Geocells and Various Types of Geogrids Suppliers from China

- Loading Port:

- Guangzhou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 9999999 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We provide various types of Geogrids products, and send samples free of charge as required. We are a supplier from China, providing you with the latest products and prices in real time. No matter what kind of material and specification you need, we can meet your needs.

What is a geogrid?

Geogrid is one of the main geosynthetics. Compared with other geosynthetics, it has unique performance and efficacy. It is often used as reinforcement of reinforced soil structures or composite materials. The geogrid is divided into four categories: plastic geogrid, steel plastic geogrid, glass fiber geogrid and polyester warp knitted polyester geogrid. The grid is a two-dimensional grid or three-dimensional grid with a certain height, which is made of polypropylene, polyvinyl chloride and other high molecular polymers through thermoplastic or molding. When used as a civil engineering, it is called a geogrid.

Classification of geogrids

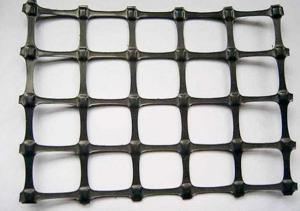

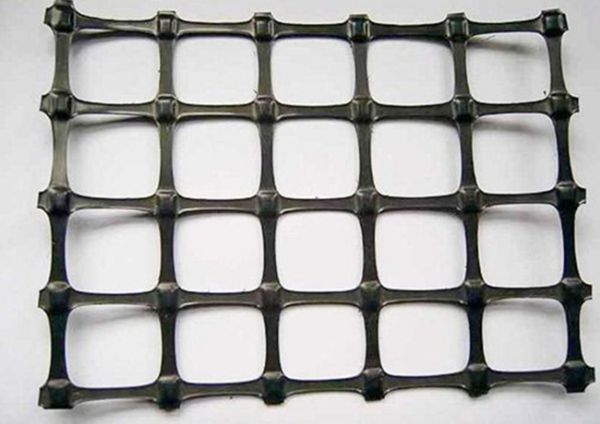

1. Plastic geogrids

The polymer mesh with square or rectangular shape formed by stretching can be divided into unidirectional stretching and biaxial stretching according to the different stretching directions during manufacturing. It is punched on the extruded polymer sheet (raw materials are mostly polypropylene or high-density polyethylene), and then directionally stretched under heating conditions. The unidirectional stretching grid is only made by stretching along the length direction of the plate; The bidirectional stretching grid is made by stretching the unidirectional stretching grid in the direction perpendicular to its length.

2. Mine geogrids

The mining grid is a kind of plastic wall protection net used in coal mine, which is made of polypropylene as the main raw material. After being treated with flame retardant and anti-static technology, the overall structure of the "double anti" plastic net is formed by means of two-way stretching. The product is convenient for construction, low cost, safe and beautiful.

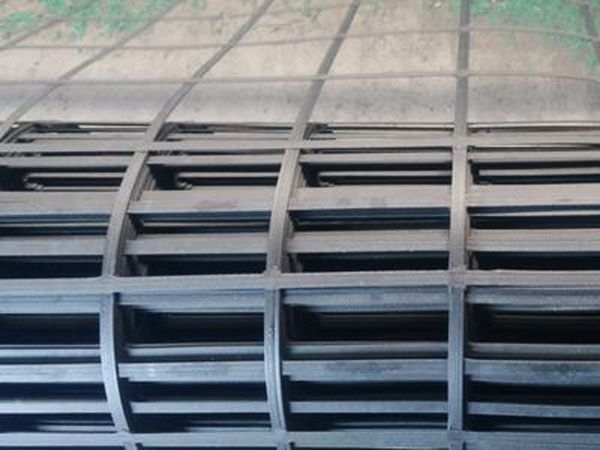

3. Steel plastic geogrids

The steel plastic geogrid is made of high-strength steel wire (or other fibers), after special treatment, polyethylene (PE), and other additives. It is extruded into a composite high-strength tensile strip with rough embossed surface. This single strip is formed by welding its junction points with the fusion welding technology of special strengthening and bonding, which is compiled or clamped at a certain distance longitudinally and transversely. It is a reinforced geogrid.

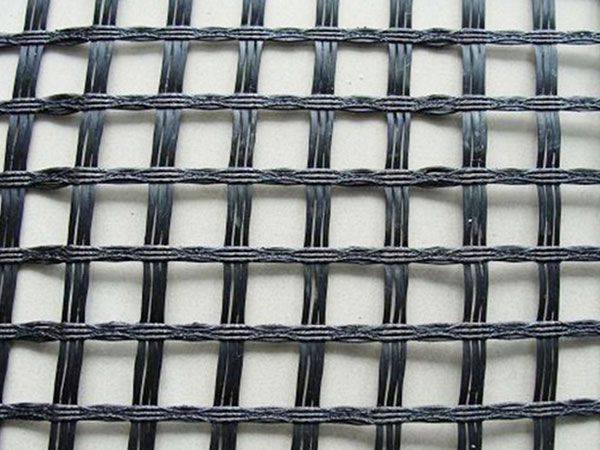

4. Glass fiber grid

Glass fiber geogrid is a network structure material made of glass fiber with a certain weaving process. In order to protect the glass fiber and improve the overall performance, it is made of a special coating process. The main components of glass fiber are: silicon oxide, an inorganic material, with extremely stable physical and chemical properties, high strength, high modulus, high wear resistance and excellent cold resistance, without long-term creep; Good thermal stability; The mesh structure makes the aggregate locked and restricted; Improve the bearing capacity of asphalt mixture. Because the surface is coated with special modified asphalt, it has dual composite properties, greatly improving the wear resistance and shear capacity of the geogrid.

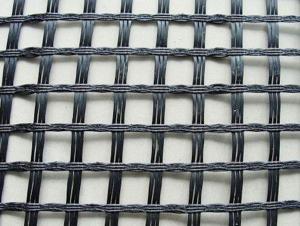

5. Polyester warp knitted grid

Polyester warp knitted geogrid is made of high-strength polyester fiber. The warp knitted directional structure is adopted, and the warp and weft yarns in the fabric are not bent with each other. The intersection is bound with high-strength fiber filaments to form a firm junction, giving full play to its mechanical properties. The high-strength polyester fiber warp knitted geogrid has high tensile strength, small extension force, large tear resistance strength, small vertical and horizontal strength difference, UV aging resistance, wear resistance, corrosion resistance, light weight, and strong locking force with soil or gravel, It plays a significant role in enhancing the shear resistance of soil and improving the integrity and load capacity of soil.

6. Biaxially stretched plastic geogrids

It is applicable to all kinds of embankment and subgrade reinforcement, slope protection, tunnel wall reinforcement, and permanent bearing foundation reinforcement of large airports, parking lots, wharf freight yards, etc.

7. Uniaxial tensile grid

Unidirectional tensile geogrid is a kind of high-strength geo material made of high molecular polymer as the main raw material, adding certain anti ultraviolet and anti-aging additives, reorienting and arranging the originally scattered chain molecules in a linear state through unidirectional stretching, extruding and pressing them into thin plates and punching regular pore networks, and then stretching them longitudinally. In this process, the polymer becomes a directional linear state and forms a long elliptical reticular integral structure with uniform distribution and high node strength.

Characteristics of geogrid

1. With high strength, low creep and adaptability to various environmental soils, it can fully meet the requirements of high retaining walls in high-grade highways.

2. It can effectively improve the interlocking and occlusion of the reinforced bearing surface, greatly enhance the bearing capacity of the foundation, effectively restrain the lateral displacement of the soil, and enhance the stability of the foundation.

3. Compared with the traditional grid, it has the characteristics of high strength, strong bearing capacity, corrosion resistance, anti-aging, large friction coefficient, uniform hole, convenient construction, long service life, etc.

4. It is more suitable for deep-sea operations and bank reinforcement, and fundamentally solves the technical problems of low strength, poor corrosion resistance, short service life and other technical problems caused by long-term seawater erosion of gabions made of other materials.

5. It can effectively avoid construction damage caused by rolling and damage of machines and tools during construction.

Application field of geogrid

1. It is applicable to subgrade reinforcement and pavement reinforcement of various highways, railways and airports.

2. It is applicable to the reinforcement of permanent bearing foundations such as large parking lots and wharf freight yards.

3. It is applicable to slope protection of railways and highways.

4. Applicable culvert reinforcement.

5. It is applicable to the secondary reinforcement of soil slope after one-way tensile geogrid reinforcement to further strengthen the soil slope and prevent water and soil loss.

6. Reinforcement of mines and tunnels.

Use of geogrid

The geogrid is applicable to the reinforcement of various dykes and embankments, subgrade, slope protection and tunnel wall. Foundation reinforcement for permanent bearing of large airports, parking lots, wharf freight yards, etc.

1. Geogrid is used to increase the bearing capacity of road (ground) foundation and prolong the service life of road (ground) foundation.

2. The geogrid is used to prevent the road (ground) surface from collapsing or cracking, and keep the ground beautiful and tidy.

3. Geogrid is used to facilitate construction, save time and labor, shorten construction period and reduce maintenance costs.

4. The geogrid is used to prevent cracks in the culvert.

5. Geogrid is used to strengthen soil slope and prevent water and soil loss.

6. Geogrid is used to reduce the thickness of cushion and save the cost.

7. Geogrid is used to support the stability and greening environment of grass planting mat on the slope.

8. Geogrid can effectively resist the transmission of seismic force, and plays an important role in strengthening the seismic stiffness, strength and stability of embankment.

- Q: Can geogrids be used in temporary construction access mats?

- Yes, geogrids can be used in temporary construction access mats. Geogrids are commonly employed in such mats to provide reinforcement and stability, making them suitable for heavy equipment and vehicle traffic during construction.

- Q: Can geogrids be used in ground improvement projects?

- Yes, geogrids can be used in ground improvement projects. Geogrids are commonly used to reinforce and stabilize soil, improving its bearing capacity and preventing soil erosion. They are effective in a variety of ground improvement applications such as road construction, retaining walls, and slope stabilization.

- Q: How do geogrids help in reducing the risk of differential settlement of structures?

- Geogrids help in reducing the risk of differential settlement of structures by providing reinforcement and improving the load-bearing capacity of the soil. They act as a stabilizing layer, distributing vertical and horizontal forces evenly, which prevents uneven settling of the foundation. This helps maintain the structural integrity of the building and minimizes the potential for damage or structural failure.

- Q: How are geogrids used in road construction?

- Geogrids are used in road construction to reinforce the soil and provide additional strength to the pavement. They are laid within the layers of the road, typically between the subgrade and the base course, to distribute the load and prevent the spreading of cracks. Geogrids help improve the stability and durability of the road, reducing maintenance needs and extending its lifespan.

- Q: Can geogrids be used in soft soil conditions?

- Yes, geogrids can be used in soft soil conditions. Geogrids are often used in such conditions to improve the stability and load-bearing capacity of the soil. They are designed to provide reinforcement and prevent soil movement, making them an effective solution for soft soil conditions.

- Q: What is the lifespan of geogrids in typical applications?

- The lifespan of geogrids in typical applications can vary depending on factors such as the type of geogrid, its quality, installation methods, and the environmental conditions it is exposed to. However, geogrids are designed to be highly durable and have a lifespan ranging from 20 to 100 years in most cases.

- Q: Where can I do three to the geogrid test?

- There's a lot more to do. The key is where you are. See if there is a recent. The test of top breaking, puncture and tear of geotextiles.

- Q: What are the design considerations for geogrid reinforcement?

- Some design considerations for geogrid reinforcement include the type and strength of the geogrid material, the required level of soil stabilization, the anticipated loads and stresses on the reinforced soil structure, and the desired lifespan of the structure. Other factors to consider include soil characteristics, installation and construction procedures, and environmental conditions. Additionally, the design should account for factors such as slope stability, drainage, and potential settlement.

- Q: The difference between the overlap length and the overlapping width of the geotextile in reinforced embankment

- The installation of geotextiles is usually done by means of overlapping, stitching and welding. The width of the stitching and welding is generally 0.1M or more, and the overlap width is generally more than 0.2M.

- Q: What are the quality control measures for geogrid manufacturing?

- Quality control measures for geogrid manufacturing include: 1. Raw material testing: Ensuring that the materials used in the manufacturing process meet the required specifications and quality standards. 2. Process control: Implementing strict monitoring and control of each stage of the manufacturing process to ensure consistency and adherence to quality standards. 3. Product testing: Conducting rigorous testing of the geogrids at various stages of production to evaluate their mechanical properties, such as tensile strength, elongation, and durability. 4. Statistical process control: Using statistical methods to monitor and control the manufacturing process, identifying any deviations from the desired quality standards and taking appropriate corrective actions. 5. Quality inspections: Conducting regular inspections of the manufacturing facilities and equipment to ensure proper maintenance and calibration, preventing any potential quality issues. 6. Traceability: Implementing a system to track and trace each batch of geogrids manufactured, ensuring accountability and facilitating prompt recall or corrective actions if necessary. 7. Continuous improvement: Regularly reviewing and analyzing quality data, customer feedback, and industry trends to identify areas for improvement and implement corrective and preventive measures. By implementing these quality control measures, geogrid manufacturers can ensure consistent production of high-quality products that meet the required standards and customer expectations.

Send your message to us

Geocells and Various Types of Geogrids Suppliers from China

- Loading Port:

- Guangzhou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 9999999 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords