Low carbon steel expanded metal mesh (manufacturer )

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

expanded metal panel

1.expanded metal concept: expanded metal, also called tensile net, punching shear nets, diamond metal, perforated plate, heavy expaned metal sheet...

expanded metal sheet is the sheet metal after punching shear with punching shear machine , tensile and become with diamond mesh of sheet material network products.

Special designs or size is also available at customers' request!

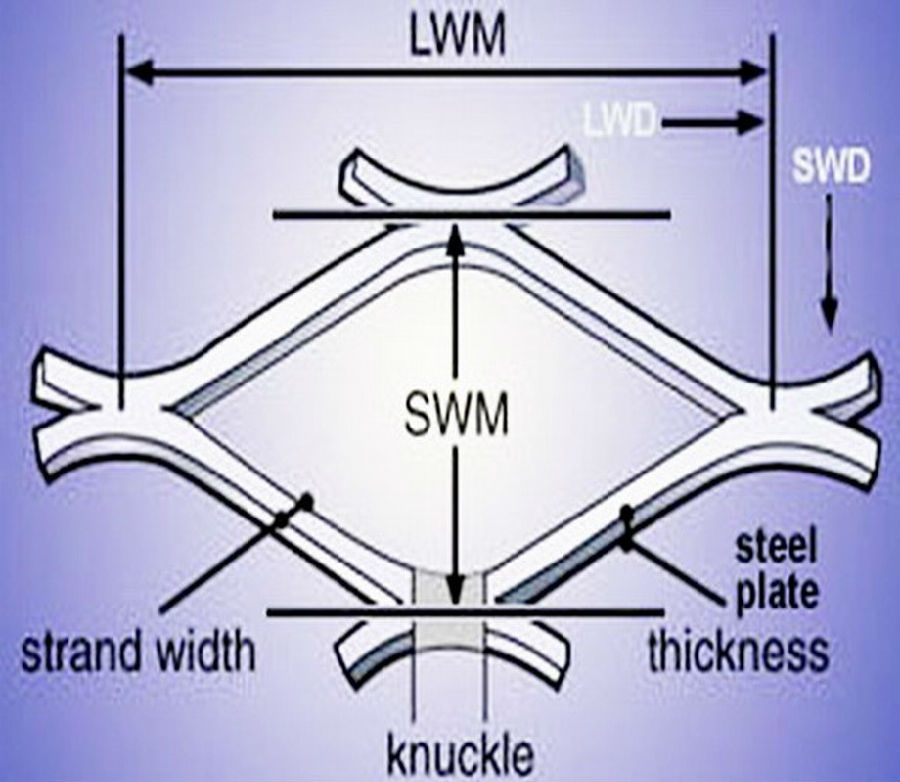

The diagramming of the expanded mesh sheet. We can make the 3m width and 10mm plate thickness expanded mesh.

SWD- short way diamond

LWD- long way diamond

BOND- where two strands intersect

STRAND WIDTH- length of the metal used to produce one strand

STRAND THICKNESS- guage thickness

LWM (WIDTH)- mesh sheet size, the distance of lwd direction

SWM(LENGTH)- mesh sheet size, the distance of swd direction

2.Material: We can supply expanded mesh in a variety of materials including aluminum, platinum, brass, steel, low carbon steel,copper, nickel plates,

stainless steel, and is usually purchased from steel mills in Tianjin.

3.Packing: The packing usually is pallet or wooden box to avoid damage or deformation to the aluminum product.

Of course, we can packaging according to your requirement.

4.Application: Used with concrete in buildings and construction, maintenance of equipments, making of arts and crafts, covering screen for first class sound case. Also fencing for super highway, studio, highway. Heavy expanded metal can be used as step mesh of oil tanks, working platform, corridor and walking road for heavy model equipment,

boiler, petroleum and mine well, automobile vehicles, big ships. Also serve as reinforcing bar in construction, railway and bridges. widely used in the core of filter, medicine, filtering, breeding, battery, mechanical protecting, making the crafts, the meshes for the high-grade sound box, decoration, the seating for children, baskets, etc.

- Q: Can steel wire mesh be used for architectural purposes?

- Yes, steel wire mesh can be used for architectural purposes. It offers various advantages such as strength, durability, and flexibility in design. Steel wire mesh can be used for façade cladding, partitions, ceilings, and other architectural elements, providing both aesthetic appeal and functional benefits.

- Q: Can steel wire mesh be used for privacy screens?

- Yes, steel wire mesh can be used for privacy screens. Steel wire mesh is a versatile material that can provide both security and privacy. It can be used to create barriers and enclosures that obscure the view from the outside, making it an ideal choice for privacy screens. Steel wire mesh is strong and durable, making it suitable for outdoor applications. It can be customized to various sizes and shapes, allowing for flexibility in design. Additionally, steel wire mesh can be combined with other materials such as wood or vinyl to enhance privacy and aesthetic appeal. Overall, steel wire mesh is a reliable and effective option for creating privacy screens.

- Q: What are the different wire joining methods used in steel wire mesh?

- There are several different wire joining methods used in steel wire mesh, each with its own advantages and applications. 1. Welding: Welding is one of the most common methods used for joining steel wire mesh. It involves melting the wires at their intersection points and then fusing them together. This creates a strong bond between the wires, making the mesh highly resistant to pulling and bending forces. Welded wire mesh is commonly used in construction, concrete reinforcement, and industrial applications. 2. Weaving: Weaving is another popular method for joining steel wires in a mesh pattern. It involves interlacing the wires in an over and under pattern to create a stable and flexible structure. Woven wire mesh has excellent strength and durability, making it suitable for various applications such as filtration, security, and animal enclosures. 3. Crimping: Crimping involves bending the wires at their intersection points to create a mechanical bond. This method is often used for lighter weight wire mesh and provides good stability and flexibility. Crimped wire mesh is commonly used in applications such as window screens, sieves, and decorative purposes. 4. Soldering: Soldering is a process that involves melting a metal alloy to join the wires together. This method is typically used for fine wire mesh, where welding may cause damage or distortion. Soldered wire mesh is commonly used in electronics, jewelry making, and fine arts. 5. Mechanical fasteners: In some cases, mechanical fasteners such as clips, clamps, or hooks are used to join the wires in a steel wire mesh. This method allows for easy assembly and disassembly of the mesh, making it suitable for temporary or adjustable applications. Each wire joining method has its own strengths and weaknesses, and the choice of method depends on factors such as the desired strength, flexibility, durability, and the specific application requirements.

- Q: Can steel wire mesh be used for window and door screens?

- Certainly, window and door screens can utilize steel wire mesh. Steel wire mesh, a robust and enduring material, is widely employed in numerous applications, including window and door screens. It effectively blocks insects and undesirable elements while permitting the flow of air and light. Steel wire mesh screens are resistant to corrosion and can endure severe weather conditions, rendering them suitable for both indoor and outdoor purposes. Furthermore, these screens come in various mesh sizes and thicknesses, enabling you to select the most suitable option based on your specific requirements.

- Q: What are the advantages of using steel wire mesh in construction?

- There are several advantages of using steel wire mesh in construction. Firstly, steel wire mesh provides high tensile strength and durability, making it suitable for reinforcing concrete structures and enhancing their structural integrity. Additionally, steel wire mesh offers excellent resistance to corrosion, ensuring the longevity of the construction project. It also provides a cost-effective solution due to its ease of installation and low maintenance requirements. Moreover, steel wire mesh allows for better load distribution and reduces cracking in concrete, resulting in improved overall performance. Lastly, steel wire mesh is highly versatile, allowing it to be customized to fit various construction needs, such as reinforcing walls, slabs, and foundations.

- Q: Galvanized welded wire mesh and hot galvanized steel wire mesh What is the difference

- To extend the life of the building, but also reduce maintenance costs. In the integrity, insulation, durability and seismic performance has a very high superiority, energy saving effect is good.

- Q: Steel skeleton plastic pipe and steel mesh skeleton plastic pipe is the difference between what

- Another reason, the interface is not in place, in the water for a long time soaking, the pipe and the pipe part of the contact surface separation.

- Q: What are the benefits of using steel wire mesh in the chemical manufacturing industry?

- There are multiple advantages to utilizing steel wire mesh within the chemical manufacturing sector. To begin with, steel wire mesh possesses exceptional strength and durability. Its ability to endure high temperatures, corrosive chemicals, and extreme pressures makes it an ideal choice for chemical manufacturing procedures that involve harsh conditions. As a result, the equipment and infrastructure used within chemical plants are guaranteed to be safe and long-lasting. Moreover, steel wire mesh provides superior resistance against chemical reactions. It does not react with most chemicals, making it an outstanding option for containing and transporting corrosive substances. This reduces the possibility of contamination and ensures the integrity of the manufacturing process. Furthermore, steel wire mesh offers excellent filtration capabilities. By weaving it into various mesh sizes, precise filtration of different chemical substances becomes possible. This plays a crucial role in maintaining the purity and quality of products, while also preventing blockages in pipes and equipment. Additionally, steel wire mesh is highly versatile and can be customized to meet specific requirements. It can be fabricated into different shapes, sizes, and configurations to suit the unique needs of various chemical manufacturing processes. This flexibility allows for the creation of efficient and effective systems for storing, separating, and handling chemicals. Moreover, steel wire mesh requires relatively low maintenance compared to other materials. It can be easily cleaned and does not necessitate frequent replacement, reducing downtime and overall operational costs. As a result, it proves to be a cost-effective choice for the chemical manufacturing industry. Lastly, steel wire mesh is environmentally friendly. It can be recycled and reused, minimizing waste and contributing to sustainable practices. This aligns with the increasing emphasis on sustainability and responsible manufacturing within the chemical industry. In conclusion, the utilization of steel wire mesh within the chemical manufacturing industry offers various benefits, including its strength and durability, resistance to chemical reactions, filtration capabilities, versatility, low maintenance requirements, and environmental friendliness. These advantages make steel wire mesh an invaluable material for ensuring the safety, efficiency, and sustainability of chemical manufacturing processes.

- Q: How is steel wire mesh used in the aviation industry?

- Steel wire mesh is used in the aviation industry for various applications, including reinforcing composite materials, providing structural support in aircraft panels, protecting sensitive components from debris, and enhancing the durability of aircraft parts.

- Q: Can steel wire mesh be used in marine environments?

- Indeed, the utilization of steel wire mesh is viable within marine environments. Renowned for its exceptional robustness and longevity, steel proves to be a fitting option for maritime purposes, particularly when the mesh must endure arduous circumstances encompassing saltwater, turbulent waves, and corrosion. Furthermore, steel wire mesh effectively safeguards against marine creatures and debris, rendering it widely employed in marine construction, fishing nets, and aquaculture systems. Nevertheless, to bolster its efficiency and endurance amid marine settings, it is advisable to employ stainless steel wire mesh, given its unparalleled resistance to corrosion in comparison to alternative steel varieties.

Send your message to us

Low carbon steel expanded metal mesh (manufacturer )

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords