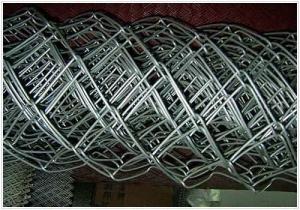

GALVANIZED WIRE STEEL MESH

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

| ||

My company is mainly manufacturing fence:Guard fence with double end wire、Frame guard fence、Triangle guard

fence、Double circle guard fence、Jail guard fence security fence.

fence、Double circle guard fence、Jail guard fence security fence.

Mainly used for highway, railway, airport, station, port, service and transportation Factory, workshop, residential space,

landscape, municipal flower, Security architecture, such as decorative protection effect. According to customer needs has a variety

of specifications and flexible fixed way.

landscape, municipal flower, Security architecture, such as decorative protection effect. According to customer needs has a variety

of specifications and flexible fixed way.

- Q: What are the different fastening methods for steel wire mesh?

- There are several different fastening methods that can be used to secure steel wire mesh in various applications. Some of the most common methods include: 1. Welding: Welding is a popular fastening method for steel wire mesh, especially in industrial settings. It involves melting the wire mesh and the adjoining material together to create a strong bond. This method is particularly effective for permanent installations where strength and durability are essential. 2. Zip ties: Zip ties, also known as cable ties or wire ties, are a quick and easy way to fasten steel wire mesh. These plastic ties are threaded through the mesh and then secured by pulling them tight. Zip ties are widely used in temporary installations or situations where frequent adjustments may be required. 3. Clips and clamps: Clips and clamps are often used to secure steel wire mesh panels together. These metal or plastic accessories are designed to grip the edges of the mesh and hold them in place. Clips and clamps provide a secure and reliable fastening method while allowing for easy disassembly and reassembly if needed. 4. Screws and nails: Steel wire mesh can also be fastened using screws or nails. This method is commonly used in construction and woodworking projects where the mesh needs to be attached to a solid substrate, such as wood or metal. Screws and nails offer a sturdy and permanent fastening solution. 5. Cable lacing: Cable lacing, also known as lacing cord or lacing wire, is a traditional method of fastening steel wire mesh. It involves using a thin wire or cord to lace through the mesh and tie it securely. Cable lacing is often used in applications where flexibility and adjustability are necessary. 6. Adhesives: In some cases, adhesives can be used to fasten steel wire mesh to surfaces. Specialized adhesives designed for bonding metal can be applied to the mesh and the substrate, creating a strong and permanent bond. However, this method may not be suitable for all applications and should be carefully considered based on the specific requirements and conditions. Overall, the choice of fastening method for steel wire mesh depends on factors such as the application, installation requirements, and desired level of permanence. It is important to consider the strength, durability, and ease of installation when selecting the appropriate method for a particular project.

- Q: How does steel wire mesh perform in terms of flexibility?

- Known for its exceptional flexibility, steel wire mesh can easily be bent, twisted, or molded into various shapes and sizes without compromising its structural integrity, thanks to its construction using interlocking wires. This outstanding flexibility renders steel wire mesh highly versatile and appropriate for a wide range of applications. It finds use as reinforcement in concrete structures, fencing, screens, filters, and even as a material for artistic or decorative purposes. Moreover, the flexibility of steel wire mesh enables effortless installation and customization to meet specific project requirements. All in all, steel wire mesh is widely favored in many industries due to its excellent flexibility.

- Q: Screen printing and screen printing plate on the photosensitive material What are the requirements

- posters, business cards, binding cover, product signs and printing and dyeing textile and other silk screen pollution process first plate production The use of ink in the developer is the production of ink bucket cleaning is to produce cleaning waste or waste wipe

- Q: Is steel wire mesh resistant to vandalism?

- Due to its sturdy and long-lasting nature, steel wire mesh can be considered resistant to vandalism. It is widely utilized in various applications where security and protection are crucial, such as fences, enclosures, and barriers. The strong construction of steel wire mesh makes it challenging for vandals to easily break or damage it. Moreover, the mesh design with small openings prevents unauthorized access or tampering with the protected area. However, it is important to acknowledge that no material is completely impervious to vandalism. Determined individuals equipped with the appropriate tools and ample time may still be able to inflict some damage on steel wire mesh. Therefore, while it offers a high level of resistance, it is always advisable to implement additional security measures when vandalism is a concern.

- Q: Can steel wire mesh be used for safety nets?

- Yes, steel wire mesh can be used for safety nets. Steel wire mesh is a versatile material that can provide a strong and durable structure for safety nets. It is commonly used in various industries, such as construction and sports, to create safety barriers and nets. Steel wire mesh has several advantages that make it suitable for safety nets. Firstly, it is highly resistant to impact and can withstand heavy loads, making it an ideal material for ensuring the safety of individuals in hazardous areas or high-risk activities. Additionally, steel wire mesh is corrosion-resistant, which means it can withstand exposure to different weather conditions and harsh environments. Furthermore, steel wire mesh offers excellent visibility due to its open design, allowing for better monitoring and supervision of activities while maintaining safety. It also provides good ventilation, reducing the risk of heat stress or suffocation in confined spaces. However, it is important to ensure that the steel wire mesh used for safety nets meets the specific requirements and regulations for safety standards. The mesh size, wire diameter, and overall strength should be considered to ensure the net can effectively catch and hold individuals or objects in case of a fall or accident. Overall, steel wire mesh is a suitable material for safety nets due to its strength, durability, visibility, and ventilation properties. It can be used in a wide range of applications where safety is paramount, providing reliable protection and peace of mind.

- Q: Is steel wire mesh suitable for use in wastewater treatment plants?

- Wastewater treatment plants can utilize steel wire mesh as it is a suitable option. This material is known for its durability and versatility, allowing it to withstand tough conditions and effectively carry out filtration and separation tasks. In wastewater treatment plants, steel wire mesh finds applications in screening, filtering, and dewatering processes. The strength and stability of steel wire mesh are exceptional, enabling it to endure high pressures and flow rates that are commonly encountered in wastewater treatment procedures. It is capable of retaining solid particles, debris, and other impurities while still allowing water to flow through. Consequently, this aids in the elimination of contaminants and enhances the overall quality of the treated water. Moreover, steel wire mesh possesses resistance against corrosion, chemicals, and extreme temperatures, making it highly suitable for the aggressive and demanding environment of wastewater treatment plants. Additionally, it is easy to clean and maintain, ensuring a longer lifespan and cost-effectiveness. All in all, when considering its durability, versatility, and ability to withstand harsh conditions, steel wire mesh proves to be a reliable and efficient choice for wastewater treatment plants.

- Q: Can steel wire mesh be used for creating safety nets?

- Yes, steel wire mesh can be used for creating safety nets. Steel wire mesh is a strong and durable material that can effectively prevent falls and provide a protective barrier. It is commonly used in construction sites, sports facilities, and other areas where safety is crucial.

- Q: Is steel wire mesh suitable for use in window screens?

- Indeed, steel wire mesh proves to be a fitting option for window screens. Renowned for its enduring nature and robustness, steel wire mesh emerges as an exceptional preference in this regard. Its capacity to endure severe weather conditions, ward off corrosion, and offer heightened security sets it apart. Moreover, steel wire mesh boasts commendable transparency, facilitating optimal airflow while effectively barring insects and other nuisances. Given its strength and durability, steel wire mesh emerges as a dependable choice for window screens, diligently safeguarding the well-being and tranquility of any abode or edifice.

- Q: How is steel wire mesh used in reinforcement of hospitals?

- Steel wire mesh is commonly used in the reinforcement of hospitals due to its high tensile strength and durability. It is primarily utilized in the construction of reinforced concrete structures such as columns, beams, and slabs. In hospitals, steel wire mesh is often embedded within the concrete walls and floors to enhance their structural integrity and provide resistance against external forces. This reinforcement ensures that the hospital buildings can withstand the weight of heavy equipment, machinery, and the constant movement of people. Furthermore, steel wire mesh acts as a reinforcement to prevent cracks and fractures in the concrete, which can compromise the safety and functionality of the hospital. It helps distribute the load evenly across the concrete surface, reducing the risk of structural failure. Steel wire mesh is also used in the construction of masonry walls, providing additional support and stability. It prevents the walls from bulging or collapsing under the pressure of natural disasters such as earthquakes or high winds. Additionally, steel wire mesh is commonly utilized in the reinforcement of hospital ceilings. By installing steel wire mesh between the ceiling joists, it helps reinforce the ceiling structure and prevent sagging or collapsing. This is crucial in critical areas such as operating rooms, where heavy medical equipment is suspended from the ceiling. In summary, steel wire mesh plays a pivotal role in the reinforcement of hospitals. Its high strength and durability make it ideal for enhancing the structural integrity of various components, ensuring the safety and functionality of these critical healthcare facilities.

Send your message to us

GALVANIZED WIRE STEEL MESH

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords