Geosynthetic Clay Liner (GCL) /Lake Hydraulic Barriers

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

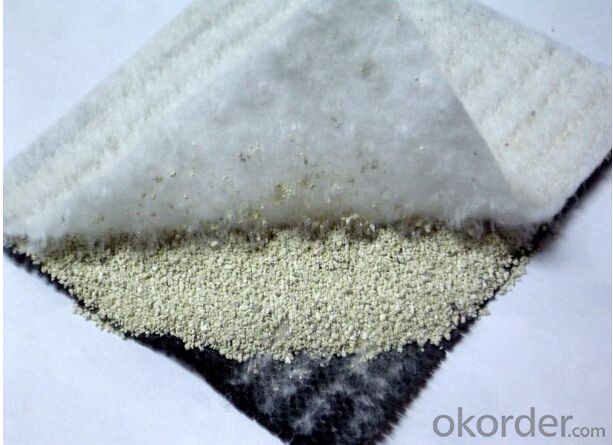

Geosynthetic Clay Liner (GCL) /Lake Hydraulic Barriers

Specification:

Mass per unit ≥ 4000g / m²

Width: 4-6 m

size: 5.8 x 30m , or customized

bentonite sandwiched between two layers of geotextile

Features:

1) compacted with clay liner, it has the advantages of

small size, light weight, good flexibility and compactibility

2) easy for construction and suitable for uneven settlement.

3) not affected by temperature

4) permanent waterproofness

5) eco-friendly

Applications:

Landfill sealing

Liquid containment

Secondary containment

Mining

GCL Technical Index

Item | Specification | ||||

GCL-NP | GCL-OF | GCL-AH | |||

Mass per unit g/m2 | ≥ 4000 (not less than the specified value) | ≥ 4000 (not less than the specified value) | ≥ 4000 (not less than the specified value) | ||

GCL expansion index ml/2g | ≥24 | ≥24 | ≥24 | ||

Blue absorption power g/100g | ≥ 30 | ≥ 30 | ≥ 30 | ||

Tensile Strength N/ 100mm | ≥ 600 | ≥ 700 | ≥ 600 | ||

Elongation at maximum load % | ≥ 10 | ≥ 10 | ≥ 8 | ||

Peel strength N / 100mm | Nonwoven geotextile and woven geotextile | ≥ 40 | ≥ 40 | - | |

PE geommebrane and nonwoven geotextile | - | ≥ 30 | - | ||

Permeability coefficient m/s | ≤ 5.0x10-11 | ≤ 5.0x10-12 | ≤ 1.0x10-12 | ||

Hydrostatic pressure resistant | 0.4 Mpa , 1h, no leakage | 0.6 Mpa ,1h,no leakage | 0.6Mpa ,1h, no leakage | ||

Filter loss ml | ≤ 18 | ≤ 18 | ≤ 18 | ||

Durability of bentonite ml/ 2g | ≥ 20 | ≥ 20 | |||

FAQ:

How many quantity for one 20'' container?

About 5,000m2, 16rolls

What's your delivery time?

About 15-20days against deposit received

. What's your package?

Per roll with two pieces woven bag

- Q: In addition to cement, but also add gelling agent

- The development of cementitious materials has a long history, people use the earliest cementitious material - clay to wipe the simple building. Then there are cement and other building materials and cementitious materials have a great relationship.

- Q: Can earthwork products be used in bridge abutment construction?

- Yes, earthwork products can be used in bridge abutment construction. Earthwork products such as soil, fill material, and geotextiles are commonly utilized in the construction of bridge abutments to provide stability, improve drainage, and prevent erosion. These materials can be properly engineered and compacted to meet the required specifications for bridge abutment construction.

- Q: Are earthwork products suitable for use in vineyard construction?

- Yes, earthwork products are suitable for use in vineyard construction. They can be used for various purposes such as leveling the ground, creating terraces, constructing irrigation systems, and building retaining walls. Earthwork products provide stability and support to the vineyard infrastructure, ensuring proper drainage and erosion control.

- Q: How do geopipes help in subsurface irrigation systems?

- Geopipes help in subsurface irrigation systems by efficiently delivering water directly to the plant roots, reducing water wastage and evaporation. These pipes are designed to be buried underground, allowing for uniform water distribution and minimizing surface runoff. Additionally, geopipes prevent weed growth and reduce the risk of water contamination, making them a sustainable and effective solution for irrigation.

- Q: Construction and sales business tax how to calculate?

- For taxpayers engaged in construction, repair, decoration works, regardless of how the other party settlement, the turnover should include the use of raw materials and other materials and power prices, including

- Q: How do earthwork products help with habitat restoration?

- Earthwork products such as soil, sand, and mulch are crucial for habitat restoration as they provide the necessary materials to recreate or enhance natural environments. These products can be used to reshape landscapes, create new habitats, improve soil quality, and provide a suitable foundation for plant growth. By utilizing earthwork products, habitat restoration projects can effectively recreate or enhance ecosystems, providing a sustainable environment for various plants and animals to thrive.

- Q: What are the benefits of using geosynthetic clay liners in pond liners?

- Geosynthetic clay liners offer several benefits when used in pond liners. Firstly, they provide excellent hydraulic conductivity, reducing the risk of water seepage and leakage. Additionally, they have high tensile strength and can withstand heavy loads, ensuring the stability and durability of the pond liner. Geosynthetic clay liners also have a self-healing property, meaning they can reseal themselves if punctured, enhancing their overall effectiveness. Moreover, these liners are environmentally friendly, as they are made from natural materials and do not release harmful chemicals into the water. Overall, the use of geosynthetic clay liners in pond liners ensures efficient water containment, longevity, and minimal environmental impact.

- Q: What are the three categories of civil engineering materials classified according to the basic composition?

- Inorganic materials: metal and non-metallic materials. Organic materials: composite materials: inorganic non-metallic materials and organic materials composite (steel brazing concrete, asphalt concrete, polymer concrete, polymer mortar, etc.). Plant material, asphalt material and high score material.

- Q: Are earthwork products resistant to extreme temperature variations?

- Yes, earthwork products are generally resistant to extreme temperature variations due to their natural composition and ability to withstand thermal expansion and contraction.

- Q: How do earthwork products help with shoreline stabilization?

- Earthwork products, such as geotextiles, geogrids, and erosion control blankets, play a crucial role in shoreline stabilization. These products are designed to control soil erosion, prevent sediment runoff, and reinforce the stability of the shoreline. Geotextiles act as a filter, allowing water to pass through while retaining soil particles, which helps to prevent erosion and maintain the shoreline's integrity. Geogrids provide structural support by distributing the load across a wider area, improving stability and preventing soil movement. Erosion control blankets, on the other hand, protect the soil from water and wind erosion, promoting vegetation growth and strengthening the shoreline's resistance to erosion. In summary, earthwork products effectively mitigate erosion, reduce sedimentation, and enhance the overall stability of shorelines.

Send your message to us

Geosynthetic Clay Liner (GCL) /Lake Hydraulic Barriers

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords