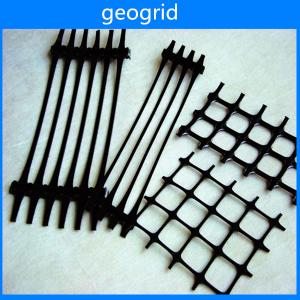

Geogrids and Soil Stabilisation Materials - Most Popular Geogrid in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 50000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Geogrid Introduction:

Fiberglass geogrid is a kind of planar mesh material using alkali-free fiberglass yarn as base body and then coated with high quality modified asphalt. It is warp knitted with oriental structure which gives full play of yarn strength and improves its mechanical property to make the product high tensile, tearing and creep-resistant. Moreover, the composite property of coating with asphalt makes full protection of the fiberglass matrix and greatly improves its wear and shear resistance. All the advantageous functions make the product have a good performance in pavement strengthening, track cracking and solving difficulties of strengthening the bituminous pavement.

Fiberglass Geogrid Features:

1. Light weight, high tensile strength, high modulus, low elongation and good toughness.

2. Corrosion resistance, no long-term creep, long life span.

3. Good physical and chemical stability and good thermal stability.

4. Resistant to fatigue cracking, high-temperature track and low temperature shrinkage cracking.

5. Delaying and decreasing crack reflection.

Specifications | PET20-20 | PET30-30 | PET40-40 | PET50-50 | PET80-80 | PET100-100 | PET120-120 |

Elongation(%) | 10%~15% | ||||||

Vert Tensile strength(KN/m) | 20 | 30 | 40 | 50 | 80 | 100 | 120 |

Horiz Tensile strength(KN/m) | 20 | 30 | 40 | 50 | 80 | 100 | 120 |

Grid(mm) | 12.5×12.5 20×20 24.5×24.5 | ||||||

Width(m) | 1—6 | ||||||

Fiberglass Geogrid Application:

1. Road surface asphalt overlay construction engineering; Asphalt layers

reinforcement.

2. Converting old cement concrete road into composite road; Restraining

reflection cracking caused by block shrinkage.

3. Road extension; Preventing and controlling the cracking caused by new

and old combination and uneven settlement.

4. Treatment of the conjunction between tunnel and bridge or foundation.

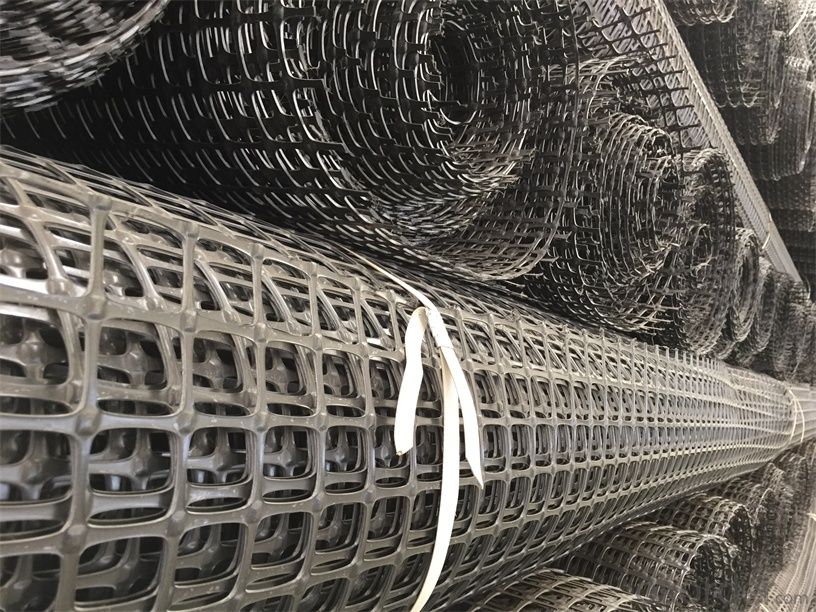

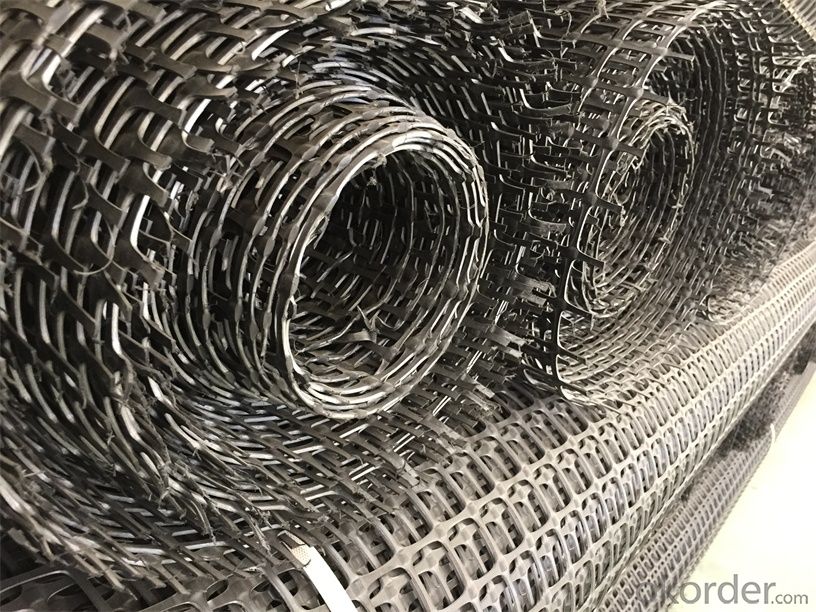

Packaging & Shipping:

FAQ:

1. How to order your geogrid ?

a) Tensile strength in warp & weft direction

b) Grid size

c) Roll Width and length

d) Quantity

2. What is the Payment term?

a) TT

b) LC AT SIGHT

c) cash

d) 30% contact value as deposit ,the blance 70% be paid after received the copy of bl .

3. Delivery time

a) 19-25 days after received your depsit .

4. What is MQQ ?

a) 2500 m2 as MQQ , we can also produce sample for you .

Welcome to send your inquiry to us, and if you have any question, we can also help you.

- Q: What is the effect of moisture on geogrid performance?

- Moisture can have a significant impact on geogrid performance. When geogrids are exposed to moisture, they may experience reduced tensile strength and stiffness, as well as increased elongation and creep deformation. Moisture can also lead to the degradation of geogrid materials, especially if they are not resistant to chemical or biological attack. Additionally, moisture can affect the interaction between geogrids and the surrounding soil, potentially reducing their effectiveness in providing soil reinforcement or confinement. Therefore, it is important to consider and mitigate the effects of moisture when using geogrids in engineering applications.

- Q: What are the different installation methods for geogrids?

- There are several installation methods for geogrids, including direct placement, trenching and backfilling, and mechanical installation. Direct placement involves laying the geogrid directly on the subgrade or soil surface and then covering it with a layer of aggregate. Trenching and backfilling method involves excavating a trench, placing the geogrid in the trench, and then backfilling it with soil or aggregate. Mechanical installation methods use specialized equipment, such as a geogrid installation machine, to unroll and place the geogrid in the desired location. The chosen installation method depends on factors such as the application, site conditions, and specific project requirements.

- Q: Are geogrids suitable for use in green roof systems?

- Yes, geogrids are suitable for use in green roof systems. Geogrids provide stability and reinforcement to the roof system, preventing soil erosion and promoting the growth of vegetation. They also help distribute the weight evenly, making the green roof more structurally sound.

- Q: Are geogrids suitable for reinforcing contaminated soil?

- Yes, geogrids are suitable for reinforcing contaminated soil. Geogrids are made of high-strength synthetic materials that can withstand harsh conditions, including contamination. They are often used to provide reinforcement and stabilization to soil in various applications, including contaminated sites. Geogrids help to distribute loads and reduce soil movement, which can be particularly beneficial in areas with contaminated soil.

- Q: Can geogrids be used for reinforcement in embankments and dams?

- Yes, geogrids can be used for reinforcement in embankments and dams. Geogrids are high-strength synthetic materials that are designed to enhance soil stability and prevent erosion. They are commonly used in civil engineering projects, including embankments and dams, to improve the overall strength and stability of the structures. By providing additional tensile strength to the soil, geogrids help to distribute loads more evenly, reduce settlement, and prevent soil movement.

- Q: How to calculate the amount of geogrid works under what circumstances need to lay geogrid

- According to the road area, [136] asphalt pavement often laying geogrid [0772], [6164] but if the asphalt is thin, can not. Also like municipal roads will generally be used.

- Q: Can geogrids be installed on steep slopes?

- Yes, geogrids can be installed on steep slopes. Geogrids are commonly used in the construction industry to reinforce soil and provide stability on slopes. They are designed to withstand high tensile forces and can effectively reinforce the soil, preventing erosion and slope failure even on steep slopes.

- Q: What are the benefits of using geogrids in construction projects?

- Geogrids offer several benefits in construction projects, including increased soil stability, improved load distribution, and enhanced overall structural integrity. These materials reinforce and stabilize the soil, preventing erosion and reducing the risk of slope failure. Geogrids also help distribute loads more evenly, reducing stress on the construction materials and extending their lifespan. Additionally, geogrids can be cost-effective as they often require less excavation and backfill material, saving time and resources during construction.

- Q: How do geogrids improve the load distribution in pavements?

- Geogrids improve the load distribution in pavements by providing reinforcement and increasing the stability of the structure. They distribute the load more evenly across the pavement, reducing stress on the layers beneath. This helps to prevent cracking, rutting, and other forms of pavement distress, ultimately extending the lifespan of the pavement.

- Q: Can geogrids be used in retaining wall reinforcement systems?

- Yes, geogrids can be used in retaining wall reinforcement systems. Geogrids are commonly used to improve the stability and performance of retaining walls by providing reinforcement and enhancing soil retention. They help to distribute lateral forces and reduce soil movement, thereby increasing the overall strength and durability of the retaining wall.

Send your message to us

Geogrids and Soil Stabilisation Materials - Most Popular Geogrid in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 50000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords