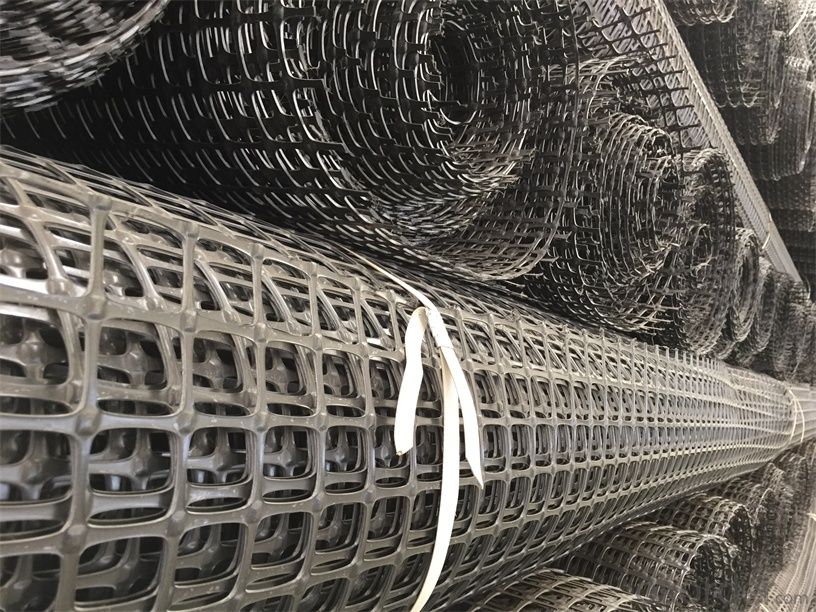

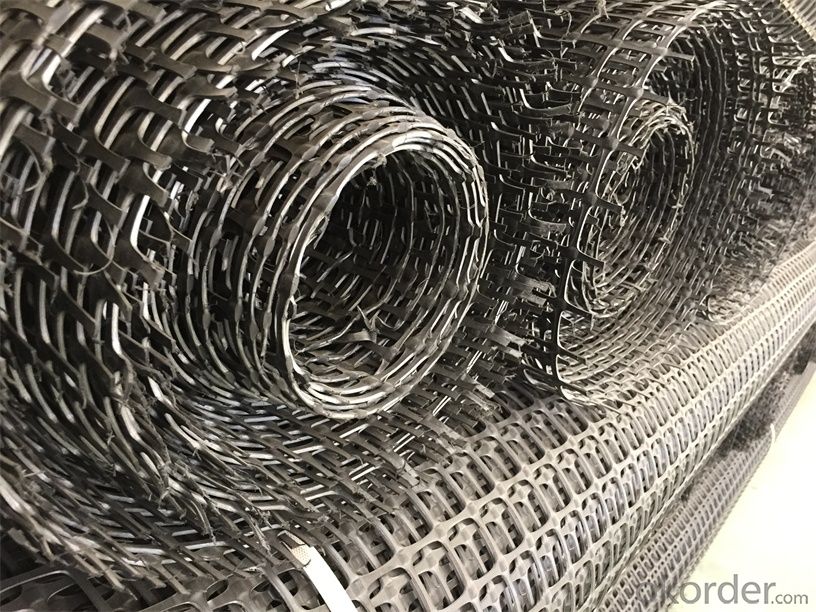

Televev Polyester Geogrids - Geogrid Manufacturer with International Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 50000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Geogrid Introduction:

Fiberglass geogrid is a kind of planar mesh material using alkali-free fiberglass yarn as base body and then coated with high quality modified asphalt. It is warp knitted with oriental structure which gives full play of yarn strength and improves its mechanical property to make the product high tensile, tearing and creep-resistant. Moreover, the composite property of coating with asphalt makes full protection of the fiberglass matrix and greatly improves its wear and shear resistance. All the advantageous functions make the product have a good performance in pavement strengthening, track cracking and solving difficulties of strengthening the bituminous pavement.

Fiberglass Geogrid Features:

1. Light weight, high tensile strength, high modulus, low elongation and good toughness.

2. Corrosion resistance, no long-term creep, long life span.

3. Good physical and chemical stability and good thermal stability.

4. Resistant to fatigue cracking, high-temperature track and low temperature shrinkage cracking.

5. Delaying and decreasing crack reflection.

Specifications | PET20-20 | PET30-30 | PET40-40 | PET50-50 | PET80-80 | PET100-100 | PET120-120 |

Elongation(%) | 10%~15% | ||||||

Vert Tensile strength(KN/m) | 20 | 30 | 40 | 50 | 80 | 100 | 120 |

Horiz Tensile strength(KN/m) | 20 | 30 | 40 | 50 | 80 | 100 | 120 |

Grid(mm) | 12.5×12.5 20×20 24.5×24.5 | ||||||

Width(m) | 1—6 | ||||||

Fiberglass Geogrid Application:

1. Road surface asphalt overlay construction engineering; Asphalt layers

reinforcement.

2. Converting old cement concrete road into composite road; Restraining

reflection cracking caused by block shrinkage.

3. Road extension; Preventing and controlling the cracking caused by new

and old combination and uneven settlement.

4. Treatment of the conjunction between tunnel and bridge or foundation.

Packaging & Shipping:

FAQ:

1. How to order your geogrid ?

a) Tensile strength in warp & weft direction

b) Grid size

c) Roll Width and length

d) Quantity

2. What is the Payment term?

a) TT

b) LC AT SIGHT

c) cash

d) 30% contact value as deposit ,the blance 70% be paid after received the copy of bl .

3. Delivery time

a) 19-25 days after received your depsit .

4. What is MQQ ?

a) 2500 m2 as MQQ , we can also produce sample for you .

Welcome to send your inquiry to us, and if you have any question, we can also help you.

- Q: Polyester warp knitted polyester geogrid and glass fiber geogrid price difference in the price of many components is a ghost?

- Polyester warp knitted polyester coating is PVC glue, glass fiber geogrid is that sensitive asphalt rubber. An anti-corrosion, a alkali resistance. Material is not the same, the appearance is not difficult to distinguish between experts

- Q: What is the effect of geogrid aperture size on performance?

- The effect of geogrid aperture size on performance is that a smaller aperture size generally leads to better performance. This is because a smaller aperture size allows for better soil confinement and interlocking, resulting in improved stability, load distribution, and overall performance of the geogrid. A larger aperture size, on the other hand, may lead to reduced confinement and interlocking, potentially compromising the geogrid's performance.

- Q: What are the potential drawbacks of using geogrids?

- Some potential drawbacks of using geogrids include their high cost compared to other soil stabilization methods, the need for proper installation and maintenance to ensure effectiveness, and limitations in their ability to withstand certain extreme environmental conditions such as high temperatures or chemical exposure. Additionally, geogrids may not be suitable for all soil types or site conditions, requiring a thorough analysis and consideration of alternative solutions.

- Q: How to calculate the amount of geogrid works under what circumstances need to lay geogrid

- Of course, mainly depends on what kind of material you are using geogrid, I said above is fiberglass geogrid.

- Q: Can geogrids be used in soil stabilization for parking lots?

- Yes, geogrids can be used in soil stabilization for parking lots. Geogrids are strong and flexible materials that can be placed beneath the surface of the parking lot to improve the load-bearing capacity of the soil, reduce soil erosion, and increase the overall stability of the parking lot. By distributing the weight of vehicles more evenly, geogrids help to prevent rutting, cracking, and other damages that can occur due to heavy traffic and poor soil conditions.

- Q: Can geogrids be used in retaining walls for residential applications?

- Yes, geogrids can be used in retaining walls for residential applications. Geogrids are commonly used in retaining walls to enhance stability and improve the overall performance of the structure. They provide reinforcement and prevent soil erosion, which is crucial for the durability and longevity of residential retaining walls.

- Q: How thick is the need to lay a layer of Geogrid in the new highway earthwork backfill? Specific foundation to pave the way to solve

- The road at the interface, and the next day than the Square Street shop

- Q: What is the use of glass fiber grille paving asphalt road

- Silicon oxide is an inorganic material, its physical and chemical properties are very stable, and has the advantages of high strength, high modulus, high wear resistance and excellent cold resistance, no long-term creep

- Q: Geogrid specification TGSG40-40 what meaning

- Geogrid specification TGSG40-40 what meaningZenganiu1987 | browse 2395Posted on 2017-10-08 15:52 best answerBiaxial tensile plastic geogrid, GB standard, vertical transverse tension are 40KN

- Q: What are the quality control measures for geogrid manufacturing?

- Quality control measures for geogrid manufacturing include: 1. Raw material testing: Ensuring that the materials used in the manufacturing process meet the required specifications and quality standards. 2. Process control: Implementing strict monitoring and control of each stage of the manufacturing process to ensure consistency and adherence to quality standards. 3. Product testing: Conducting rigorous testing of the geogrids at various stages of production to evaluate their mechanical properties, such as tensile strength, elongation, and durability. 4. Statistical process control: Using statistical methods to monitor and control the manufacturing process, identifying any deviations from the desired quality standards and taking appropriate corrective actions. 5. Quality inspections: Conducting regular inspections of the manufacturing facilities and equipment to ensure proper maintenance and calibration, preventing any potential quality issues. 6. Traceability: Implementing a system to track and trace each batch of geogrids manufactured, ensuring accountability and facilitating prompt recall or corrective actions if necessary. 7. Continuous improvement: Regularly reviewing and analyzing quality data, customer feedback, and industry trends to identify areas for improvement and implement corrective and preventive measures. By implementing these quality control measures, geogrid manufacturers can ensure consistent production of high-quality products that meet the required standards and customer expectations.

Send your message to us

Televev Polyester Geogrids - Geogrid Manufacturer with International Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 50000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords