Geotextil Sodimac Polypropylene Non-Woven Geotextile for River Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 1500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Polypropylene Non-woven Geotextile for River Construction:

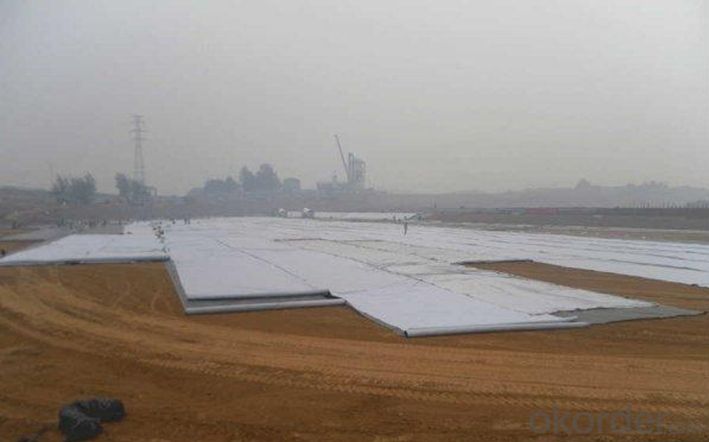

Nonwoven geotextiles are multi-purpose fabrics that are felt-like in appearance. There are numerous practical applications for nonwoven geotextiles. Nonwoven drainage fabrics are an economical alternative to graded aggregate and sand filters and can eliminate many of the problems associated with using, purchasing and transporting aggregate

Features of Polypropylene Non-woven Geotextile for River Construction:

Can withstand the installation stresses

UV stabilized

High chemical resistance

Optimum elongation

Technical Parameters of Polypropylene Non-woven Geotextile for River Construction:

NO. | Item Value | Specification | Note | ||||||||||

| 100 g | 150g | 200g | 250 g | 300 g | 350 g | 400 g | 450 g | 500 g | 600 g | 800 g | ||

1 | Weight Variation% | -8 | -8 | -8 | -8 | -7 | -7 | -7 | -7 | -6 | -6 | -6 | |

2 | Thickness mm≥ | 0.9 | 1.3 | 1.7 | 2.1 | 2.4 | 2.7 | 3.0 | 3.3 | 3.6 | 4.1 | 5.0 | |

3 | Width Variation % | -0.5 | |||||||||||

4 | Breaking Strength KN/m ≥ | 2.5 | 4.5 | 6.5 | 8.0 | 9.5 | 11.0 | 12.5 | 14.0 | 16.0 | 19.0 | 25.0 | MD and TD |

5 | Elongation at Break % | 25~100 | |||||||||||

6 | CBR Mullen Burst Strength KN≥ | 0.3 | 0.6 | 0.9 | 1.2 | 1.5 | 1.8 | 2.1 | 2.4 | 2.7 | 3.2 | 4.0 | |

7 | Sieve Size O90 mm | 0.07~0.2 | | ||||||||||

8 | Vertical Permeability | K× (10-1~10-3) | k=1.0-9.9 | ||||||||||

9 | Tear Strength KN≥ | 0.08 | 0.12 | 0.16 | 0.20 | 0.24 | 0.28 | 0.33 | 0.38 | 0.42 | 0.46 | 0.6 | MD |

FAQ:

What is the main application of Polypropylene Non-woven Geotextile for River Construction?

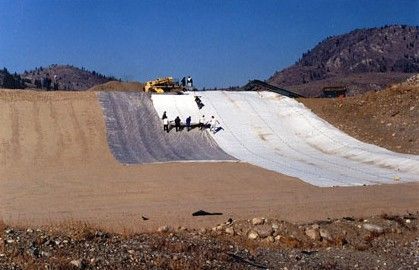

The main application of our Polypropylene Non-woven Geotextile for River Construction is as follows: The highway, railway, soil-stone dam, breakwater, airport, backfill soil of retaining wall, slope protection, etc.

Where is your main market?

Our main market is in Middle East, South America and some African countries.

What is your advantages for PET Continuous Filament Spunbond Needle Punched Nonwoven Geotextile?

One of the largest manufacturer of Polypropylene Non-woven Geotextile for River Construction for Construction with advanced equipment, big production capacity and excellent quality.

- Q: Construction scheme of geotextile water filter

- Second, the design: program one: in strict accordance with the requirements of the national standard construction, 5-year warranty 1, in the smooth level of leveling the overall construction brushing JS waterproof latex or polyurethane waterproof coating, the thickness of the national standard 1 standard; Weak parts to do additional layer to strengthen; 2, do 20 ~ 30mm thick waterproof mortar protective layer, divided into two construction, layer waterproof layer of pulp interface; require nano-silicon waterproofing agent and expansion agent compound use. 3, backfill when asked not to smash the waterproof layer. 4, indoor ground practice ibid, the wall to do high 1m. Option 2: with reference to national standard requirements simple practice, the warranty period of 1 year 1, the overall construction of coated asbestos asphalt waterproof coating or waterproof cold primer, the thickness of the standard by the national standard 2; special weak parts to do additional layer to strengthen; Outside the protection, requiring the use of sticky or sticky sticky construction; 3, backfill when asked not to smash the waterproof layer. 4, indoor ground practice reference program one, the wall to do high 1m.

- Q: Roof geotextile isolation layer sets what the amount

- Polyester filament geotextile Features: Polyester filament geotextile is made by polyester method by spinning acupuncture consolidation directly made, product specifications from 80-800g / m2 arbitrary choice, it is geotechnical engineering and civil engineering In the application of a geosynthetics, polyester filament into a network and consolidation method, the fiber arranged in three-dimensional structure. In addition to good mechanical properties, but also has a good vertical and horizontal drainage performance and good extension properties and high resistance to biological, acid and alkali, anti-aging and other chemical stability. At the same time, it also has a wide pore size range, tortuous pore distribution, excellent permeability and filtration performance. Polyester filament geotextile Uses: water conservancy project dam and slope protection of the filter, channel isolation, seepage; road, rail, airport runway foundation isolation, filter, drainage, slope, retaining wall and road reinforcement, Drainage; Port Engineering soft foundation treatment, beach embankment, harbor wharf and breakwater reinforcement, drainage; polyester filament geotextile has been widely used in the field of infrastructure construction, and gradually applied to a wider range of areas.

- Q: What are the environmental impacts of geotextile production?

- The environmental impacts of geotextile production include energy consumption, greenhouse gas emissions, and potential waste generation. The manufacturing process of geotextiles requires significant energy input, often sourced from fossil fuels, leading to the release of greenhouse gases. Additionally, the extraction and processing of raw materials for geotextiles can have adverse effects on ecosystems, including habitat destruction and soil degradation. Waste generation is another concern, as the production process may generate non-recyclable or non-biodegradable waste materials. However, the use of geotextiles in various applications can also have positive environmental impacts, such as reducing soil erosion and promoting sustainable land management practices.

- Q: Geotextile production process

- 1, add polypropylene particles; 2, extrusion continuous fiber filament. Re-stretching and contraction, the fibers cut into short fiber; 3, the fiber is placed in the machine leveling; 4, continue to polymer film. The film is cut into filaments; 5, after stretching again, the filament is wound on the reel. 6, through a variety of independent research and development of the production process, the fiber for acupuncture, followed by thermal bonding. 6, through a variety of independent research and development of the production process, the fiber for acupuncture, followed by thermal bonding. Use this production process to create a geotextile with ultimate strength

- Q: What is the geotextile material?

- Production of geotextile raw materials are: polyester staple fiber, polypropylene staple fiber, polyester filament, PP flat wire and so on

- Q: What are the applications of geotextiles in landscaping?

- Geotextiles have various applications in landscaping, such as erosion control, weed suppression, soil stabilization, drainage improvement, and reinforcement of slopes. They are used in retaining walls, roads, pathways, and other landscape features to enhance their durability and longevity. Geotextiles also aid in preventing soil erosion and promoting healthy plant growth by providing a barrier against weeds and controlling water drainage.

- Q: Can geotextiles be used in coastal erosion control structures?

- Yes, geotextiles can be used in coastal erosion control structures. Geotextiles are permeable fabrics that can be placed directly on the soil surface or embedded within it to enhance erosion control. They can help stabilize coastal slopes, prevent soil movement, and provide protection against wave action and erosion.

- Q: How do geotextiles improve the stability of slopes?

- Geotextiles improve slope stability by providing reinforcement and erosion control. They are placed within the slope to act as a barrier against soil movement, preventing erosion and enhancing the overall stability of the slope. Additionally, geotextiles help to distribute loads more evenly, reducing the potential for slope failure.

- Q: Can geotextiles be used in retaining wall construction?

- Yes, geotextiles can be used in retaining wall construction. They are often used as a reinforcement material to improve the stability and longevity of the wall. Geotextiles can help in preventing soil erosion, providing drainage, and increasing the overall strength of the retaining wall.

- Q: Such as title. The manager asked them to be made into a square meter compound. What materials can be used to bind them live. 502 glue can not be filled Cao Cao 丨 not only check the intestine Lu adhesive can not be used, glue rods can be used, but EVA is transparent after the appearance of poor adhesion. Neighborhoods. More

- EVA has a special bonding material ah vendors did not tell you?

Send your message to us

Geotextil Sodimac Polypropylene Non-Woven Geotextile for River Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 1500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords