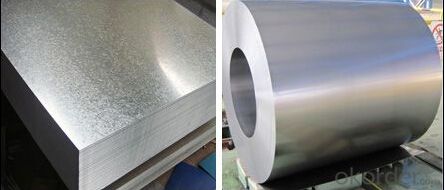

Galvanized Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Specification:

Thickness: 0.2-3.0mm

Width: 600-1500mm

Coating Mass: Z08,Z12,Z18,Z20,Z22,Z25,Z27,Z35

Z80,Z120,Z180,Z200,Z220,Z250,Z275

Tolerance for thickness,width,flatness and so on conform to the requirements of JIS G3302 or ASTM A653M/924M

Coil ID can be either 508mm or 610mm, maximum coil OD is 2000mm

The speicfication of ASTM Such as A653m,A924 M and so on have been updated to the latest revisions

Application:

BUILDING & CONSTRUCTION

Floor decks, ceilings, verandas, rolling doors, warehouse, partitions, sheds, gutters, wall, underground piping, sashes, beams, fences, scaffolding, indoor decorations, ducts, ventilating pipes, steel frames and cable trays.

ELECTRICAL APPLIANCES

Freezers, video recorder cases, motor cases, lighting fittings, water heaters, washing machines, refrigerators, stoves, air conditioners, dehumidifiers, fluorescent light housings, electrical heaters, toasters, microwave oven enclosures and switch boxes.

TRANSPORTATION

Containers, under body panels, bus & truck body panels, fuel tanks, noise screens, highway signs, air cleaners, conveyor systems and guard rails.

AGRICULTURAL EQUIPMENT

Barns, drying machines, animal houses, hoppers, irrigation systems, greenhouses, water tanks, sheds, silos, agricultural implements and feeders.

FURNITURE & OTHERS

Vending machines, drums, cans, pails, sauna inner parts, chimney pipes, entertainment machines, solar collectors, office equipment, steel furniture, tool boxes, garages and waste bins.

COMPUTER'S APPLIANCES

Computer shells and communication instruments。

Surface Treatment:

Chromating treatment or anti-finger print

Surface Finished:

REGULAR SPANGLE:

Regular spangle is also called normal spangle which is naturally formed without any additional treatment during galvanizing.

MINI SPANGLE:

The spangle is restrained and formed as mini spangle by reducing the lead content in the zinc liquid or by blowing the zinc powder from the equipment installed on the zinc pot.

EXTRA SMOOTH:

The mini spangle is further skin-passed to produce the extra smooth surface.

- Q: I am in the US and looking for a price on wide flange steel. I need a price of one W10x30 and 20 feet long.

- The price of steel is increasing daily, so an exact answer is rough. A W10x30 is a fairly common shape and shouldn't be too hard to find. For a very rough ballpark number, say $700/ton (installed price), the piece you require should be in the range of about $250.00 or less as I assume you'll be doing the installing. Please don't take this as the gospel, however. Price varies on location, stock, and availability. Open the phone book and contact your local steel supplier. Because the piece you require is fairly short, you might get lucky and find someone who has a waste piece that length that they will give you a good deal on. --------------------------------------... I just checked the AISC web site to verify the number I quoted above and they posted an article stating that the average mill price had just increased to over $1000/ton in May. The best advice I can provide at this point is to buy the W10 now and don't wait any longer.

- Q: I heard about a new bike the specialized allez steel. Has anyone heard anything about it. it will have all brand new components like shimano 2300 parts and everything. it looks nice.

- Steel? I doubt it's made out of steel, more labor and a heavier frame. Most likely aluminum. Shimano 2300 you say? The Shimano 2300 is the lowest of the low of Shimano road components. Most likely not too reliable and heavy. www.cyclestore .uk/productDetai... I think this is what you might be looking for.

- Q: Are you people aware of commercial steel warehouses, If yes then can you please explain their advantages and benefits?

- Steel okorder /

- Q: Is it faster to smith steel or mithril in Rinescape assuming I'm going to mine everything myself?Mining level: 76Smithing level: 55

- steel, it will take you way to long to mine mithril ore, and all the coal. also if you make steel plate bodies they actually sell becuase people use it to make steel titian pouches

- Q: Stains tends to leave on the stainless steel microwave oven and its very hard to clean off the stain (brownish stain) please suggest the best way to remove it.

- They make a stainless steel polish that will do the trick.

- Q: How are steel coils inspected for surface defects?

- Steel coils are inspected for surface defects using various techniques such as visual inspection, automated systems, and magnetic particle inspection. Visual inspection involves trained personnel examining the coils for any visible defects or irregularities. Automated systems utilize cameras and sensors to detect defects and anomalies on the coil surfaces. Magnetic particle inspection, on the other hand, involves magnetizing the coil and applying magnetic particles to reveal any surface defects through the formation of visible indications. These methods ensure that steel coils meet quality standards before further processing or shipment.

- Q: How are steel coils used in the production of construction components?

- Steel coils are used in the production of construction components in various ways. One common use is for the manufacture of steel beams and columns, which are essential structural elements in buildings and other large structures. The steel coils are processed and shaped into the desired dimensions, then cut and welded to form the beams and columns. Steel coils are also used in the production of roofing and wall cladding materials for construction. These coils are often coated with protective layers to enhance durability and resistance to corrosion. The coils are then shaped and formed into roofing sheets, wall panels, or siding materials that provide both aesthetic appeal and functional protection to the building. Another important application of steel coils in construction is for the production of reinforcing bars, commonly known as rebar. Rebar is used to provide strength and stability to concrete structures, such as foundations, slabs, and walls. The steel coils are processed and cut into specific lengths, then shaped and twisted to form the required reinforcement bars, which are then embedded within the concrete during construction. Furthermore, steel coils can be used in the production of various other construction components, such as pipes, tubes, and profiles. These components are used for plumbing, heating, ventilation, and other structural applications. The steel coils undergo different manufacturing processes, including rolling, welding, and shaping, to achieve the desired dimensions and properties of these components. In summary, steel coils play a crucial role in the production of construction components. They are used to manufacture steel beams, columns, roofing and wall cladding materials, reinforcing bars, pipes, tubes, and profiles. These components are vital for the construction industry, as they provide strength, durability, and functionality to buildings and other structures.

- Q: Can steel coils be coated with aluminum?

- Yes, steel coils can be coated with aluminum through a process called coil coating.

- Q: How are steel coils used in the manufacturing of electrical equipment?

- Steel coils are used in the manufacturing of electrical equipment as they serve as the core material for transformers and inductors. These coils are wound with copper wire to create electromagnetic fields necessary for the functioning of various electrical devices.

- Q: How do steel coils contribute to the water and wastewater industry?

- Steel coils contribute to the water and wastewater industry by being used in the construction of pipes, tanks, and other infrastructure. These coils provide strength, durability, and corrosion resistance, ensuring the integrity and longevity of water and wastewater systems. Additionally, steel coils are often utilized in the manufacturing of water treatment equipment and machinery, helping to improve the efficiency and effectiveness of the water and wastewater treatment processes.

Send your message to us

Galvanized Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords