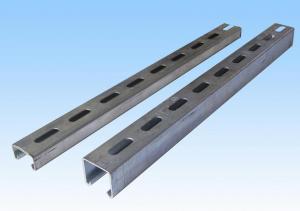

Channel Steel Galvanized for House, Wall, Ceiling

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

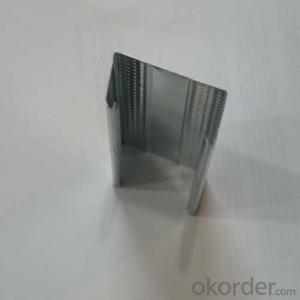

C Channel steel bar

Material: Q195Q235Q345

Size: 10-300*0.5-6.0mm

Finished: Black, Galvanized

C Channel Steel Bar

| Tianjin Jujin Industry and Trading Co.,Ltd | |||||

| Dafengdui Village,Dafengdui Town,Jinghai Country,Tianjin City,China | |||||

| Tel:+86-22-68661881 Fax:+86-22-68663603 | |||||

| Country of Origin:China | |||||

| Tolerance:Accroding to clients'requirements | |||||

| Delivery time:7-25 days | |||||

| Payment term:L/C or T/T | |||||

| Packing:Mills Standard Export Strong Packing in Bundles | |||||

| Details Products Description | |||||

| C channel steel | |||||

| Material | Specificationmm | Thicknessmm | Weightkg/m | ||

| h | b | a | |||

| Q195-Q235 Q345 | 80 | 50 | 20 | 2.25 | 3.886 |

| 80 | 50 | 20 | 2.5 | 4.318 | |

| 80 | 50 | 20 | 2.75 | 4.749 | |

| 80 | 50 | 20 | 3 | 5.181 | |

| 100 | 50 | 20 | 2.25 | 4.239 | |

| 100 | 50 | 20 | 2.5 | 4.71 | |

| 100 | 50 | 20 | 2.75 | 5.181 | |

| 100 | 50 | 20 | 3 | 5.652 | |

| 120 | 50 | 20 | 2.25 | 4.592 | |

| 120 | 50 | 20 | 2.5 | 5.103 | |

| 120 | 50 | 20 | 2.75 | 5.613 | |

| 120 | 50 | 20 | 3 | 6.123 | |

| 140 | 60 | 20 | 2.5 | 5.888 | |

| 140 | 50 | 20 | 2.5 | 5.495 | |

| 140 | 60 | 20 | 3 | 7.065 | |

| 140 | 50 | 20 | 3 | 6.594 | |

| 160 | 50 | 20 | 2.5 | 5.888 | |

| 160 | 60 | 20 | 2.5 | 6.28 | |

| 160 | 70 | 20 | 2.5 | 6.673 | |

| 160 | 50 | 20 | 3 | 7.065 | |

| 160 | 60 | 20 | 3 | 7.458 | |

| 160 | 70 | 20 | 3 | 7.536 | |

| 180 | 50 | 20 | 2.5 | 6.28 | |

| 180 | 60 | 20 | 2.5 | 6.673 | |

| 180 | 70 | 20 | 2.5 | 7.065 | |

| 180 | 80 | 20 | 2.5 | 7.458 | |

| 180 | 50 | 20 | 3 | 7.536 | |

| 180 | 60 | 20 | 3 | 8.007 | |

| 180 | 70 | 20 | 3 | 8.478 | |

| 180 | 80 | 20 | 3 | 8.949 | |

| 200 | 50 | 20 | 2.5 | 6.673 | |

| 200 | 60 | 20 | 2.5 | 7.065 | |

| 200 | 70 | 20 | 2.5 | 7.458 | |

| 200 | 80 | 20 | 2.5 | 7.85 | |

| 200 | 50 | 20 | 3 | 8.007 | |

| 200 | 60 | 20 | 3 | 8.478 | |

| 200 | 70 | 20 | 3 | 8.949 | |

| 200 | 80 | 20 | 3 | 9.42 | |

| 220 | 50 | 20 | 2.5 | 7.065 | |

| 220 | 60 | 20 | 2.5 | 7.458 | |

| 220 | 70 | 20 | 2.5 | 7.85 | |

| 220 | 80 | 20 | 2.5 | 8.243 | |

| 220 | 50 | 20 | 3 | 8.478 | |

| 220 | 60 | 20 | 3 | 8.949 | |

| 220 | 70 | 20 | 3 | 9.42 | |

| 220 | 80 | 20 | 3 | 9.891 | |

| 240 | 50 | 20 | 2.5 | 7.458 | |

| 240 | 60 | 20 | 2.5 | 7.85 | |

| 240 | 70 | 20 | 2.5 | 8.243 | |

| 240 | 80 | 20 | 2.5 | 8.635 | |

| 240 | 50 | 20 | 3 | 8.949 | |

| 240 | 60 | 20 | 3 | 9.42 | |

| 240 | 70 | 20 | 3 | 9.891 | |

| 240 | 80 | 20 | 3 | 10.362 | |

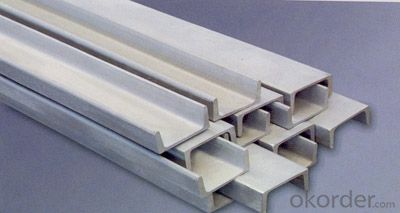

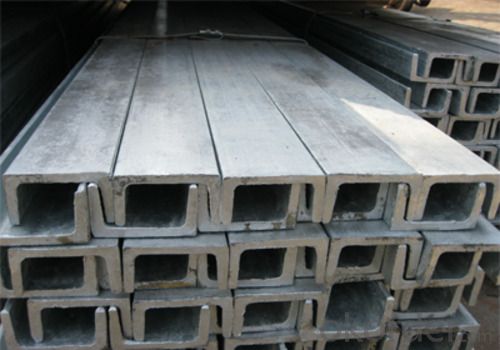

Channel bar

1.Competitive:manufacturer with ISO

2.competitive quality& price

3.Skype: judy.wf

Product Description

Products | Channel bar |

Grade | Q235,SS400B,A36,S235JR.ect |

Type | GB standard(10#-40#,100*48mm--400*102mm) JIS standard(50*25mm--250*90mm) |

Length | 6m, 12m |

Technique | Hot rolled |

Application | Mainly used for building structure, vehicle manufacturing and other industrial structure, channel steel is often used with i beam. |

Payment | 100% irrevocable L/C at sight 30% T/T prepaid and the balance against the copy of B/L |

- Q: What is the typical lifespan of steel channels?

- The lifespan of steel channels can differ depending on various factors such as the quality of the steel used, the installation environment, and the level of maintenance they receive. On average, steel channels typically last between 20 and 50 years. Steel channels are widely utilized in construction and industrial settings because of their strength and durability. They are engineered to withstand heavy loads and offer structural support. However, over time, steel channels can undergo corrosion, wear and tear, and other forms of degradation. To extend the lifespan of steel channels, regular maintenance and protective measures are crucial. This includes conducting routine inspections, cleaning, and applying protective coatings or treatments to prevent corrosion. In addition, proper handling, installation, and load management practices can also contribute to prolonging their lifespan. It is important to recognize that the specific lifespan of steel channels can vary based on the specific conditions they encounter. For example, steel channels installed in coastal areas with high levels of saltwater exposure may experience faster corrosion and a shorter lifespan compared to those installed in inland regions. To determine the expected lifespan of steel channels for a particular application, it is advisable to seek guidance from structural engineers, manufacturers, or industry experts who can provide insights based on the specific project requirements and conditions.

- Q: A solar roof concrete foundation steel embedded parts, steel embedded parts are welded on the welding channel, two channel to head to head up, ask whether the welding part of a steel plate welding lining need? Or what other requirements? What norms do these requirements come from? Thank you

- Butt welding, full welding, through the groove just fine! What about steel plates? No way, single-sided welding, double-sided molding

- Q: What is the wall thickness of national standard 8* channel steel?

- Should refer to the GB 8 channel height 80 leg width 43 waist thickness 5.Channel steel is a strip of steel with a cross section. Section steel with groove shape.Channel steel is divided into ordinary channel steel and light channel steel. Standard Specification for hot-rolled plain channel steel is 5-40#. Specifications for hot rolled flexible channel steel supplied by supply and demand agreement are 6.5-30#. Channel steel is mainly used for building structures, vehicle manufacturing, other industrial structures and fixed plates, cabinets, etc., and channel steel is often used in conjunction with i-beam.According to the channel shape and can be divided into 4 kinds: cold bending equilateral channels, cold-formed non equilateral channel steel, cold rolled edge channels, the cold bending edge channelsAccording to the theory of steel structure, it should be stressed by the channel plate, that is to say, the channel should stand rather than lie prone.

- Q: How do steel channels perform in extreme temperature conditions?

- Steel channels generally perform well in extreme temperature conditions. Steel has a high melting point and excellent thermal conductivity, allowing it to withstand both high and low temperatures without significant structural changes. However, it is important to consider the specific alloy and grade of steel used, as some may have limitations in extreme temperature environments. Additionally, factors such as thermal expansion and contraction should be accounted for in the design and installation process to ensure optimal performance.

- Q: How is the hollow tempered glass mounted on the channel steel?

- Hollow two pieces of glass, there are 4 faces, from outdoor to indoor is defined as 1-4, Low-E glass film surface can only be in the cavity, that is, can only be second or third.Colorless, highly permeable Low-E is placed on third sides (Low-E glass indoors), colored on second sides (Low-E glass outside).In order to prevent the broken glass debris, doubling down side must. Because qualified laminated glass is not damaged when the debris generated, is still able to maintain its integrity.

- Q: How do steel channels contribute to load distribution?

- Load distribution is a crucial function performed by steel channels, which are structural components. These channels are specifically designed to bear heavy loads and transfer them to other supporting elements like beams, columns, or walls. The shape and design of steel channels enable them to efficiently distribute weight and forces applied to them. Steel channels contribute to load distribution primarily by offering a stable and rigid pathway for transferring loads. When a load is applied to a steel channel, it evenly distributes the weight along its length, avoiding the creation of concentrated stress points. This even distribution is crucial in minimizing the risk of structural failure or deformation under heavy loads. Additionally, steel channels often act as secondary support members, helping to distribute loads to primary load-bearing elements. They can be attached to beams, columns, or walls to provide extra support and reinforcement. By connecting different structural elements together, steel channels effectively distribute loads across the entire system, preventing localized stress concentrations and ensuring overall stability and strength. Furthermore, steel channels can be combined with other structural components like steel plates or angles to create composite sections that enhance load distribution capabilities. Engineers can optimize load distribution by utilizing the specific properties of each component and combining different shapes and sizes. In conclusion, steel channels play a critical role in load distribution. They evenly distribute loads, provide additional support to primary load-bearing elements, and create composite sections for enhanced load distribution. Their design and versatility make them essential in ensuring the structural integrity and safety of various types of buildings and structures.

- Q: How do steel channels contribute to sustainable design in buildings?

- Steel channels contribute to sustainable design in buildings in several ways. Firstly, steel is a highly durable and long-lasting material, which means that buildings constructed with steel channels have a longer lifespan, reducing the need for frequent renovations or replacements. This results in less waste generation and a lower environmental impact. Secondly, steel is a recyclable material, which means that steel channels can be recycled and reused after the end of their life cycle. This helps to reduce the demand for new steel production and the associated energy consumption and greenhouse gas emissions. Additionally, steel channels allow for efficient and flexible design options, enabling the construction of lighter and more efficient structures. This leads to reduced material consumption, improved energy efficiency, and lower carbon footprint during the construction and operation phases of the building. Furthermore, steel channels are often used in prefabricated construction methods, which can significantly reduce construction waste, minimize on-site disruption, and improve overall construction efficiency. Overall, the use of steel channels in building design contributes to sustainability by promoting durability, recyclability, energy efficiency, and reduced waste generation, making it a preferred choice for sustainable building practices.

- Q: How are steel channels manufactured?

- Steel channels are manufactured through a process called hot-rolling, which involves heating a steel billet and passing it through a series of rollers to shape it into a channel. This process ensures the channels have consistent dimensions and strength.

- Q: What are the design considerations when using steel channels?

- There are several important factors to consider when using steel channels in design. To begin with, it is crucial to calculate the load-bearing capacity of the steel channel accurately. This involves determining the maximum load that the channel will endure and ensuring that the chosen channel size and shape can adequately support this load without any deformation or failure. Factors such as material strength, cross-sectional shape, and channel size must be taken into account. Another consideration of utmost importance is the structural stability of the steel channel. It is vital to evaluate whether the channel will face any external forces or vibrations and design it in a way that it can resist these forces without buckling or collapsing. This may involve incorporating reinforcements or bracing elements to enhance the channel's stability. Additionally, the environmental conditions in which the steel channel will be used should be considered. Factors like temperature fluctuations, exposure to corrosive substances, or the potential for moisture accumulation can affect the performance and durability of the steel channel. Appropriate measures, such as protective coatings or material selection, should be implemented to ensure the long-term functionality and integrity of the channel. Moreover, when designing with steel channels, it is essential to consider the ease of fabrication, installation, and maintenance. The selected channel size and shape should be compatible with standard manufacturing processes and construction techniques, allowing for efficient installation in the desired application. Additionally, potential future maintenance requirements, such as accessibility for repairs or modifications, should be taken into account. Lastly, the aesthetic and architectural requirements of the project should not be overlooked. Steel channels can serve as architectural elements, and their design should align with the overall aesthetic vision of the project. This may involve selecting a specific finish or surface treatment that complements the desired appearance. In summary, the design considerations for steel channels encompass load-bearing capacity, structural stability, environmental conditions, fabrication and installation feasibility, maintenance requirements, and aesthetic compatibility. By carefully addressing these factors, designers can ensure the successful implementation of steel channels in their projects.

- Q: What are the different types of connections for steel channels in modular office systems?

- Steel channels in modular office systems can be connected using various methods to ensure stability and structural integrity. One widely used method is the bolted connection, which involves securing the steel channels together using bolts. These bolts are inserted through pre-drilled holes in the channels and then tightened with nuts. Bolted connections are relatively simple to install and offer a strong and dependable connection. Another option is the welded connection, which involves melting the metal at the connection points and allowing it to solidify, thereby joining the steel channels together. Welded connections are highly durable and provide exceptional strength. However, they require skilled labor and specialized equipment to be properly executed. A third alternative is the riveted connection, where rivets are used to secure the steel channels together. The rivets are inserted through pre-drilled holes in the channels and then deformed to hold them in place. Riveted connections are known for their ability to carry heavy loads and resist vibrations. However, they may be more time-consuming to install compared to bolted connections. Additionally, adhesive connections can also be used. This method involves using high-strength adhesives to bond the steel channels together. Adhesive connections are often used in combination with other connection methods to provide additional stability. They are particularly useful when drilling or welding is not feasible or desirable. To summarize, the available connection options for steel channels in modular office systems include bolted connections, welded connections, riveted connections, and adhesive connections. Each method has its own advantages and considerations, and the choice will depend on factors such as load requirements, installation limitations, and budget constraints.

Send your message to us

Channel Steel Galvanized for House, Wall, Ceiling

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords