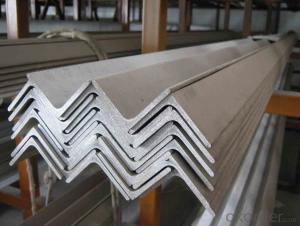

Angle steel High quality hot rolled GB Q235B 20-250MM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 6000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Angle Steel Details:

| Minimum Order Quantity: | 25mtons | Unit: | m.t. | Loading Port: | China Main Port |

| Supply Ability: | 80000-100000MTS/YEAR | Payment Terms: | TT or LC |

Product Description:

Specifications of Angle Steel

1. Invoicing on theoretical weight or actual weight as customer request

2. Length: 6m, 9m, 12m as following table

3. Sizes

Sizes: 25mm-250mm | ||

a*t | ||

25*2.5-4.0 | 70*6.0-9.0 | 130*9.0-15 |

30*2.5-6.6 | 75*6.0-9.0 | 140*10-14 |

36*3.0-5.0 | 80*5.0-10 | 150*10-20 |

38*2.3-6.0 | 90*7.0-10 | 160*10-16 |

40*3.0-5.0 | 100*6.0-12 | 175*12-15 |

45*4.0-6.0 | 110*8.0-10 | 180*12-18 |

50*4.0-6.0 | 120*6.0-15 | 200*14-25 |

60*4.0-8.0 | 125*8.0-14 | 250*25 |

5. Payment terms:

1).100% irrevocable L/C at sight.

2).30% T/T prepaid and the balance against the copy of B/L.

3).30% T/T prepaid and the balance against L/C

6.Material details:

Alloy No | Grade | Element (%) | |||||

C | Mn | S | P | Si | |||

|

|

|

|

|

|

| |

Q235 | B | 0.12—0.20 | 0.3—0.7 | ≤0.045 | ≤0.045 | ≤0.3 | |

|

|

|

|

|

|

| |

Alloy No | Grade | Yielding strength point( Mpa) | |||||

Thickness (mm) | |||||||

≤16 | >16--40 | >40--60 | >60--100 | ||||

≥ | |||||||

|

|

|

|

|

| ||

Q235 | B | 235 | 225 | 215 | 205 | ||

Alloy No | Grade | Tensile strength (Mpa) | Elongation after fracture (%) | ||||

Thickness (mm) | |||||||

| ≤16 | >16--40 | >40--60 | >60--100 | |||

≥ | |||||||

|

|

|

|

|

|

| |

Q235 | B | 375--500 | 26 | 25 | 24 | 23 | |

Usage & Applications of Angle Steel

According to the needs of different structures, Angle can compose to different force support component, and also can be the connections between components. It is widely used in various building structures and engineering structures such as roof beams, bridges, transmission towers, hoisting machinery and transport machinery, ships, industrial furnaces, reaction tower, container frame and warehouse etc.

Packaging & Delivery of Angle Steel

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

Production flow of Angle Steel

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

- Q: Bearing capacity of angle steel and channel steel

- According to the channel shape and can be divided into 4 kinds: cold bending equilateral channels, cold-formed non equilateral channel steel, cold rolled edge channels, the cold bending edge channels.According to the theory of steel structure, it should be stressed by the channel plate, that is to say, the channel should stand rather than lie prone.

- Q: Can steel angles be used for signage or billboards?

- Yes, steel angles can be used for signage or billboards. Steel angles provide a sturdy and durable support structure for the signage or billboard, ensuring it remains stable and secure. Additionally, steel angles can be easily customized and fabricated to meet specific design requirements, making them a versatile choice for signage applications.

- Q: Can steel angles be used in the construction of government buildings?

- Yes, steel angles can be used in the construction of government buildings. Steel angles are commonly used as structural components in building construction due to their strength and durability. They provide stability and support to the overall structure, making them suitable for use in government buildings, which often require robust and long-lasting construction materials. Additionally, steel angles can be easily fabricated and customized to meet specific design requirements, making them a versatile choice for various architectural and structural applications in government buildings.

- Q: What are the common applications of steel angles in the automotive industry?

- The automotive industry frequently relies on steel angles for a variety of purposes due to their versatility and strength. One specific use in this industry involves the construction of vehicle frames and chassis, where steel angles are commonly employed to ensure structural support and rigidity. This, in turn, guarantees the overall strength and stability of the vehicle. Another common application for steel angles is in the production of brackets and mounting components. These angles are utilized to securely attach various parts - such as engine mounts, suspension components, and exhaust systems - to the chassis of the vehicle. By doing so, steel angles contribute to the proper functioning and longevity of these components. Steel angles are also heavily involved in the creation of safety features within automobiles. For example, they are crucial in the construction of roll cages, which safeguard occupants in the event of a rollover or collision. Due to their exceptional strength and ability to absorb and distribute impact forces, steel angles are preferred for roll cages, ultimately enhancing the safety of the vehicle. Furthermore, steel angles have a wide range of applications in the design and production of various automotive accessories and components. They are commonly utilized as reinforcement in door panels, fenders, and bumpers, elevating the overall structural integrity of these parts. Additionally, steel angles are employed in the fabrication of trailer hitches, tow bars, and roof racks, providing robust and secure attachment points for towing and carrying heavy loads. To summarize, steel angles play a critical role in the automotive industry by offering structural support, facilitating secure connections, enhancing safety, and improving the overall performance and durability of vehicles and their components.

- Q: What are the different methods of connecting steel angles together?

- There are several different methods of connecting steel angles together, depending on the specific application and structural requirements. Some of the common methods include: 1. Welding: Welding is one of the most common and effective methods of connecting steel angles. It involves melting the edges of the angles and fusing them together using a welding electrode. This provides a strong and permanent connection. 2. Bolting: Bolting is another commonly used method to connect steel angles together. It involves using bolts, nuts, and washers to secure the angles in place. Bolting provides a strong connection that is easier to disassemble if needed. 3. Riveting: Riveting is a method that involves using metal pins called rivets to connect steel angles. It requires drilling holes in the angles and inserting the rivets, which are then hammered or pressed to create a permanent connection. 4. Adhesive bonding: Adhesive bonding is a method that involves using industrial adhesives to connect steel angles. It requires applying the adhesive to the surfaces of the angles and then pressing them together. Adhesive bonding provides a strong and durable connection that is also resistant to corrosion. 5. Mechanical connectors: Mechanical connectors, such as steel clips or brackets, can also be used to connect steel angles. These connectors are designed to provide a secure and rigid connection by clamping the angles together. It is important to choose the appropriate method based on factors such as the load-bearing requirements, structural design, and environmental conditions. Consulting with a structural engineer or a professional in the field is recommended to ensure the proper method is selected for the specific application.

- Q: Can steel angles be drilled or cut?

- Yes, steel angles can be drilled or cut using appropriate tools and techniques.

- Q: What are the fire resistance properties of steel angles?

- Steel angles, known as L-shaped metal bars, possess exceptional fire resistance properties. Their high melting point and inability to easily combust or support the spread of fire are due to the composition and structure of steel. In the event of a fire, steel angles maintain their structural integrity for an extended period, allowing occupants to evacuate and firefighters to control the situation. This fire resistance is attributed to steel's non-combustible nature and efficient heat dissipation. Furthermore, steel angles have low thermal conductivity, which prevents the rapid spread of fire and reduces the risk of structural failure. Consequently, fire-resistant building designs and constructions often incorporate steel angles as a reliable and safe option for structural support in fire-prone environments.

- Q: Are steel angles available in different colors?

- No, steel angles typically come in a standard metallic gray color. However, it is possible to apply various finishes or coatings to steel angles to achieve a different color or appearance. These finishes can include powder coating, paint, or galvanization, which may offer a range of colors to choose from. It is important to note that the availability of colors may vary depending on the specific manufacturer or supplier.

- Q: What is the maximum slope for a steel angle?

- The maximum slope for a steel angle depends on various factors such as the size, shape, and thickness of the angle. However, in general, steel angles are designed to withstand vertical loads and provide stability in structural applications. Therefore, the maximum slope for a steel angle is typically limited to angles less than 45 degrees. Going beyond this angle may compromise the structural integrity of the angle and increase the risk of failure. It is important to consult engineering codes, standards, and specifications to determine the specific maximum slope for a particular steel angle in a given application.

- Q: What is the weight of a steel angle?

- The weight of a steel angle depends on its dimensions and density. To calculate the weight, one needs to know the length, width, and thickness of the steel angle. By multiplying the volume of the angle (length x width x thickness) by the density of steel, one can determine its weight. The density of steel is typically around 7.85 grams per cubic centimeter. Therefore, the weight of a steel angle can be calculated using the formula: weight = volume x density.

Send your message to us

Angle steel High quality hot rolled GB Q235B 20-250MM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 6000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords