Geotextile Amazon Best Quality Polypropylene Fiberglass Geogrid for Dikes and Dams

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

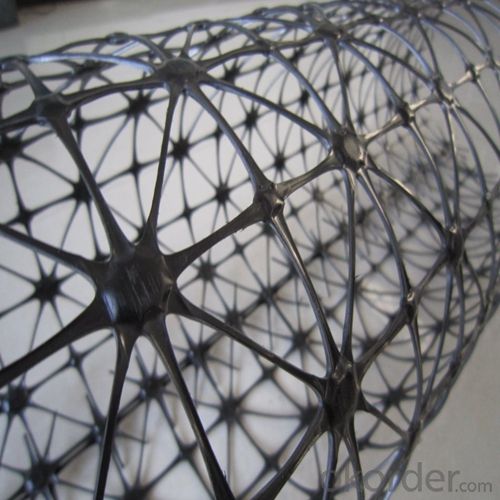

Geogrid allows assembling within the temperature range from -40°C to +60°C. The material is neutral to aggressive environments and ecologically safe. Laying does not require additional machinery. In fold position geogrid does not take much place.

Porducts Description

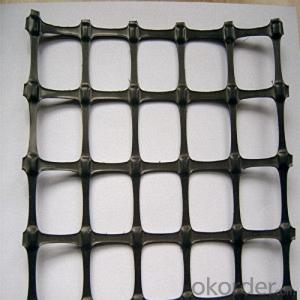

Classify Fiberglass Geogrid Classify Polyester Geogrid

Material Fiberglass Material Polyester

Tensile Strength: 25-25KN; 30-30KN; 50-50KN; 80-80KN; 100-100KN; 120-120KN;

Road Size: 3.95x100m; as customer required;

Application

1. Roadbed reinforcement in highway, railway and municipal road, prevent road surface crack

2. Reinforcement and separation in dam and river, improve soft soil bearing capacity and stability.

Application

1. Roadbed reinforcement in highway, railway and municipal road, prevent road surface crack

2. Reinforcement and separation in dam and river, improve soft soil bearing capacity and stability.

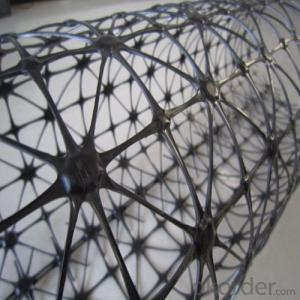

fiberglass geogrid/glass fiber geogrid with CE certificateIntroduction: Fiberglass geogrid is a kind of new favorable earthwork base material to strengthen the road surface and roadbed. This product is composed of fiberglass filaments that are coated with an inorganic sizing agent

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: How do geotextiles improve the performance of geosynthetic tubes?

- Geotextiles improve the performance of geosynthetic tubes by enhancing their filtration and separation capabilities. They act as a barrier against soil particles, preventing clogging and promoting effective water drainage. Additionally, geotextiles provide reinforcement and stabilization to the geosynthetic tubes, increasing their strength and durability. This combination of filtration, separation, and reinforcement properties offered by geotextiles significantly enhances the overall performance of geosynthetic tubes in various geotechnical applications.

- Q: Will you master knitting reinforced geotextile H and reinforced geotextile What is the difference? In addition, how to distinguish between spunbond and weaving in reinforced geotextiles? More

- Texture and material ratio is different ah.

- Q: How to apply geotextile soil

- Directly laying Huazhi geotextile material manufacturers

- Q: Do you have a geotextile

- Summer to sunscreen, winter to antifreeze. The So summer not only to be able to block the sun, but also breathable. The Winter to warm good. The To achieve such a request, no matter what you can make the material. The

- Q: The difference between the construction hdpe impermeable membrane and the geotextile

- Hello, this is two different products Geotextile is not seepage, but the role of filtered water HDPE geomembrane is waterproof. Huazhi geotechnical materials manufacturers to answer your questions

- Q: Why do you want to set up geotextiles around the bottom and bottom of the ditch? What role? Which predecessors help me explain.

- Why do you want to set up geotextiles around the bottom and bottom of the ditch? What role? Which predecessors help me explain.

- Q: I was just doing anti-seepage film and geotextile clerk do not know how to find this project? add me

- Tender is generally the strength of the enterprise to do, just started to recommend you run the site, do network marketing. Many old clerk to learn with an open mind. I wish you a senior clerk as soon as possible

- Q: What is geotextile? Geotextile is what

- Geotextile, also known as geotextile, it is made of synthetic fiber through acupuncture or woven from the permeability of geosynthetics. Finished cloth for the cloth, the general width of 4-6 meters, the length of 50-100 meters. Geotextile is divided into a woven geotextile and non-woven geotextile. Geotextile has excellent filtration, drainage, isolation, reinforcement, anti-seepage, protection, with light weight, high tensile strength, good permeability, high temperature, anti-freeze, anti-aging, corrosion resistance characteristics. Geotextile is one of the geosynthetics, the application of geosynthetics originated in the fifties of the twentieth century, the domestic geotextile is one of the national eight five plan, China promulgated in 1998, "geosynthetics staple fiber Acupuncture non-woven geotextile "(GB / T-1998) standard, the current geotextile has been widely used in many areas.

- Q: What are the geotextiles?

- Geotextile manufacturers should use geomembrane it

- Q: What are the different geotextile durability testing standards?

- There are several geotextile durability testing standards, including the ASTM D4355-17 for durability of geotextiles by accelerated weathering exposure, ASTM D4751-10 for determining the apparent opening size of a geotextile, ASTM D6768-18 for evaluating the effects of heat on geotextiles, and ISO 10319:2015 for determining the resistance of geotextiles to weathering.

Send your message to us

Geotextile Amazon Best Quality Polypropylene Fiberglass Geogrid for Dikes and Dams

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords