Galvanized Steel Strips with Width 400mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Hot-Dip Galvanized Steel Strips Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

2. Main Features of the Hot-Dip Galvanized Steel Strips:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

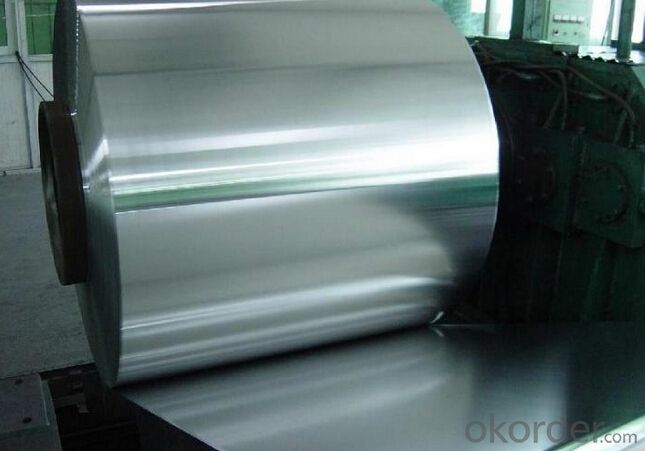

3. Hot-Dip Galvanized Steel Strips Images

4. Hot-Dip Galvanized Steel Strips Specification

1) Capacity: about 15,000 tons per month for sheet product.

2) Standard: JIS G3302 1998, ASTM A653M/A924M 2004, all according to the customer's request

3) Thickness: 0.13mm-0.5mm

4) Width: 400mm-1000mm

5) Length: We can adjust the length according to your request

6) Zinc Coating Weight: 60g/m2-275g/m2

7) Raw Materials: Galvanized steel sheet and Pre-painted galvanized steel sheet

8) Spangle: Regular spangle, minimized spangle and zero spangle

9) Hardness: Full hard, normal

5.FAQ of Hot-Dip Galvanized Steel Strips

We have organized several common questions for our clients,may help you sincerely:

1. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2. How long can we receive the product after purchase?

Production period is 30 days. And we’d prefer you can give us more time to book vessel.

3. What’s the usage of galvanized steel strips?

Auto manufacture, Oil drum, Transformer's tank panel, Furniture etc.

- Q: How do steel coils contribute to seismic resistance in structures?

- Steel coils contribute to seismic resistance in structures by providing strength and flexibility. The coiled shape allows the steel to absorb and dissipate the energy generated during seismic events, thereby reducing the impact on the structure. This increased flexibility helps prevent the structure from collapsing under the stress of seismic forces, making it more resistant to earthquakes.

- Q: What products can we make with steel (eg Steel strip, rod, bar, rail, tube) How are these made? What can we make from these steel products?Can you please make the answers as detailed as possible you can because i really want to know this really well. Thank you.

- Your okorder (they make steel deck and steel joists) There are thousands of other items routinely produced from steel, including rebar, and all the metal in cars, airplanes, and about a million other things.

- Q: What is the standard width of steel coils?

- Depending on the industry and application, the width of steel coils can differ. Generally, steel coils have a standard width range of 36 to 72 inches. The actual width is influenced by various factors including the type of steel, intended use, and the machinery involved in processing and handling the coils. To ensure the appropriate width for a specific steel coil application, it is crucial to refer to industry standards and specifications.

- Q: I have been searching on pots and pans, how can I find out if it's really stainless steel, someone told me if a magnet sticks to it it's real stainless steel is this true?

- Some types of stainless are magnetic and some are not. being magnetic isn't a reliable way to tell the difference. In fact, only the cheapest pots would be made out of grades of stainless that are magnetic. Stainless pots/pans are generally made of non-magnetic types, but then again, aluminum isn't magnetic either. Aluminum and stainless are superficially very similar.

- Q: How are steel coils processed at the steel service centers?

- Steel coils are processed at steel service centers through a series of steps to transform them into finished products that meet the specific requirements of customers. The process typically begins with the arrival of the steel coils at the service center. These coils are typically large and heavy, and may have been produced by a steel mill or imported from overseas. Once the steel coils are received, they are typically inspected for quality and any defects. This ensures that only high-quality coils are used in the production process. The coils are then stored in a warehouse until they are ready to be processed. Next, the steel coils are uncoiled. This involves unwinding the coil to create a flat sheet of steel. This can be done manually or using automated machines depending on the size and thickness of the coils. The uncoiled steel is then leveled to remove any residual stress and ensure a flat and consistent surface. After leveling, the steel sheets may undergo various processes depending on the desired end product. These processes can include cutting, shearing, slitting, and forming. Cutting and shearing involve cutting the steel sheets into specific sizes or shapes. Slitting involves cutting the steel into narrow strips, while forming involves bending or shaping the steel into the desired form. Once the desired processing operations are complete, the steel sheets are often treated with surface finishes to enhance their appearance or protect them from corrosion. These finishes can include painting, coating, or galvanizing. Finally, the processed steel sheets are inspected for quality again to ensure they meet the required specifications. They are then packaged and ready for shipment to customers, who may use them in various industries such as construction, automotive, or manufacturing. Overall, the processing of steel coils at steel service centers involves a combination of inspection, uncoiling, leveling, cutting/shearing/slitting/forming, surface finishing, quality control, and packaging. This process allows for the transformation of steel coils into finished products that are tailored to meet the specific needs and requirements of customers.

- Q: How are steel coils inspected for hardness?

- Steel coils are inspected for hardness using a non-destructive testing method called Rockwell hardness testing. This involves pressing a diamond or ball indenter into the surface of the coil and measuring the depth of the indentation. The hardness value is then determined based on the depth of the indentation, providing an accurate assessment of the coil's hardness.

- Q: Can steel coils be used in corrosive environments?

- Steel coils have the potential to be utilized in corrosive environments, but their effectiveness relies on the specific steel used and the degree of corrosiveness in the environment. For instance, stainless steel coils furnish exceptional resistance against corrosion and can function effectively in a diverse range of corrosive surroundings, even those with elevated levels of moisture, chemicals, or salt. Conversely, alternative types of steel coils might necessitate supplementary safeguards, such as coatings or galvanization, to augment their resistance to corrosion. It is imperative to carefully evaluate the particular corrosive elements present in the environment and select the appropriate steel type and protective measures to guarantee the long-lasting and durable performance of the steel coils.

- Q: How do steel coils contribute to the manufacturing of oil and gas equipment?

- Steel coils play a vital role in the production of oil and gas equipment, as they are an essential component. Typically, these coils are made from high-quality steel that is durable, strong, and resistant to corrosion. This makes them ideal for enduring the harsh environments and conditions encountered in the oil and gas industry. One of the primary uses of steel coils in oil and gas equipment manufacturing is in the creation of pressure vessels. These vessels are crucial for storing and transporting fluids and gases under high pressure. Steel coils are used to form the cylindrical shells of these vessels, providing the necessary strength and structural integrity to withstand the internal pressure. Steel coils are also utilized in the construction of oil and gas pipelines. These pipelines are responsible for transporting large quantities of oil and gas over long distances. Steel coils are used to manufacture the pipes that compose these pipelines, ensuring they have the necessary strength, durability, and resistance to corrosion. The coils are rolled and welded to create seamless or welded pipes, which are then coated or lined to prevent corrosion and increase their lifespan. Additionally, steel coils are instrumental in the production of drilling equipment used for extracting oil and gas. This equipment includes drill bits, casings, and wellheads, which are essential for drilling and completing wells. The coils are used to fabricate these components, ensuring they can withstand the demanding conditions encountered during drilling operations. Aside from their structural applications, steel coils are also used in the manufacturing of ancillary equipment like tanks, storage containers, and heat exchangers. These components play a crucial role in the processing, storage, and distribution of oil and gas. Steel coils provide the necessary strength and durability to handle the harsh conditions and corrosive substances encountered in these processes. In conclusion, steel coils are indispensable in the manufacturing of oil and gas equipment. Their strength, durability, and resistance to corrosion make them a preferred choice in the industry. By contributing to the fabrication of pressure vessels, pipelines, drilling equipment, and ancillary components, steel coils ensure the safe and efficient extraction, processing, and transportation of oil and gas.

- Q: How are steel coils used in the manufacturing of metal structures?

- Steel coils are used in the manufacturing of metal structures as they are shaped and formed into various components such as beams, columns, and plates. These coils are unrolled and processed through machines that cut, shape, and weld them together to create the desired structure. The strength and durability of steel make it an ideal material for constructing buildings, bridges, and other metal structures.

- Q: I have been wanting a new pair of hiking boots, but haven't had the money. I just got a job that requires me to have steel toed boots. The job is only for a few weeks, but I may be required to wear them on other jobs in the future. Regardless of which style I get, I will most likely be buying Red Wing boots. On their website, I see they have steel toed hiking boots. What is the purpose of a steel toed hiking boot? Why would a hiker need to have steel toed boots? Wouldn't that just be more weight? I see that some of their hiking boots have aluminum toes, claiming to be 33% lighter than steel with the same protection. Would these boots be good potential hiking boots as well as suitable for construction or should I just focus on work boots and buy myself some hiking boots at a later date?

- Hi! You can hike in steel toed boots, but I wouldn't. They aren't designed for hiking, no matter what the manufacturers says. They're built to protect your feet from hazards on a job site. I bought my first pair of decent hiking boots for $10/month on layaway at an outfitters. It took forever, of course, but I didn't have the money to buy them right out. Until then, I hiked in a pair of tennis shoes. Sneakers are just fine as hiking gear, though remember that you will have no ankle support, so you need to be more careful on rocky trails. Use a pair you don't mind getting dirty and make sure they have decent ankle support. Also, this is a great time of year to buy boots if you can scrounge the money together. Most outfitters are swapping over to their spring lines and have shoe/boot sales going on. You don't have to use an outfitter, either. Lots of regular shoe or department stores sell boots that will work just fine until you can afford some nice top-line boots.

Send your message to us

Galvanized Steel Strips with Width 400mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords