Geogrids Nptel Plastic Biaxial Geogrid for Road Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

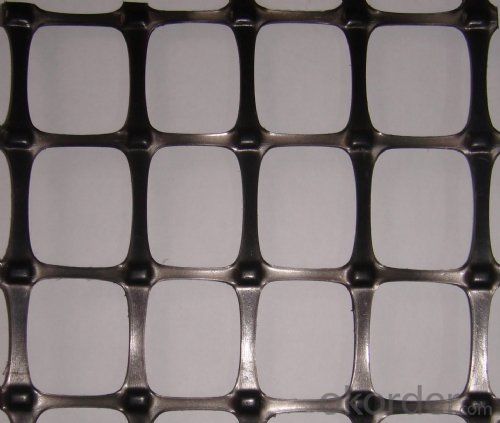

1. Description

Plastic biaxial geogrid with high strength steel wire (or other fiber), through special processing, and polyethylene (PE) or polypropylene (PP), and adding other assistants, by extrusion into composite type high tensile belt, and the surface is rough textured, for high strength reinforced geotextile strips. The single band, the longitudinal, transverse certain space preparation or clamping arrangement, with special reinforcement welding technology welding the connection point bonding and molding, is reinforced with Geogrid.

Make reinforce treatment for various kinds of soft soil foundation to evenly distribute load stress and reduce uneven settlement, not easy to generate static electricity, and flammability property good in the coal mine. It is easy to wash coal.

Used in highway, railway, port, airport and municipal project. Support in the recovery working face of coal mine and roadway in the coal mine.

3. Properties

High stength,small deformation, homogenous stucture, easy for constrution etc.

FAQ:

Q:How about the delivery time?

A:Lead time since receipt of 30% T/T deposit payment: 3 weeks.

Q:What kind of payments does jenor support?

A:T/T, L/C, Cash are accepted.

Q:What's are the MOQ?

A:We can according to your condition to set the MOQ.

And we can provide you samples for quality inspection.

Q:Do you charge for the samples?

A:Accordeing to our company policy, the samples are freee, we only charge the freight fee. And we will return the freight fee If you set the order .

Q:Can you produce the product according to customers' requirements ?

A:Sure, we are professional manufacturer, OEM and ODM are both welcome.

Plastic biaxial geogrid with high strength steel wire (or other fiber), through special processing, and polyethylene (PE) or polypropylene (PP), and adding other assistants, by extrusion into composite type high tensile belt, and the surface is rough textured, for high strength reinforced geotextile strips. The single band, the longitudinal, transverse certain space preparation or clamping arrangement, with special reinforcement welding technology welding the connection point bonding and molding, is reinforced with Geogrid.

Make reinforce treatment for various kinds of soft soil foundation to evenly distribute load stress and reduce uneven settlement, not easy to generate static electricity, and flammability property good in the coal mine. It is easy to wash coal.

Used in highway, railway, port, airport and municipal project. Support in the recovery working face of coal mine and roadway in the coal mine.

3. Properties

High stength,small deformation, homogenous stucture, easy for constrution etc.

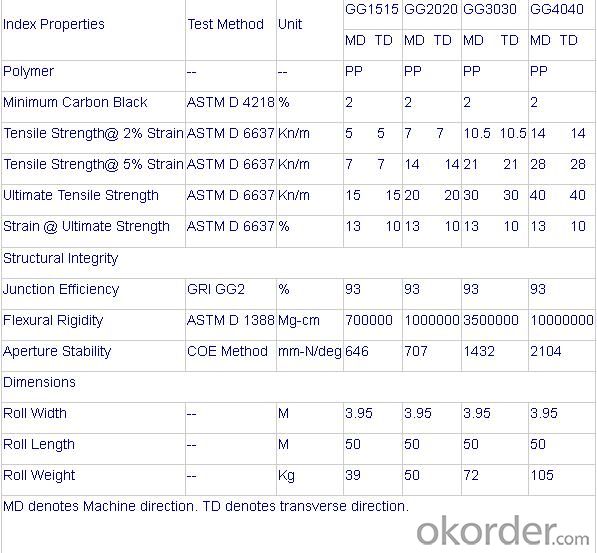

4. Specification

FAQ:

Q:How about the delivery time?

A:Lead time since receipt of 30% T/T deposit payment: 3 weeks.

Q:What kind of payments does jenor support?

A:T/T, L/C, Cash are accepted.

Q:What's are the MOQ?

A:We can according to your condition to set the MOQ.

And we can provide you samples for quality inspection.

Q:Do you charge for the samples?

A:Accordeing to our company policy, the samples are freee, we only charge the freight fee. And we will return the freight fee If you set the order .

Q:Can you produce the product according to customers' requirements ?

A:Sure, we are professional manufacturer, OEM and ODM are both welcome.

- Q: How are geogrids installed in construction projects?

- Geogrids are typically installed in construction projects by first preparing the ground surface and ensuring it is compacted and leveled. The geogrid is then laid out on the prepared surface and secured in place using stakes or anchor systems. It is important to ensure that the geogrid is properly tensioned and aligned to provide maximum stability and reinforcement. Finally, the geogrid is covered with additional layers of soil or other construction materials to complete the installation.

- Q: Do geogrids affect soil drainage?

- Yes, geogrids can affect soil drainage. Geogrids are typically used to reinforce soil and improve its stability. However, their presence can also impact the movement of water through the soil. Depending on the design and installation of the geogrids, they can either enhance or inhibit soil drainage.

- Q: What are the differences between geogrids and geopipes?

- Geogrids and geopipes are both geosynthetic materials used in civil engineering and construction projects, but they serve different purposes. Geogrids are typically made of high-strength polymers or metals and are used to reinforce soil, providing stability and enhancing load-bearing capacity. They are commonly used in applications such as retaining walls, slope stabilization, and road and pavement construction. Geogrids have an open structure with interlocking apertures, allowing soil particles to interlock with the material, creating a strong composite. On the other hand, geopipes are typically made of high-density polyethylene (HDPE) and are used for subsurface drainage and water management systems. They have a perforated or slotted design that allows for the efficient collection and transportation of excess water from the soil. Geopipes are commonly used in applications such as underdrains, French drains, and stormwater management systems. In summary, geogrids are used for soil reinforcement and stability, while geopipes are used for subsurface drainage and water management.

- Q: How are geogrids used in civil engineering?

- Geogrids are used in civil engineering to reinforce soil, stabilize slopes, and strengthen the base of roads and retaining walls. They are typically made of high-strength polymer materials and are installed in layers to provide additional structural support and prevent soil erosion. Geogrids help distribute loads, increase soil stability, and enhance the overall durability and performance of civil engineering structures.

- Q: How do geogrids improve the performance of geosynthetic-reinforced foundations?

- Geogrids improve the performance of geosynthetic-reinforced foundations by providing increased tensile strength and stability to the soil. They act as a reinforcement layer, distributing loads more evenly and reducing the potential for soil settlement or failure. Additionally, geogrids enhance the overall bearing capacity of the foundation, ensuring better long-term performance and reducing the risk of structural damage.

- Q: Are geogrids effective in reducing soil erosion?

- Yes, geogrids are effective in reducing soil erosion. Geogrids provide stabilization and reinforcement to the soil, preventing it from being washed away by water or wind. They act as a barrier, holding the soil in place and reducing the chances of erosion occurring. Additionally, geogrids improve the overall strength and integrity of the soil, making it more resistant to erosion in the long term.

- Q: Are there any specific requirements for geogrid installation in road construction?

- Yes, there are specific requirements for geogrid installation in road construction. These requirements include proper site preparation, ensuring the geogrid is laid flat and taut, adequate overlap and anchoring, and proper compaction of the surrounding soil. Additionally, the geogrid should be installed according to the manufacturer's guidelines and in compliance with relevant industry standards and specifications.

- Q: Can geogrids be used in bridge abutment reinforcement?

- Yes, geogrids can be used in bridge abutment reinforcement. Geogrids are commonly used in civil engineering for soil stabilization and reinforcement. They can provide additional strength and stability to bridge abutments by improving the load-bearing capacity of the soil and preventing settlement or lateral movement.

- Q: Can geogrids be used in ground reinforcement for military installations?

- Yes, geogrids can be used in ground reinforcement for military installations. Geogrids are commonly used to improve soil stability, increase load-bearing capacity, and enhance erosion control. They can effectively reinforce the ground and provide a stable foundation for military infrastructure such as roads, runways, and temporary structures.

- Q: How do geogrids improve the performance of geotextile tubes?

- Geogrids improve the performance of geotextile tubes by providing additional structural support and stability. They enhance the tensile strength of the geotextile tubes, preventing deformation and maintaining their shape under pressure. Geogrids also increase the overall load-bearing capacity of the geotextile tubes, making them more effective in erosion control, shoreline protection, and soil stabilization applications.

Send your message to us

Geogrids Nptel Plastic Biaxial Geogrid for Road Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords