Galvanized Welded Hex Wire Fence with Different Sizes

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Galvanized Welded Hex Wire Fence with Different Sizes

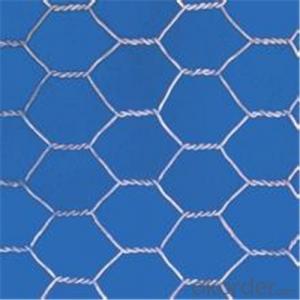

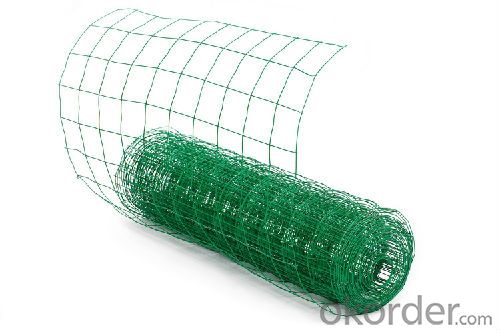

1. Structure of Galvanized Welded Hex Wire Fence with Different Sizes Description:

Galvanized Welded Hex Wire Fence with Different Sizes is make of Quality low carbon steel wire, stainless steel wire, aluminum alloy wire.Chain link fence with uniform mesh hole, flat surface, beautiful apprearance, great corrosion resistance, long service life. Does not dag or roll up at the bottom.

Galvanized Welded Hex Wire Fence with Different Sizes is mainly used in feeding chickens, ducks, geese, rabbits, zoo fence, machinery and equipment protection, highway guardrail, sports fence, the road green belt protection, storage, security and reinforcement materials.

2. Main Features of Galvanized Welded Hex Wire Fence with Different Sizes :

• Firm structure,

• Uniform opening

• Beautiful shape

• Simple weaving

• Good anti-corrosion

• Practical use

3. Galvanized Welded Hex Wire Fence with Different Sizes Images

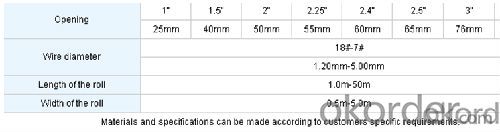

4. Galvanized Welded Hex Wire Fence with Different Sizes Specification

5. FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Galvanized Welded Hex Wire Fence ?

As a profession supplier ,we are engaged in the production and trade of wire mesh, like Chain link Wire Mesh, hot rolled steel plate/coil, cold rolled steel coil, gi steel coil, pp gi coil, corrugated sheet, wire rod and so on. We have established business relationships with clients in the Southeast Asia, South Asia, North America, and many other countries and regions. Our goal is to provide all our customers with qualified and low-cost steel products.

②The reason why you choose us?

· Diversification of products

. Professional sales team

· Industry experience over 15 years

· Shipment of goods -More than 50 countries worldwide

· We have the most convenient transport and prompt delivery

· We offer competitive price with best service

· We have win high reputation based on best quality products

③How long can we receive the product after purchase?

In the purchase of Galvanized Welded Hex Wire Fence within three working days, we will arrange the factory delivery as soon as possible. The pacific time of receiving is related to the state and position of customers. Commonly 15 to 20 working days can be served.

- Q: What are the benefits of using steel wire mesh in the automotive manufacturing industry?

- There are several benefits of using steel wire mesh in the automotive manufacturing industry. Firstly, steel wire mesh provides excellent strength and durability, making it suitable for various applications such as reinforcing components, including bumpers and body panels, to enhance overall vehicle safety. Secondly, its flexibility allows for easy customization and shaping, enabling manufacturers to meet specific design requirements. Additionally, steel wire mesh is resistant to corrosion, ensuring longevity and reliability even in harsh environments. Lastly, its open structure allows for improved ventilation and airflow, making it ideal for applications such as air filters and engine components. Overall, steel wire mesh proves to be a versatile and advantageous material choice in the automotive manufacturing industry.

- Q: How is the strength of steel wire mesh determined?

- The strength of steel wire mesh is determined through various testing methods. One common method is the tensile strength test, where a sample of the steel wire mesh is subjected to a gradually increasing load until it breaks. The force required to break the sample is then measured, and this provides an indication of the tensile strength of the wire mesh. Another important factor in determining the strength of steel wire mesh is the wire diameter. Thicker wires generally have higher strength compared to thinner wires. The wire diameter can be measured using a micrometer or a gauge. The type of steel used in the wire mesh also affects its strength. Different types of steel have varying tensile strengths, which can be determined through material testing. Common types of steel used in wire mesh include carbon steel, stainless steel, and galvanized steel. Additionally, the mesh opening size and the weaving pattern of the wire mesh can impact its strength. Smaller mesh openings and tighter weaves generally result in stronger wire mesh. It is important to note that the strength of steel wire mesh can vary depending on the manufacturing process and quality control measures. To ensure accurate strength determination, it is recommended to refer to industry standards and specifications, and to rely on certified testing laboratories for accurate and reliable results.

- Q: How is steel wire mesh used in the agriculture industry?

- Steel wire mesh is commonly used in the agriculture industry for various purposes such as fencing, animal enclosures, and crop protection. It provides a durable and secure barrier to keep animals within a designated area or to protect crops from pests and other external threats. Additionally, steel wire mesh can be used to create trellises for supporting climbing plants or as a reinforcement material for agricultural structures.

- Q: What are the electrical resistance properties of steel wire mesh?

- Steel wire mesh typically has low electrical resistance properties. This is due to the fact that steel is a good conductor of electricity. When a current flows through the steel wire mesh, the electrons can easily move through the material, resulting in low resistance. However, the specific electrical resistance properties can vary depending on factors such as the thickness of the wire and the size of the mesh openings. Generally, steel wire mesh is considered to be a good conductor of electricity, making it suitable for applications where electrical conductivity is required, such as in electrical grounding systems or in electrical circuits.

- Q: Can steel wire mesh be used for gabion terraces?

- Yes, steel wire mesh can be used for gabion terraces. Gabion terraces are structures that are used for erosion control and landscaping purposes, and they are typically made by filling wire mesh baskets with stones or rocks. Steel wire mesh is a common material used for these baskets as it provides strength and durability to withstand the weight and pressure of the fill material. Additionally, steel wire mesh is resistant to corrosion, which is important for structures that are exposed to outdoor elements. Overall, steel wire mesh is a suitable choice for constructing gabion terraces due to its stability, strength, and longevity.

- Q: What are the standard sizes of steel wire mesh?

- The standard sizes of steel wire mesh vary depending on the application and industry. However, some common standard sizes include 4x8 feet, 5x10 feet, and 6x12 feet. Additionally, wire mesh is available in various wire diameters and mesh opening sizes to suit specific needs and requirements.

- Q: How is steel wire mesh measured?

- Steel wire mesh is typically measured in terms of its mesh count or mesh size. The mesh count refers to the number of openings or spaces per linear inch in both the horizontal and vertical directions. The mesh size, on the other hand, represents the diameter of the wire used to create the mesh. Both measurements are crucial in determining the strength, durability, and filtering capabilities of the steel wire mesh.

- Q: Can steel wire mesh be used for food processing?

- Yes, steel wire mesh can be used for food processing. Steel wire mesh is a durable and versatile material that can be easily cleaned and sanitized, making it suitable for use in various food processing applications. It is commonly used for sieving, filtering, and straining purposes in industries such as baking, brewing, dairy, and meat processing. The small openings in the mesh allow for efficient separation of solids from liquids or for the removal of impurities. Additionally, steel wire mesh can withstand high temperatures and is resistant to corrosion, making it a reliable choice for food processing environments. However, it is important to ensure that the steel wire mesh used for food processing meets food safety regulations and is made from stainless steel or other food-grade materials to prevent any contamination risks.

- Q: Is steel wire mesh suitable for marine or coastal applications?

- Yes, steel wire mesh is suitable for marine or coastal applications. It is highly durable and resistant to corrosion, making it ideal for withstanding the harsh conditions of saltwater and coastal environments. Additionally, steel wire mesh provides excellent strength and stability, making it an effective material for various marine applications such as seawalls, fish cages, and boat docks.

- Q: Is steel wire mesh suitable for HVAC applications?

- Yes, steel wire mesh is suitable for HVAC applications. It is commonly used in HVAC systems for air filtration, ductwork reinforcement, and protection against debris. Steel wire mesh offers durability, high strength, and excellent corrosion resistance, making it an ideal choice for HVAC applications.

Send your message to us

Galvanized Welded Hex Wire Fence with Different Sizes

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches