Manas Geotextile for Reinforced Filtration Road

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 1500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

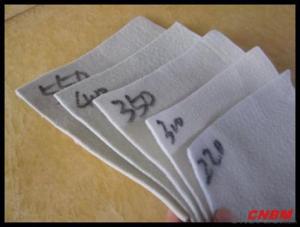

Specifications of Geotextile for Reinforced Filtring Road:

-Reinforced filtering road geotextile

-quality:good quality

-strength:high strength

-tencity:well

-packagel:woven bags

TDS of Geotextile for Reinforced Filtring Road:

NO | Reinforced filtring road geotextile | |

1 | Materaial | Polyester (PET) and polypropylyne(PP) |

2 | Delievery | 7 days after payment |

3 | Package | Woven bags usually, as your requirement |

4 | Color | White,black,gray |

5 | Install | Convinient and safely |

6 | Sale Status | Popular and well selling |

7 | Payment | TT/LC/Western Union,Paypal |

8 | Price | 01-4.0 USD |

9 | After sale service | Professional suggestions and send sample if you want |

- Q: What are the standards and regulations for geotextile products?

- The standards and regulations for geotextile products are set by various organizations such as the American Society for Testing and Materials (ASTM), the International Organization for Standardization (ISO), and the Geosynthetic Institute (GSI). These standards cover different aspects of geotextile products, including their physical properties, mechanical performance, durability, and installation guidelines. Compliance with these standards ensures that geotextile products meet the necessary requirements for their intended applications and ensure the safety and reliability of their use in civil engineering and environmental projects.

- Q: Can the mortar be made directly on the composite geomembrane of the reservoir?

- Yes, as long as there is geotextile can hold mortar I am the production of geotextile materials

- Q: How do geotextiles aid in the reduction of settlement-induced cracking?

- Geotextiles aid in the reduction of settlement-induced cracking by providing a stable and reinforced foundation. These materials are often placed beneath the soil or aggregate layers to distribute loads and prevent differential settlement. By improving the overall stability of the ground, geotextiles help minimize the potential for cracking caused by uneven settlement.

- Q: How do geotextiles contribute to soil reinforcement in embankments?

- Geotextiles contribute to soil reinforcement in embankments by providing strength and stability to the soil. They act as a barrier between the soil layers, preventing their mixing and promoting effective load distribution. Geotextiles also enhance the soil's tensile strength, reducing the risk of erosion and slope failure. Additionally, they improve drainage by allowing water to pass through, reducing pore pressure and maintaining soil stability. Overall, geotextiles play a crucial role in enhancing the performance and durability of embankments by reinforcing the soil and mitigating potential geotechnical issues.

- Q: What is the consequence of the geotextile of the ground floor

- What are the consequences of what can not be finalized, the first roof of the waterproof layer and waterproof protective layer is very important, this is the first barrier, imagine, now many of the green plants are large trees, grow 10 years or even 20 years After the roots will be very developed, think about how the pine trees on the tenacious know their strength, coupled with long-term erosion by the water, the concrete layer will gradually lose its ideal performance, barrier layer and drainage board will certainly be better To protect the role and drainage. So to speak, long-term vision of the words must be solidly do every layer, only focus on economic interests and short-term effects, then, within a few years will not be any problem.

- Q: Are geotextiles suitable for use in geocells?

- Yes, geotextiles are suitable for use in geocells. Geotextiles are often used as a containment system within geocells to prevent soil erosion, reinforce the structure, and improve overall stability. They provide excellent filtration and drainage properties, making them an ideal choice for geocell applications.

- Q: How do geotextiles help with soil reinforcement in soft ground conditions?

- Geotextiles provide soil reinforcement in soft ground conditions by acting as a stabilizing layer. They distribute the load evenly, increasing the soil's bearing capacity and preventing excessive settlement. Additionally, geotextiles enhance soil drainage, reduce water seepage, and prevent erosion, thereby improving the overall stability and strength of the soft ground.

- Q: What are the different geotextile testing parameters?

- There are several different geotextile testing parameters that are used to evaluate the performance and quality of geotextiles. Some of the common parameters include tensile strength, puncture resistance, tear strength, permeability, apparent opening size, and UV resistance. These tests help determine the suitability of geotextiles for specific applications and ensure their durability and effectiveness in various geotechnical and civil engineering projects.

- Q: What are the installation techniques for geotextiles?

- There are several installation techniques for geotextiles, depending on the specific application and requirements. Some common techniques include trenching, anchoring, and overlaying. Trenching involves excavating a trench and placing the geotextile in the desired location, then backfilling the trench with soil or aggregate. Anchoring involves securing the geotextile to the ground using stakes or anchors, providing stability and preventing movement. Overlaying involves placing the geotextile on top of an existing surface, such as a road or landfill, to provide reinforcement and separation. The choice of installation technique depends on factors such as soil conditions, project specifications, and desired results.

- Q: How do geotextiles contribute to soil stabilization in mining areas?

- Geotextiles contribute to soil stabilization in mining areas by providing reinforcement and erosion control. They can be used as a barrier to separate layers of different soil types, preventing mixing and maintaining stability. Geotextiles also help in reducing soil erosion by acting as a filter, allowing water to pass through while retaining fine particles. Additionally, they enhance the load-bearing capacity of the soil, increasing its stability and preventing slope failures.

Send your message to us

Manas Geotextile for Reinforced Filtration Road

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 1500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords