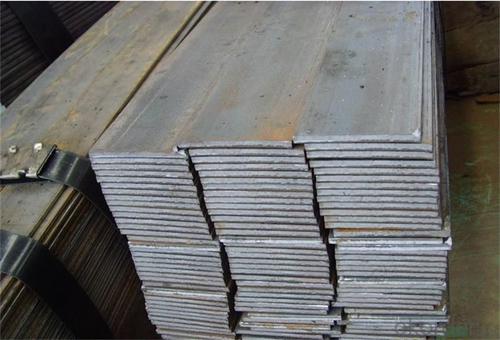

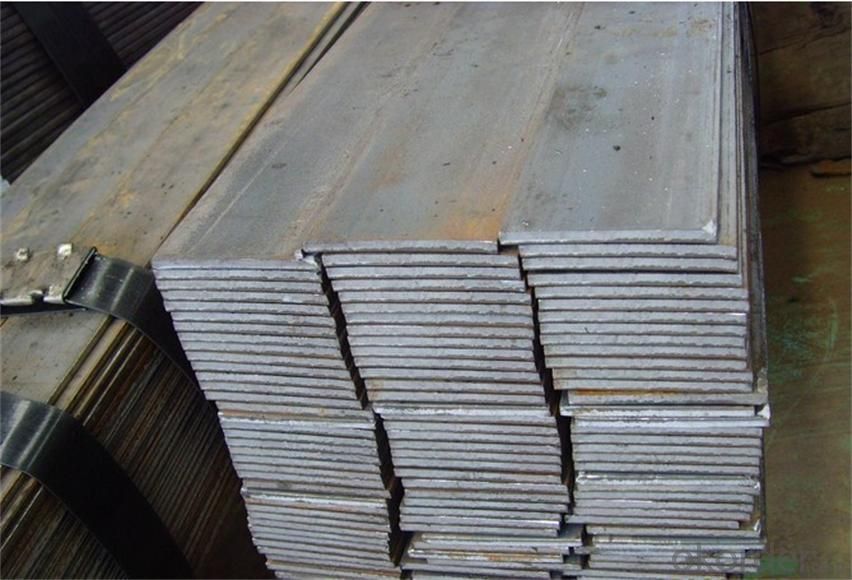

GB Standard Flat Bar/Steel Flat Bar/Hot Rolled Spring Steel Flat Bar

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 PCS

- Supply Capability:

- 38000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

GB Standard Flat Bar/Steel Flat Bar/Hot Rolled Spring Steel Flat Bar Details

| Grade: | Q235,Q345/SS400,SS540 | Standard: | ASTM,GB,JIS | Thickness: | 2.5mm-20mm |

| Width: | 12mm-150mm | Length: | customized flat steel | Place of Origin: | China (Mainland) |

| Technique: | Hot Rolled | Model Number: | customized flat steel | Application: | structure construction/making fence |

Packaging & Delivery

| Packaging Detail: | Mills standard export strong Packing |

| Delivery Detail: | 25-45 days |

GB Standard Flat Bar/Steel Flat Bar/Hot Rolled Spring Steel Flat Bar Specifications

Full size

Grade:Q195, Q215, Q235

Low price

GB Standard Flat Bar/Steel Flat Bar/Hot Rolled Spring Steel Flat Bar Description

Grade:Q235-Q345/SS400-SS540/S235JR-355JR

Standard: GB/JIS/EN/ASTM

Steel flat bar thick : 2.5-20mm

Steel flat bar wide : 12-150mm

Steel flat bar length :Any you want

GB Standard Flat Bar/Steel Flat Bar/Hot Rolled Spring Steel Flat Bar Pictures

- Q: Can steel sheets be used for making shipping containers?

- Yes, steel sheets can be used for making shipping containers. Steel is a commonly used material in the construction of shipping containers due to its strength, durability, and ability to withstand harsh weather conditions.

- Q: Are steel sheets suitable for roofing systems?

- Yes, steel sheets are suitable for roofing systems. They are durable, long-lasting, and resistant to various weather conditions, making them an ideal choice for protecting buildings from the elements. Additionally, steel sheets are lightweight, easy to install, and require minimal maintenance, making them a cost-effective option for roofing systems.

- Q: How do steel sheets compare to aluminum sheets in terms of strength?

- In general, steel sheets exhibit greater strength than aluminum sheets. Steel possesses a reputation for its remarkable tensile strength, enabling it to endure substantial forces without distorting or fracturing. Conversely, aluminum sheets demonstrate lower tensile strength and are inclined to bend or distort when subjected to heavy loads. Nevertheless, it is important to acknowledge that aluminum sheets can still possess sufficient strength for numerous applications, particularly when taking into account their lower density when compared to steel. Moreover, aluminum sheets possess the advantage of being lighter in weight, resistant to corrosion, and exhibiting superior thermal conductivity in relation to steel sheets. Consequently, the decision between steel and aluminum sheets hinges upon the specific requirements of the project, taking into consideration factors such as strength, weight, resistance to corrosion, and thermal properties.

- Q: Are the steel sheets suitable for automotive applications?

- Yes, steel sheets are commonly used in automotive applications due to their high strength, durability, and formability. They provide structural support, enhance crash safety, and can be easily shaped into various automotive components, making them suitable for the automotive industry.

- Q: What are the different types of steel sheet finishes for automotive applications?

- There are several different types of steel sheet finishes commonly used in automotive applications. These finishes are applied to the surface of the steel sheet to enhance its appearance, durability, and corrosion resistance. One common type of finish is the mill finish, which is the natural finish of the steel sheet after it has been hot or cold rolled. This finish has a dull gray appearance and is typically used for applications where aesthetics are not a major concern. Another popular finish is the galvanized finish, which involves coating the steel sheet with a layer of zinc to protect it from corrosion. This finish provides excellent corrosion resistance and is commonly used in automotive body panels and structural components. There is also the painted finish, where the steel sheet is coated with a layer of paint. This finish not only improves the aesthetics of the steel sheet but also provides an added layer of protection against corrosion. Painted finishes can come in a variety of colors and textures, allowing for customization and branding options. Additionally, there are specialized finishes such as the electro-galvanized finish, which involves applying a thin layer of zinc to the steel sheet through an electroplating process. This finish provides enhanced corrosion resistance and is commonly used in automotive parts that require a high level of protection against rust. Lastly, there is the brushed or polished finish, which involves mechanically polishing the surface of the steel sheet to create a smooth and reflective appearance. This finish is often used for decorative purposes in automotive applications, such as trim or accents. In summary, the different types of steel sheet finishes for automotive applications include mill finish, galvanized finish, painted finish, electro-galvanized finish, and brushed/polished finish. Each type of finish offers unique benefits in terms of appearance, durability, and corrosion resistance, allowing manufacturers to choose the most suitable option for their specific automotive application.

- Q: Are steel sheets suitable for interior wall cladding?

- Yes, steel sheets are suitable for interior wall cladding. They provide a durable and modern aesthetic, are resistant to moisture and fire, and can be customized to fit various design styles.

- Q: Are steel sheets resistant to chemicals?

- Yes, steel sheets are generally resistant to chemicals.

- Q: Can steel sheets be used for automotive body panels?

- Yes, steel sheets can be used for automotive body panels. Steel is a commonly used material in the automotive industry due to its strength, durability, and cost-effectiveness. Steel sheets provide the necessary structural support and protection required for automotive body panels.

- Q: Can steel sheets be used in construction projects?

- Yes, steel sheets can be used in construction projects. They are commonly used as roofing and wall cladding materials, as well as for structural elements such as beams, columns, and trusses. Steel sheets offer several advantages in construction, including durability, strength, and fire resistance. They are versatile and can be cut, shaped, and welded to meet specific project requirements.

- Q: What are the different sheet metal joining techniques for steel sheets?

- There are several different sheet metal joining techniques for steel sheets, including welding, riveting, clinching, adhesive bonding, and mechanical fastening. Each method has its own advantages and limitations, and the choice of technique depends on factors such as the desired strength, aesthetics, and cost of the joint.

Send your message to us

GB Standard Flat Bar/Steel Flat Bar/Hot Rolled Spring Steel Flat Bar

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 PCS

- Supply Capability:

- 38000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords