Geogrids Que Son - Bitumen Coated Fiberglass Geogrid with CE Certificate for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 g/m²

- Supply Capability:

- 600000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

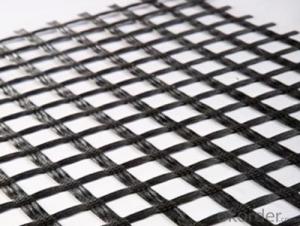

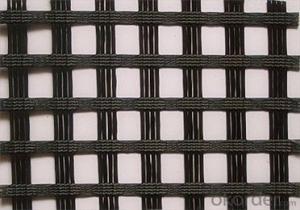

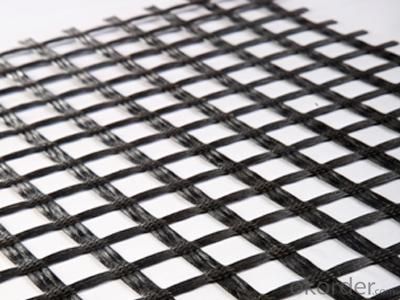

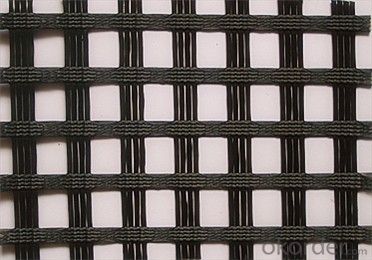

Structure of Bitumen Coated Fiberglass Geogrid Description:

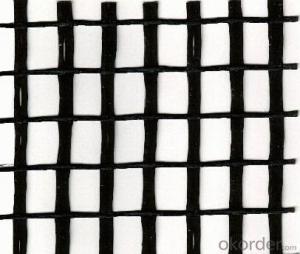

Bitumen Coated Fiberglass Geogrid is a kind of new favorable earthwork base material to strengthen the road surface and roadbed.Used for engineering reinforcement,10%,13% elongation,50x50mm holes size.

Main Features of Bitumen Coated Fiberglass Geogrid:

Improve roadbed bearing capacity,enlarge road lifetime.

Prevent road collapse and crack

Prevent soil and water loss in slope

Could replace steel-plastic geogrid in coal mine.

Bitumen Coated Fiberglass Geogrid Images

Bitumen Coated Fiberglass Geogrid Specification:

| MODEL | GSZ30 | GSZ40 | GSZ50 | GSZ60 | GSZ70 | GSZ80 | GSZ100 | GSZ125 | GSZ150 |

Limit longitudinal tensile | 30 | 40 | 50 | 60 | 70 | 80 | 100 | 125 | 150 |

Limit longitudinal elongation | 3 | ||||||||

Tensile at 2% of stretch | 23 | 29 | 42 | 51 | 59 | 67 | 84 | 107 | 127 |

Solder joint Peel strength N≥ | |||||||||

FAQ

We have organized several common questions for our clients,may help you sincerely:

Q1: How about your company?

A1:Our company are one of the largest geosynthetic products supplier in the world.We have the products experience more than 20 years.Already export to USA/Germeny/Australia/Zambia/Brazil etc.more than 20 countries.Almost 10years.Our products including Geocell/Fiberglass Geogrid/Geomembrane/Geotextile/Geonet etc.

Q2.Does your products have good qualitity?

A2:Yes,we have do many big projects such as the 2008 Beijing Olympic BIRD NEST. Divert water from the south to the north project. And our products have CE certificate also.

Q3:How long can we receive the products after purchase?

A3:In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 15-20 working days can be delivery.

- Q: What are the advantages of using geogrids in construction projects?

- Geogrids offer several advantages in construction projects. Firstly, they provide reinforcement to the soil, enhancing its stability and load-bearing capacity. This allows for the construction of structures on weak or challenging soils that would otherwise require expensive excavation or additional materials. Additionally, geogrids help in preventing soil erosion by providing a barrier against the movement of soil particles, reducing the need for costly erosion control measures. Moreover, these grids are lightweight, making them easy to handle and install, saving time and labor costs during construction. Lastly, geogrids have a long lifespan and are resistant to chemical degradation, ensuring their effectiveness and durability over time. Overall, geogrids offer a cost-effective and sustainable solution for improving the performance and longevity of construction projects.

- Q: Can geogrids be used in mining operations?

- Yes, geogrids can be used in mining operations. Geogrids are commonly used in mining for various purposes such as soil stabilization, reinforcement of embankments, and slope stabilization. They provide strength and stability to the mining site, preventing soil erosion and enhancing safety during mining operations.

- Q: Can geogrids be used in reinforcement of underground stormwater detention systems?

- Yes, geogrids can be used in the reinforcement of underground stormwater detention systems. Geogrids are commonly used to provide stability and enhance the load-bearing capacity of soil and aggregate materials. In the case of underground stormwater detention systems, geogrids can be installed to reinforce the walls and base of the system, preventing soil erosion and maintaining the structural integrity of the system.

- Q: Who knows how much the staggered distance of the lap joint of the geogrid is?

- Straight and smooth and close to the cushion, all longitudinal or transverse lap joints should be staggered, overlapping length shall not be less than 300MM.

- Q: What kind of experiments need to be done to check geogrid

- Review of the general test or the original detection of the project, but the general requirement to double the number of detection. That is, if there is a sample test is not qualified, then the general review is to extract two samples from the original test material to re check.

- Q: What is the minimum net size of geogrid mesh Center

- This depends on the material

- Q: How do geogrids help in reducing the risk of foundation settlement?

- Geogrids help in reducing the risk of foundation settlement by providing additional support and stability to the soil beneath the foundation. They act as a reinforcement material that enhances the load-bearing capacity of the soil, preventing it from shifting or settling. This helps distribute the weight of the structure more evenly, reducing the potential for uneven settlement and potential damage to the foundation.

- Q: The future of geotechnical materials

- Glass fiber geogridGlass fiber geogrid is glass fiber as the material, the reticular structure material of the knitting process, for the protection of glass fiber, improve the overall performance, the highway reinforced material through a special coating treatment process and the.

- Q: In the reinforced earth retaining wall, the geogrid is connected with the panel

- If the precast or cast-in-place concrete panel and the prefabricated block are used as the wall surface, when the utility model is manufactured, the clipping geogrid with transverse ribs is anchored to the block structure. When installed with a connecting rod like a pin. If it is anti wrap form, the lower end of the direct and the upper part of the corresponding part of the link with the connecting rod after the tension, and then fill compacted.

- Q: Can geogrids be used in coastal protection?

- Yes, geogrids can be used in coastal protection. Geogrids are commonly used in various coastal protection measures such as shoreline stabilization, erosion control, and sea defense structures. They provide reinforcement and stability to coastal soil and structures while allowing for proper drainage and vegetation growth. Geogrids help to prevent erosion and mitigate the impacts of waves, tides, and storm surges, making them an effective solution for coastal protection.

Send your message to us

Geogrids Que Son - Bitumen Coated Fiberglass Geogrid with CE Certificate for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 g/m²

- Supply Capability:

- 600000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords