Geogrids for Velocity Slopes - Polyester Geogrids with High Tensile Strength and Best Quality

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction:

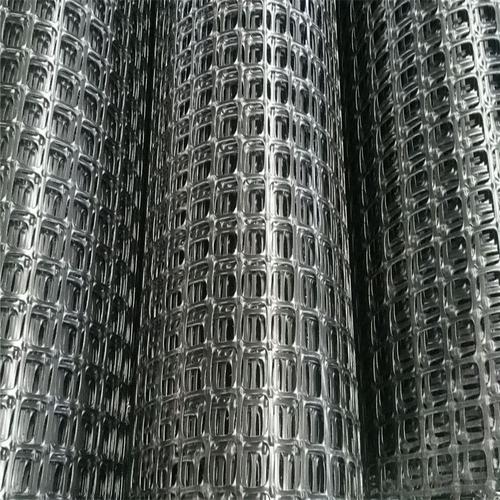

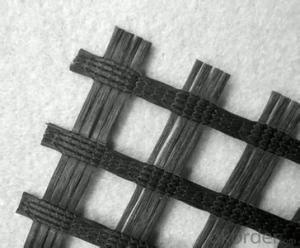

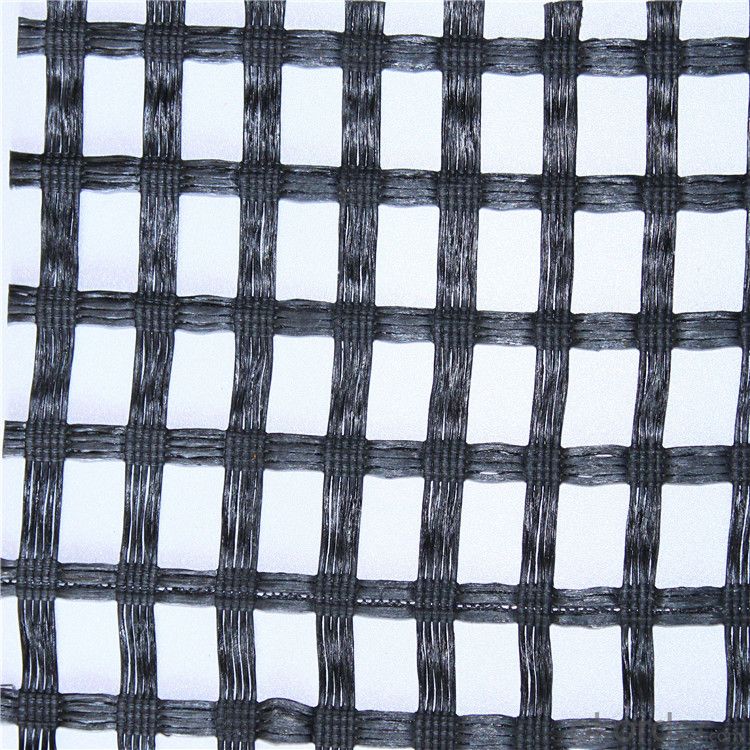

Polyester geogrid is a new kind of favorable earthwork base material to strength the road surface and roadbed, which composed of high strength polyester yarns coated with an inorganic sizing agent.

Features:

1) High tensile strength

2) High tear-resistant

3) Strong combination with gravel and soil

Specifications :

Mesh size(mm) | 25.4×25.4 Or 12.5×12.5 | |||||

Breaking strength ≥(KN/m) | Warp direction | 30 | 50 | 80 | 100 | 120 |

Across warp | 30 | 50 | 80 | 100 | 120 | |

Elongation at break ≤(%) | Warp direction | 3 | ||||

Across warp | 3 | |||||

Elasticity modulus(GPA) | 67 | |||||

Thermal tolerance | -100~280℃ | |||||

Width | 1~6m | |||||

Function:

This product is made by weaving and covering fiberglass filament. It is featured by high vertical and horizontal tensile

strength, low unit extension, high flexibility, and favorable high and low temperature resistance. The products after

surface covering own the favorable property of alkali resistance and aging resistance.

It is used widely to increase the asphalt road surface, concrete road and roadbed (both soft and hard road surfaces).

Compared with the traditional road surface, it reduces the cost, prolong the service life, and avoid the reflection road

crackle.

This product is also used to strengthen the soft land, such as railway, airport, irrigation work, and dyke, etc, and the

roadbed 。

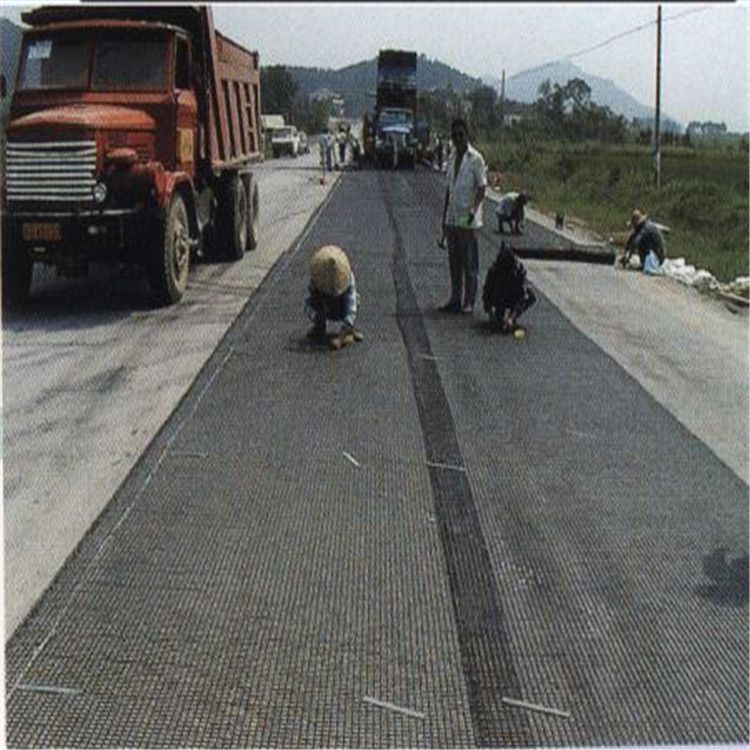

Image of Polyester Geogrid

- Q: How do geogrids improve the performance of asphalt pavements?

- Geogrids improve the performance of asphalt pavements by providing reinforcement and stabilization. They enhance the tensile strength of the pavement, preventing cracking and rutting caused by traffic loads. Additionally, geogrids reduce reflective cracking by distributing the stress from underlying layers, improving the overall structural integrity and lifespan of the pavement.

- Q: How do geogrids improve the performance of geotechnical structures?

- Geogrids improve the performance of geotechnical structures by enhancing their load-bearing capacity, reducing soil erosion, and providing stability. These synthetic materials are used to reinforce soil, increasing its strength and preventing it from shifting or settling. By distributing the load more evenly, geogrids minimize the potential for structural failure and improve overall stability. Additionally, they help to control soil erosion by stabilizing slopes and retaining walls, reducing the risk of landslides and erosion-related damage.

- Q: What are the geotechnical testing items for Subgrade?

- Longitudinal and transverse tensile strength and elongation

- Q: What are the advantages of using geogrids in ground reinforcement?

- Geogrids offer several advantages in ground reinforcement. Firstly, they provide increased stability and support to the soil by distributing loads more evenly. This helps prevent soil erosion, subsidence, and deformation, making them ideal for areas with weak or unstable soils. Secondly, geogrids enhance the load-bearing capacity of the ground, allowing for the construction of structures and infrastructure on softer or less stable ground. Additionally, they improve drainage and reduce the risk of water accumulation, which can weaken the soil. Lastly, geogrids are cost-effective and environmentally friendly, as they require less excavation and use of natural resources compared to traditional ground reinforcement methods.

- Q: How do geogrids improve the performance of geotextile-reinforced retaining walls?

- Geogrids improve the performance of geotextile-reinforced retaining walls by providing additional strength and stability. They help distribute the load more evenly across the geotextile, reducing stress and potential failure points. Geogrids also prevent excessive lateral movement and improve overall structural integrity, increasing the retaining wall's ability to withstand external forces such as soil pressure.

- Q: What are the factors that affect the design and selection of geogrids for geosynthetic reinforcement of steep slopes?

- There are several factors that affect the design and selection of geogrids for geosynthetic reinforcement of steep slopes. Some of the key factors include the slope angle and height, soil type and properties, anticipated loads and stresses, environmental conditions, and project-specific requirements. The geogrid material, strength, aperture size, and installation method must be carefully considered to ensure optimal performance and long-term stability of the reinforced slope. Additionally, factors such as cost, availability, and durability may also influence the selection of geogrids for a particular project.

- Q: Can geogrids be used in retaining walls?

- Yes, geogrids can be used in retaining walls. Geogrids are commonly used as a reinforcement material in retaining walls to enhance their stability and strength.

- Q: Are geogrids suitable for reinforcement of soft subgrades?

- Yes, geogrids are suitable for reinforcement of soft subgrades. Geogrids have been proven to effectively improve stability and strength in soft subgrade soils by distributing loads and reducing settlement. They provide additional tensile strength, preventing excessive deformation and enhancing the overall performance of the subgrade.

- Q: Can geogrids be used in coastal erosion control?

- Yes, geogrids can be used in coastal erosion control. Geogrids are often employed as a reinforcement material to stabilize soil and prevent erosion in coastal areas. They can be used to strengthen slopes, retain beach or dune materials, and provide stability to coastal structures like seawalls or revetments. Geogrids are designed to withstand the harsh coastal environment and can effectively reduce the impact of wave and tidal action on the shoreline, making them a valuable tool in coastal erosion control efforts.

- Q: What is the principle of geogrid?

- GSZ: 1 what are the characteristics of high strength steel wire, steel plastic composite geogrid tension by warp knitting bear, resulting in high tensile modulus at low strain capacity, vertical and horizontal rib synergistic effect, give full play to the role of Geogrid on soil type. 2, steel plastic composite geogrid vertical steel rib weft woven into nets, an outer coating layer forming a steel wire and the outer coating layer can destroy the function of coordination, elongation is very low (less than 3%). The main force unit of steel plastic composite geogrid is steel wire, and the creep is very low. 3, through the production process of plastic surface treatment, suppress the rough pattern, in order to enhance the surface roughness of the grid, improve the steel plastic composite geogrid and soil friction coefficient. 4, steel plastic composite geogrid width of up to 6m, to achieve high efficiency, economic effect of reinforcement. 5, steel plastic composite geogrid used high-density polyethylene can ensure that: at room temperature will not be affected by acid and alkali and salt solution, or oil erosion; will not be dissolved by water or microbial damage. At the same time, the high molecular weight of polyethylene is also sufficient to resist ultraviolet radiation caused by aging. The grille stress aspect rib synergistic effect, can not generate node crack or damage. But in the actual project, after the packing compaction, therefore has not been subjected to the ultraviolet light and the oxygen erosion, therefore completely may satisfy the permanent construction request.

Send your message to us

Geogrids for Velocity Slopes - Polyester Geogrids with High Tensile Strength and Best Quality

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords