Geotextile A1 - River Bank & Road Construction Polypropylene Nonwoven Geotextile

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

River Bank& Road Construction Polypropylene Nonwoven Geotextile

Desciriptions:

Polyester Nonwoven Geotextile Professioal Waterproof Geotextiles. A woven geotextiles is an economical solution for any civil engineering applications.Made from PP (polypropylene) or PET (polyester) short fiber by nonwoven needle punched manufacturing process, it has isolation, filtration, drainage, reinforcement, protection and maintenance etc. function. It separates, stabilizes, and reinforces soils and allows for filtration Woven geotextiles are manufactured by extruding polypropylene film and then slitting the film into individual yarns which are then woven to form the geotextiles.

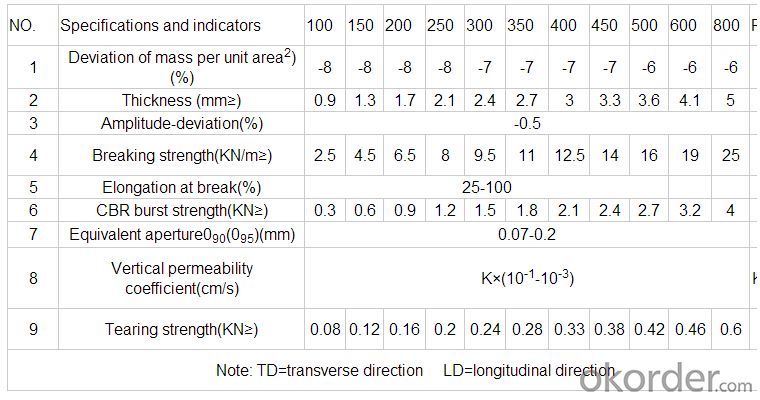

Specifications and Technical datas:

| Weight / Mass | 100gsm - 800gsm |

| width | Within 8 m |

| longth | 50-100m/roll (at request) |

| Material | PP / PET |

| Color | Black , white , grey |

| Certification | CE/ISO9001 |

| Manufacturing method | nonwoven / woven |

Characteristics:

1. Good flexibility, resistant to corrosion, resistant to acids and alkalis, anti-oxidation

2. Separation, filtration, drainage, reinforcement, protection, and maintenance function

Details of our products:

Applications:

1) Filtration :

The filtration layer of the dykes, river canal, seacoast, concrete slope, retaining walls. At the same time of preventing the clay granule from passing, it allows the water and the gas pass through freely.

2) Separation :

The isolation of the railway dregs and the roadbed, roadbed and the soft base, surface of the airdrome and parking lot and the groundsill, different dam materials. It isolates the soil and the gravel of two kinds different granule pathway from the groundsill or other buildings.

3) Adding muscle :

The highway, railway, soil-stone dam, breakwater, airport, backfill soil of retaining wall, slope protection, etc in which distributes the earth stress, prevents the side-displacement of the earth body and improves the earth body stability.

4) Protection :

It prevents the bank from being washed out, protects the bank and the bottom, prevents the water and soil from being washed away.

Packing and shipping:

1. The outer package: black or white woven geotextile.or we can make the package as your requst.

2. Different tgram/ roll size for different qty in the same containers.

3. Roll size: 3.95m*200 for container

FAQ:

Q1: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

Q2:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

HDPE Geomembrane Price

Q3:What is your delivery time?

A:Production time usually costs 2-20 days.

Waiting to cooperate with you!

- Q: What are the different methods of geotextile installation?

- There are several different methods of geotextile installation, including trenching, direct placement, sewing, stapling, and adhesive bonding. Trenching involves excavating a trench and placing the geotextile fabric in it before backfilling. Direct placement involves simply unrolling and placing the geotextile on the desired surface. Sewing involves stitching the geotextile to another fabric or material, providing additional strength. Stapling involves using staples or nails to secure the geotextile to the ground or other surfaces. Adhesive bonding involves using specialized adhesives to attach the geotextile to the desired substrate. The choice of installation method depends on the specific project requirements and the type of geotextile being used.

- Q: Geotextile Commission test how many square meters

- Hello, geotextile cloth sent to the third party testing, the general sampling is one to two squares, on the site supervision sampling sampling, it may also cut a large piece, see the supervision of the Huazhi engineering materials manufacturers for you to answer

- Q: Are geotextiles resistant to abrasion?

- Yes, geotextiles are generally resistant to abrasion. They are designed to withstand rubbing, friction, and wear caused by external forces, making them highly durable and suitable for various applications that involve exposure to abrasive forces.

- Q: What is the high strength to strengthen the composite geotextile

- Bujia Weaving Bugatite Rope

- Q: What are the different types of geotextile seams?

- There are three main types of geotextile seams: butt seams, sewn seams, and heat-sealed seams. Butt seams involve overlapping two geotextile panels and securing them with an adhesive or by heat bonding. Sewn seams involve stitching two panels together using a sewing machine and a high-strength thread. Heat-sealed seams are created by applying heat and pressure to melt the geotextile panels together, creating a strong and durable seam.

- Q: Roof of the geotextile

- Garage, roof green Huazhi geotextile manufacturers, solutions

- Q: What are the factors that affect the strength of geotextiles?

- The strength of geotextiles can be affected by several factors such as the type and quality of materials used, the manufacturing process, the weight and thickness of the geotextile, the presence of any coatings or treatments, and the installation and environmental conditions in which the geotextile is used.

- Q: Geotextile wholesale price of how much money, geotextile fabric manufacturers latest offer

- Geotextile wholesale, ranging from 5000-9000 yuan a ton. Geotextile manufacturers to answer your questions

- Q: U400 geotextile u400 what it means

- Is not 400g / ㎡ of geotextile? My company specializes in the production of geotextiles, details (hand) to see capital (machine) material

- Q: What are the different manufacturing methods for geotextiles?

- There are several different manufacturing methods for geotextiles, including weaving, knitting, and nonwoven processes. Weaving involves interlacing two sets of yarns, warp, and weft, to create a fabric with an ordered structure. Knitting, on the other hand, uses a series of interconnected loops to form a fabric. Nonwoven processes involve bonding fibers together through methods such as needle punching, thermal bonding, or chemical bonding. Each method has its own advantages and is used depending on the specific requirements of the geotextile application.

Send your message to us

Geotextile A1 - River Bank & Road Construction Polypropylene Nonwoven Geotextile

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords