the ballast, which can lead to ballast degradation and loss of stability. Additionally, geotextiles distribute loads evenly, reducing differential settlement and increasing the overall stability of the ballast layer.

- Q: Now geotextile price quota how?

- 2017 geotextile price cheaper than last year, the current price of raw materials is relatively stable production. Geotextile classification of many, you ask more general, so no way to give you a detailed offer. Different technical requirements are uneven prices, but the overall price has come down, and is now the lowest price since 2017.

- Q: What are the key factors affecting the creep behavior of geotextiles?

- There are several key factors that affect the creep behavior of geotextiles. These include the type and quality of the geotextile material, the applied load or stress, the duration of the load, the temperature and moisture conditions, and the installation and maintenance practices. Geotextiles with higher tensile strength and lower elongation properties tend to exhibit less creep. Additionally, higher loads, longer durations, higher temperatures, and elevated moisture levels can all contribute to increased creep in geotextiles. Proper installation and regular maintenance, such as avoiding excessive stretching during installation and minimizing exposure to harsh environmental conditions, can help mitigate creep effects in geotextiles.

- Q: Are geotextiles suitable for use in seismic zones?

- Yes, geotextiles are suitable for use in seismic zones. Geotextiles have been proven to provide effective soil stabilization, erosion control, and reinforcement in areas prone to seismic activity. They can help mitigate soil liquefaction, slope instability, and ground settlement issues, making them a suitable choice for construction projects in seismic zones.

- Q: Geotextile 0.2 and 1.0 which is more sunscreen

- 1.0 more sunscreen

- Q: Are geotextiles resistant to extreme weather conditions?

- Yes, geotextiles are designed to be resistant to extreme weather conditions. They are manufactured using high-quality materials that can withstand harsh weather elements such as heavy rains, strong winds, and intense sunlight. Geotextiles are specifically engineered to provide long-lasting performance and durability even in extreme weather conditions.

- Q: Polyester filament nonwoven is filament geotextile

- Yes, generally do geotextile material, polyester filament nonwoven fabric refers to filament geotextile. Huazhi geotechnical materials manufacturers to answer your questions

- Q: How do geotextiles help in reducing the risk of slope failures?

- Geotextiles help in reducing the risk of slope failures by providing reinforcement and stabilization to unstable slopes. These materials are placed within the slope to increase its strength and prevent erosion. Geotextiles also help in promoting water drainage and filtration, which reduces the build-up of hydrostatic pressure within the slope. Overall, geotextiles enhance the stability of slopes and mitigate the potential for landslides or slope failures.

- Q: What are the different geotextile installation techniques in erosion control?

- Some of the different geotextile installation techniques in erosion control include slope stabilization, sediment control, and shoreline protection. These techniques involve placing geotextile materials in strategic locations to prevent soil erosion, retain sediments, and protect vulnerable areas from wave action.

Send your message to us

Needle Punched Nonwoven Geotextile for Coast Engineering - Geotextiles Soil Erosion Control

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 1500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords