Galvanized Welded Security Fence

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

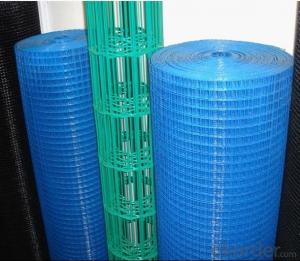

Welded wire mesh security fence was first developed in Europe where it has almost completely

replaced chainlink fence for perimeter barrier security. Today, European style welded security

fence is made here in Anping China, for more than 10 years experience of high quality, marine

grade welded wire mesh products

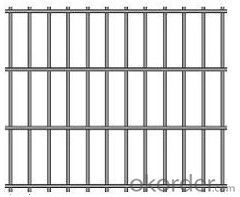

Galvanized Welded Security Fence is suitable for applications that have a strong need for

security. Possible applications include, airports, schools, power plants, hospitals and

anywhere that security with visibility are primary objectives.

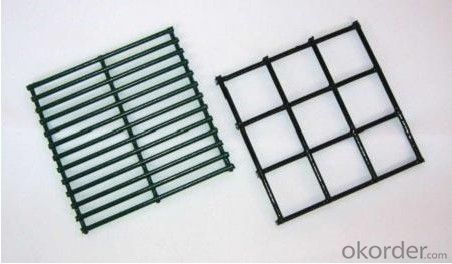

Galvanized Welded Security Fence:Features

Its durability and resistance characterize the easy-to-install Fiesta Design.

This particular sturdiness is due to the choice of the best materials and the use of modern

fastening systems with special U-shapes clamping strips. Thus, the Fiesta Design is the type

most often sold in this product segment and should be given first priority, if very strong

needs for security must be satisfied.

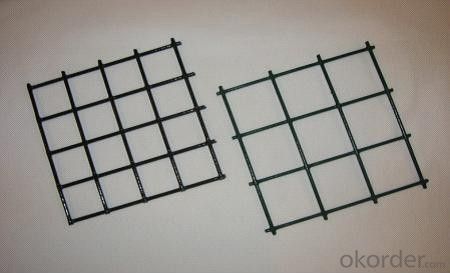

Mesh Specification:

Recommended Specifications based on our experience:

1/2" x 3" (8 and 10.5 gauge) and 2" x 2" (6 and 8 gauge) for security application

1.5" x 1.5 " and 2" x 2" (light gauge available in rolls) for Basic Perimeter Applications

6" x 2" (6 gauge) available in panels for Decorative Fence Applications

10" x 1.8" (6 and 4 gauge) for Decorative Fence Applications

- Q: On the issue of their own screen printing

- Printed clothes must first have a printed version of the screen, clothing version with 120 or 130 mesh screen to do, with the version, scraper, ink, you can start printing color clothes need color, only one color

- Q: What are the reasons for the hair making of the screen plate?

- The tension of the screen is a little bit (generally if the fingerprints, the recommended tension of 19 or so.

- Q: How to get the correct fishing wire

- stroked the net, in the clean concrete on the grass and other things slowly removed, and then re-network when the network as a stroke when the knot again, and then you can then the next network.

- Q: The difference between screen printing characteristics

- But also in the ultra-small, ultra-high precision items on the printing, and can also be printed on the surface or spherical, this printing method has great flexibility and wide applicability.

- Q: Screen printing and screen printing plate on the photosensitive material What are the requirements

- posters, business cards, binding cover, product signs and printing and dyeing textile and other silk screen pollution process first plate production The use of ink in the developer is the production of ink bucket cleaning is to produce cleaning waste or waste wipe

- Q: How to clean the screen plate

- Directly with tap water rushed, and can be used with a cloth or soft brush brush. That the white mortar is water-based, then your screen board must also be water-based, so the fastest wash with tap water, the cost is the lowest, water-based stencil is not afraid of water, rest assured that red will not rot, unless you in the water Plus a release agent and the like. (But the water-based screen in the prepress are generally on the curing agent, or else is not easy to wash easily)

- Q: Screen printing ink firmness problem

- If it is PVC tablecloth, you can try to corona the first surface of the printing process, so that the surface tension higher (recommended to 55 - 60 dyne), and then see if there is improvement.

- Q: How to make screen printing layout smooth

- You use the water-based screen version, or oily screen version. Oily general mesh is more dense. Sensitive plastic easy to have static electricity. So the glue can not play too thick. The choice of sensitive adhesive is also important,

- Q: What are the characteristics of screen printing?

- Screen printing is widely used in China's electronics industry, ceramic decals industry, textile printing and dyeing industry and packaging and decoration, advertising, posters and other industries, as the screen printing is much more than other printing methods have many unique advantages.

- Q: What is the principle of screen printing?

- The definition of printing: the text / graphics transferred to the substrate on the method called printing.

Send your message to us

Galvanized Welded Security Fence

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords