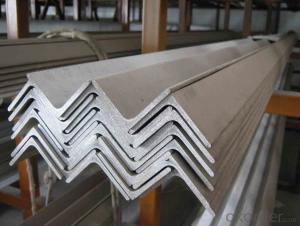

GB Q235B high quality angle steel 20-250MM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Angle Steel Details:

| Minimum Order Quantity: | 25mtons | Unit: | m.t. | Loading Port: | China Main Port |

| Supply Ability: | 80000-100000MTS/YEAR | Payment Terms: | TT or LC |

Product Description:

Specifications of Angle Steel

1. Invoicing on theoretical weight or actual weight as customer request

2. Length: 6m, 9m, 12m as following table

3. Sizes

Sizes: 25mm-250mm | ||

a*t | ||

25*2.5-4.0 | 70*6.0-9.0 | 130*9.0-15 |

30*2.5-6.6 | 75*6.0-9.0 | 140*10-14 |

36*3.0-5.0 | 80*5.0-10 | 150*10-20 |

38*2.3-6.0 | 90*7.0-10 | 160*10-16 |

40*3.0-5.0 | 100*6.0-12 | 175*12-15 |

45*4.0-6.0 | 110*8.0-10 | 180*12-18 |

50*4.0-6.0 | 120*6.0-15 | 200*14-25 |

60*4.0-8.0 | 125*8.0-14 | 250*25 |

5. Payment terms:

1).100% irrevocable L/C at sight.

2).30% T/T prepaid and the balance against the copy of B/L.

3).30% T/T prepaid and the balance against L/C

6.Material details:

Alloy No | Grade | Element (%) | |||||

C | Mn | S | P | Si | |||

|

|

|

|

|

|

| |

Q235 | B | 0.12—0.20 | 0.3—0.7 | ≤0.045 | ≤0.045 | ≤0.3 | |

|

|

|

|

|

|

| |

Alloy No | Grade | Yielding strength point( Mpa) | |||||

Thickness (mm) | |||||||

≤16 | >16--40 | >40--60 | >60--100 | ||||

≥ | |||||||

|

|

|

|

|

| ||

Q235 | B | 235 | 225 | 215 | 205 | ||

Alloy No | Grade | Tensile strength (Mpa) | Elongation after fracture (%) | ||||

Thickness (mm) | |||||||

| ≤16 | >16--40 | >40--60 | >60--100 | |||

≥ | |||||||

|

|

|

|

|

|

| |

Q235 | B | 375--500 | 26 | 25 | 24 | 23 | |

Usage & Applications of Angle Steel

According to the needs of different structures, Angle can compose to different force support component, and also can be the connections between components. It is widely used in various building structures and engineering structures such as roof beams, bridges, transmission towers, hoisting machinery and transport machinery, ships, industrial furnaces, reaction tower, container frame and warehouse etc.

Packaging & Delivery of Angle Steel

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

Production flow of Angle Steel

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

- Q: How do you connect two steel angles together?

- One common method to connect two steel angles together is through welding. Welding is the process of melting the edges of the angles and fusing them together using an electric arc or flame. This creates a strong and permanent connection between the two angles. Prior to welding, it is important to prepare the surfaces by cleaning them from any contaminants or rust. Additionally, aligning the angles properly and securing them in place with clamps or tack welds helps to ensure a precise and accurate connection. Another option to connect steel angles is through the use of bolts or screws. This method involves drilling holes through the angles and then using nuts and bolts or screws to fasten them together. It is crucial to select appropriate fasteners and ensure they are tightened securely to achieve a strong connection.

- Q: Can steel angles be used as reinforcements in concrete structures?

- Certainly! Reinforcements in concrete structures can include steel angles. Due to their exceptional strength and durability, steel angles are commonly utilized in concrete structures. These angles are placed within the concrete to provide additional support, preventing cracking or failure when subjected to heavy loads or stress. Steel angles offer versatility and are easily incorporated into the designs of various concrete structures, such as beams, columns, walls, and slabs. They are often combined with other reinforcement materials, like steel bars or mesh, to enhance the overall strength and stability of the concrete structure. The preference for steel angles arises from their ease of installation, cost-effectiveness, and ability to withstand the harsh environmental conditions typically encountered in construction projects.

- Q: What are the different types of steel angles used in structural engineering?

- There are several types of steel angles commonly used in structural engineering, including equal angles, unequal angles, L-shaped angles, and T-shaped angles. Each type has its own specific applications and structural purposes.

- Q: Are steel angles suitable for scaffolding?

- Certainly, scaffolding can indeed utilize steel angles. With their strength and durability, steel angles serve as an excellent option for bolstering hefty loads and ensuring stability at construction sites. By effortlessly connecting and assembling them, a steady structure for workers to reach elevated levels during construction or maintenance endeavors can be promptly established. Moreover, the versatility of steel angles permits diverse configurations and adjustments to cater to distinct project needs. Overall, steel angles are deemed as a dependable and frequently employed element within scaffolding systems.

- Q: Can steel angles be used in agricultural buildings?

- Yes, steel angles can be used in agricultural buildings. Steel angles are commonly used in construction due to their durability and structural strength. They can be used for framing, bracing, and reinforcing various parts of agricultural buildings such as roofs, walls, and support structures. Steel angles provide stability and resistance against external forces, making them suitable for the demanding environments often found in agricultural settings.

- Q: Can steel angles be used for shelving?

- Yes, steel angles can be used for shelving. Steel angles are commonly used in shelving systems due to their durability and strength. They provide sturdy support for shelves and can withstand heavy loads. Additionally, steel angles are versatile and can be easily customized to fit different shelving configurations. They are often used in industrial settings, warehouses, garages, and even in residential applications where a strong and reliable shelving solution is desired.

- Q: Are steel angles suitable for use in high-rise buildings?

- Yes, steel angles are suitable for use in high-rise buildings. Steel angles are commonly used as structural elements in high-rise buildings due to their excellent strength, durability, and versatility. They are able to withstand heavy loads and provide structural support, making them ideal for use in beams, columns, and bracing systems. Steel angles can be easily fabricated and installed, allowing for efficient construction processes. Additionally, steel angles can be designed in various sizes and shapes to meet specific structural requirements, providing flexibility in design and construction. Overall, steel angles are a reliable and cost-effective choice for high-rise buildings as they offer the necessary strength and stability required for such structures.

- Q: How do steel angles perform in terms of durability and longevity?

- Steel angles are known for their excellent durability and longevity. Due to their robust composition and resistance to corrosion, steel angles can withstand harsh environmental conditions, heavy loads, and extreme temperatures, making them highly durable. Moreover, their longevity is further enhanced by their ability to retain their structural integrity over prolonged periods without deteriorating. Overall, steel angles are a reliable and long-lasting choice for various construction and industrial applications.

- Q: What are the different types of steel angles used in transmission towers?

- In transmission tower construction, there are three primary types of steel angles commonly employed: equal angles, unequal angles, and back-to-back angles. Equal angles, denoted as L-shaped sections, possess equal sides. They serve as cross-arms in transmission towers, providing structural stability and support. These angles are well-suited for bearing horizontal loads and are frequently utilized in the middle and upper regions of the tower. Unequal angles, as indicated by their name, possess unequal sides. They are utilized in transmission towers to enhance strength and stability in areas where load distribution is uneven. The longer side of the unequal angle is typically positioned on the side requiring greater strength. These angles are commonly used in the lower sections of transmission towers. Back-to-back angles are created by joining two equal angles together, forming a singular section. They are employed in transmission towers to augment strength and rigidity. Back-to-back angles find application in areas with non-uniform load distribution or where the tower must support heavier loads. These angles are commonly found in the base sections of transmission towers. The selection of steel angles for transmission towers depends on several factors, including tower height, load requirements, and specific design considerations. Engineers meticulously analyze these factors to determine the most suitable type of steel angle for each tower section, ensuring overall stability and strength of the transmission tower structure.

- Q: How do steel angles perform under impact or dynamic loading conditions?

- Steel angles are known for their exceptional strength and durability, making them highly capable of withstanding impact or dynamic loading conditions. When subjected to sudden forces or dynamic loads, steel angles exhibit resistance to deformation, bending, and fracture, thanks to their high tensile and yield strengths. The shape of steel angles, with their L-shaped cross-section, adds to their structural integrity and ability to resist impact. The flanges of the angle distribute the load evenly, effectively transferring the forces to the supporting structure. This design feature allows steel angles to efficiently absorb and distribute the impact energy, reducing the risk of failure or structural damage. Steel angles also possess excellent fatigue resistance, enabling them to endure repeated or cyclic loading without weakening or experiencing fatigue failure. This is crucial in applications where dynamic or fluctuating loads are prevalent, such as bridges, cranes, machinery, and various structural components subject to vibrations or dynamic forces. Moreover, steel angles can be further enhanced through various techniques, such as heat treatment or alloying, to improve their impact resistance and toughness. These methods can increase the hardness and strength of the angle, making it even more capable of withstanding severe impact or dynamic loading conditions. Overall, steel angles are a reliable choice for applications involving impact or dynamic loading conditions. Their combination of high strength, structural integrity, and fatigue resistance allows them to perform exceptionally well under such circumstances, ensuring the safety and longevity of the structures they are incorporated into.

Send your message to us

GB Q235B high quality angle steel 20-250MM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords