Garden Wpc Deck/Flooring Planks Made In China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Garden Wpc Deck/Flooring Planks Made In China

一.Product Description:

| Material | 60%-65% natural wood fiber |

| 30%-35% of eco-friendly HDPE materials | |

| 5% -10% Chemical additivel | |

| Size | 135X25mm,140X25mm,150*25mm,145*30mm,150*30mm |

| Design | Hollow decking |

| Technic | Extruded |

| Length | 3m/pc standard length, also from your required |

| Surface treament | Groove , Woodgrain, Flat, Embossing |

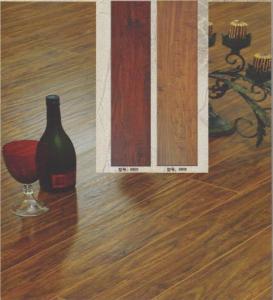

| Color available | Copper Brown, Light Brown, Black, Cedar, Coffee,Dark Grey, Silver Grey, Yellow, Red and Wood,etc. |

| ( we can adjust the new color according to the order requirement) | |

| Cerfiticate | ISO9001,CE, Microbiological testing ,TUV,ect |

| Lifetime | 25years |

| Package | pallet with PVC soft flim |

| Delivery time | 2 weeks(sometimes we have in store) |

| MOQ | 300SQ |

二.Technical Data

Slip resistance:

Boards of Techwoodn according to ASTM D2394-05. This is the best ranking for bare-foot slip resistance.

Weathering resistance:

Boards of Techwoodn have very low moisture uptake.This is key for mold and mildew resistance.

UV resistance:

4000 hours accelerated Xenon-arc Exposure,the Boards turned slightly more clear and colored.

Abrasion resistance:

The resistance to abrasion is similar to oak.

Fungus resistance:

Whatever fungus the wood composite is exposed to,it is extremely durable.

Moreover,aging test does not affect this durability.

三. FAQ

. What kinds of wpcproducts do you have?

We have wpc decking in different size, fence series (only wpc material or connect with aluminum profiles, decking tile series.

. Is it difficult to install the wpc board?

No, it is easy to install. Using the tool which you use to install the real wood. Fix the board on the substructure with clips.

. Can you stick the label with our logo on the boards?

Yes, please provide the label drawing, we can stick the customized label on the board.

. What documents are available?

A full range documents, including products pictures, installation guide and relative certificates can be provided; Further more, customs declaration is provided. This is an one-stop service for you.

四. More picture for your reference

- Q: what should you use on a cement floor that has been painted with paint. spray paint gloss finish or floor wax. ?

- you can get wax for concrete floors...Lowes, Home Depot...just ask them...you need a polisher (one of those rotary ones.)

- Q: I am looking at a home from 1939. i know asbestos was used from like the1970's back very often.i want to lay down different flooring in the kitchen,however i do now want to mess with the removal of the crap(asbestos)is there a way to put flooring down without having to get all this professional removal done. and no i don't want to mess with doing it myself either.

- If the floor is in good shape, and there no local ordinances about removing the previous tile why not. If there is asbestos in the flooring, which I doubt, It is safer to leave it where it is and seal it under a new floor. Pry up a corner and look to see how many layer you have though. It may be that things are getting kind of tall in that kitchen in relation to the adjacent floors. If there is damage in the old floor and gaps between tiles you will want a filler product and check to see how level the floor is too. You may have to level it if it has deformed appreciatively over the years. Check some of the DYI sites here on the web some have very good tutorials and product recommendations.

- Q: Ok, so this is my new Question from my old question, how do I do pelvic floor exercises.???

- The short answer is, act like you're holding in your urine (use the muscles you would normally use to stop the flow of urine). Do this for 15 seconds at a time, then release. Repeat this exercise often throughout the day.

- Q: Okay, I have been wanting to turn my garage into a dance studio for a while. I have checked in to marley flooring and it is so expensive. I don't want to get the 'home studio kit' and don't want wood flooring. So where can I find cheap marley flooring? Thanks :)

- There is no such thing a cheap marley and you cannot put marley directly on cement. Marley is meant to be put on top of a sub floor that is sprung or floating. Even the portable marley with the foam backing which is the most expensive one, has to be on top of a floor with some give and never cement. The only way to put a dance floor over cement is to isolate it from the cement by raising the floor up and using a floating floor or sprung floor. Then you put marley on top of that if you can afford it. You can however just dance on a wood floor as long as it is isolation from the cement floor and is sprung or floating.

- Q: Hi to tell you the truth I have Benny living in this apartment for 17 years since all my life but anyway I wanted to know what's the best flooring for a bedroom. Because it's time to change one but I don't like Carpet because of hard of cleaning the mess. No matter how much I tried to sweep vacuum or use special chemicals it was still dirty. I just want to know which is better wood, tile, vinyl any of those things. Thank you veery much!

- Wood flooring is always nice and so is tiling. But with any hard floor comes cold floors. You can purchase an area rug to put down by your bed so in the morning your feet don't get cold when getting out of bed.

- Q: What is the ceiling effect of the ceiling

- Both refer to some extreme reaction of the dependent variable. The ceiling effect refers to almost all of the dependent variables showing a high score or a high level; the floor effect is that the dependent variable almost always exhibits a low score or a low level. When this happens, to avoid the direct result of the extreme results attributed to the operation of independent variables, to carefully check the relationship between the task attributes and subjects, such as whether the task is too simple or too much of the subjects and so on

- Q: My old flooring has quarter round trim at baseboards. I want to install laminate flooring over old, do I HAVE to take up the quarter round? Is there some other trim that can go on the new flooring edges that butts up to the existing quarter round?

- No. Rip up the old quarter round. If you cannot get it up without damaging it, then just replace it. The laminate flooring should extend to about 1/4 of the wall, and that gap is covered by the quarter round. You do not want multiple runs of quarter round going around the room that would be just plain silly.

- Q: i live in canada and really like tatami. only one problem. are they like mats, or soft flooring, or hard flooring. basically is tatami flooring or just mats?? thanks!

- it's recommended that you also do not wear shoes on this flooring as it wears down the tatami mats quickly. Hope this helps!

- Q: Can you also give an example on what things are to be placed in a floor plan and floor finish plan.Thanks!

- Floor plan is the whole layout of the house from bird's eye view. Floor finish is what you use to make the floors look good.

- Q: How to clean the wood floor is the best cleaning

- My family directly with a broom sweep, and then drag a mop on it, solid wood flooring playing wax, strengthen the floor generally do not need, personal opinion, for reference only

Send your message to us

Garden Wpc Deck/Flooring Planks Made In China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords