Hot Rolled Constructional U Beam Steel Channel Steel

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4000 PCS

- Supply Capability:

- 40000 PCS/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Hot Rolled Constructional U Beam Steel Channel Steel Details

Standard: | ASTM,GB,JIS | Dimensions: | 75*40-150*75mm | Grade: | q235 |

Place of Origin: | Hebei China (Mainland) | Brand Name: | Huikun | Material | S400 A36,Q235 |

Shape: | U Channel | Application: | bridge,construction ,buildings | Perforated Or Not: | Not Perforated |

Packaging & Delivery

Packaging Detail: | seaworthy export packing |

Delivery Detail: | 30days after getting l/c or t/t advance |

Hot Rolled Constructional U Beam Steel Channel Steel Specifications

Material :S400 A36,Q235

Size: 75*40mm-150*75 mm

Application: construction,bridge,building

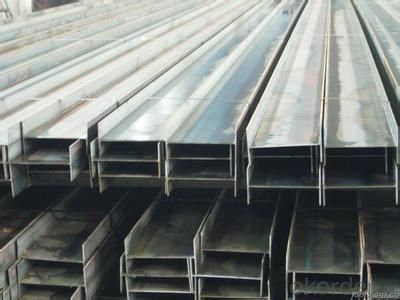

Hot Rolled Constructional U Beam Steel Channel Steel Pictures

- Q: Do steel channels have any specific safety considerations?

- Yes, steel channels have specific safety considerations that need to be taken into account. These include ensuring proper installation to prevent structural failure, regular inspection for signs of corrosion or damage, and implementing appropriate measures to prevent trips, slips, and falls when working around or on steel channels.

- Q: Two floors of shops, exterior wall hanging marble, I would like to ask the general keel, channel, angle steel with what kind of specifications? Is the angle iron L30*3 channel 6.3 OK? Do keel labour contractor, how much is the market price? The older generation with the experience helped! Thank you

- Conventional channel steel has 10#. 8#. 6.3 of the connection length, spacing, and various loads are very large. The angle iron is usually 5#4mm or 5mm and has to be calculated. Generally, it is accessible.

- Q: After the type of channel is not marked A or B, which shall be calculated?

- Channel steel is a kind of carbon structural steel used for construction and machinery. It is a complex section steel. Its cross section has a groove shape. Channel steel is mainly used in building structure, curtain wall engineering, mechanical equipment and vehicle manufacturing, etc.. In use, it requires better welding, riveting performance and comprehensive mechanical properties. The raw material steel billet for channel steel is carbon or low alloy steel billets with a carbon content of not more than 0.25%. The specification of channel steel is expressed by the height of the waist (H) * leg width (b) * waist thickness (d), such as 100*48*5.3, which means that the waist height is 100 mm, the width of the leg is 48 mm, and the thickness of the channel is 5.3 mm, or 10# channel. The same height of the channel, if there are several different leg width and waist thickness, also need to add a, B, C on the right side of the model to distinguish, such as 25#a, 25#b, 25#c and so on. In general, according to the model a, B, C order, its thickness (or intensity) increased in turn

- Q: What are the different loadings that steel channels can withstand?

- Steel channels can withstand a wide range of loadings, making them a versatile and reliable structural component. The specific loadings that steel channels can withstand depend on various factors, including the type and grade of steel, the size and shape of the channel, and the design of the overall structure. Steel channels are commonly used in construction and engineering applications to provide support and stability. They can withstand both static and dynamic loadings, which include dead loads, live loads, and environmental loads. Dead loads refer to the weight of the structure itself, including the weight of the steel channels and any other components or materials. Steel channels are designed to bear this constant load without deformation or failure. Live loads are temporary loads that can vary in magnitude and location. These loads include the weight of people, furniture, equipment, and other transient forces. Steel channels are designed to support these loads and distribute them effectively to other structural members. Environmental loads include wind loads, snow loads, and seismic loads. Steel channels are designed to resist these external forces and maintain the structural integrity of the building or structure. Wind loads can exert significant pressure on the channels, especially on tall or exposed structures. Snow loads can accumulate and add weight to the structure, which the steel channels must be able to support. Seismic loads refer to the forces generated during an earthquake, and steel channels are designed to withstand these dynamic loads and prevent the structure from collapsing. In addition to these common loadings, steel channels can also withstand other specialized loadings, such as impact loads, vibration loads, and thermal loads. Impact loads can occur due to accidental collisions or sudden impact events and require steel channels to have high strength and toughness. Vibration loads can result from machinery or equipment operation and require steel channels to have good fatigue resistance. Thermal loads can cause expansion and contraction of the steel channels due to temperature changes, and they must be designed accordingly to prevent failure. Overall, steel channels have a high load-bearing capacity and can withstand a wide range of loadings, making them suitable for various structural applications in construction, engineering, and industrial sectors.

- Q: Can steel channels be recycled?

- Indeed, it is possible to recycle steel channels. Steel, being a remarkably recyclable substance, can be reused indefinitely without compromising its qualities or durability. Once steel channels have served their purpose, they can be gathered, organized, and transported to recycling centers. The recycling procedure entails melting the steel channels to eliminate impurities, subsequently transforming the liquefied steel into fresh channels or alternative steel commodities. By engaging in this recycling process, not only are we conserving natural resources, but we are also diminishing the energy consumption and emissions connected to the production of new steel. Consequently, recycling steel channels represents an environmentally conscious decision that contributes to the establishment of a more sustainable future.

- Q: What are the different cutting techniques for steel channels?

- There are several cutting techniques for steel channels, including manual cutting with a hacksaw or a cutting torch, mechanical cutting with a bandsaw or a circular saw, and CNC plasma cutting. Each technique has its advantages and is selected based on factors such as the thickness and shape of the steel channel, precision requirements, and production volume.

- Q: How do steel channels contribute to the stability of a structure during hurricanes?

- The stability of a structure during hurricanes is greatly improved by the presence of steel channels. These channels possess exceptional strength and can bear heavy loads, which is why they are widely used in the construction industry to provide support and reinforcement. During hurricanes, when strong winds and intense forces assail a building, the steel channels effectively distribute these forces evenly throughout the structure. This prevents the formation of stress points and reduces the probability of structural failure. Additionally, steel channels are often incorporated into the framework of walls, roofs, and floors in a building. By doing so, they create a rigid structure that enhances overall stability. This rigidity enables the building to withstand the lateral forces and uplift pressures generated by hurricane winds. By resisting these forces, the steel channels minimize the risk of the structure collapsing or sustaining severe damage during a hurricane. Moreover, steel channels can be strategically placed in critical areas within a building to reinforce specific regions that are susceptible to wind and storm damage. A prime example of this is the reinforcement of window and door openings, which are particularly vulnerable to wind pressure. By installing steel channels around these openings, the structure becomes more resistant to the uplift and inward forces caused by high-speed winds. This reduces the likelihood of these openings being blown out or compromised. Furthermore, steel channels possess remarkable durability and resistance to corrosion, which makes them ideal for withstanding the adverse environmental conditions associated with hurricanes. Unlike other construction materials, steel channels do not deteriorate or weaken when exposed to moisture, saltwater, or high humidity levels. This longevity ensures that the structural integrity of the building remains intact, even after multiple hurricane events. In conclusion, the presence of steel channels is of utmost importance in enhancing the stability of a structure during hurricanes. Their exceptional strength, load-bearing capacity, rigidity, and resistance to environmental conditions make them an essential component in the construction of hurricane-resistant buildings. By effectively distributing forces, reinforcing critical areas, and maintaining their structural integrity, steel channels play a pivotal role in safeguarding structures and their occupants from the destructive forces of hurricanes.

- Q: Can steel channels be used for window and door frames?

- Certainly! Window and door frames can indeed utilize steel channels. With their strength and durability, steel channels offer ideal structural support for windows and doors. They not only bolster the stability and long-lasting nature of the frames but also fortify them against external forces like wind and impact. Furthermore, steel channels possess the flexibility to be tailored and manufactured to fit specific window and door dimensions. This adaptability renders them an excellent option for diverse architectural designs and applications.

- Q: How are steel channels used in structural applications?

- Steel channels are widely used in structural applications due to their excellent strength and versatility. They are commonly used in the construction industry for supporting heavy loads and providing structural integrity to buildings, bridges, and other infrastructures. One of the main applications of steel channels is in the framing of buildings. They are often used as beams or columns to support the weight of floors, walls, and roofs. Steel channels are chosen for these applications because they can withstand a significant amount of load without deforming or collapsing. In addition to building frames, steel channels are also used for bracing and reinforcing structures. They can be used as diagonal braces to provide lateral stability and prevent the structure from swaying or collapsing under wind or seismic forces. Steel channels are also utilized as reinforcement in concrete structures, such as retaining walls and foundations, to enhance their strength and durability. Steel channels are also employed in the manufacturing of machinery and equipment. They provide a stable and rigid framework for heavy machinery, allowing them to operate smoothly and efficiently. In this context, steel channels are often used as support beams, frames, or structural components in various industrial applications. Furthermore, steel channels find application in the transportation industry. They are used in the construction of bridges and overpasses, where their high strength and load-bearing capacity are essential for safely carrying vehicles and pedestrians. Steel channels are also utilized in the manufacturing of railway tracks and tramways, providing a durable and stable foundation for the transportation system. Overall, steel channels play a crucial role in structural applications by providing strength, stability, and durability to various types of constructions. Their versatility and ability to withstand heavy loads make them a preferred choice in the construction, manufacturing, and transportation industries.

- Q: Can steel channels be used for equipment racks?

- Yes, steel channels can be used for equipment racks. Steel channels provide a sturdy and durable framework that can support heavy equipment and provide excellent structural integrity for equipment rack installations.

Send your message to us

Hot Rolled Constructional U Beam Steel Channel Steel

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4000 PCS

- Supply Capability:

- 40000 PCS/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords