Galvanized Steel Sheet in Ciols with Prime Quality Best Seller

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Galvanized Steel Coil Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. 2.Main Features of the Galvanized Steel Coil:

• Base material for countless outdoor and industrial applications

• High corrosion resistance

• High strength

3.Galvanized Steel Coil Images

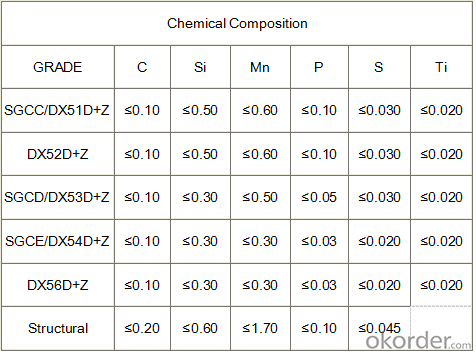

4.Galvanized Steel Coil Specification

Operate Standard: ASTM A653M-04/JIS G3302/DIN EN10143/GBT 2518-2008

Grade : SGCD,SGCH, Q195,DX51D

Zinc coating :40-180g( as required)

Width:914-1250mm(914mm, 1215mm,1250mm,1000mm the most common)

5.FAQ of Galvanized Steel Coil

We have organized several common questions for our clients,may help you sincerely:

1.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

- Q: How are steel coils used in the manufacturing of shipping containers?

- Steel coils are used in the manufacturing of shipping containers as they are rolled into sheets, which are then cut and welded to create the walls, roof, and floor of the container. The high strength and durability of steel coils ensure that the shipping containers can withstand the rigors of transportation, protecting the goods inside.

- Q: What are the common quality control measures for steel coils?

- To ensure the performance and reliability of steel coils, several common quality control measures are implemented. These measures play a crucial role in upholding the overall quality of the coils and ensuring their compliance with the necessary standards and specifications. To begin with, dimensional checks are conducted to verify that the steel coils possess the correct thickness, width, and length. Deviations from the specified dimensions can significantly impact the coils' functionality and usability, making this check of utmost importance. Following that, visual inspections are carried out to identify any surface defects or imperfections such as scratches, dents, or corrosion. These inspections aid in identifying potential issues that could compromise the structural integrity of the coils or affect their aesthetic appearance. Moreover, mechanical property tests are performed to assess the strength, hardness, and other mechanical characteristics of the steel coils. These tests provide valuable insights into the coils' performance and durability under different conditions and loads. An essential quality control measure for steel coils is the analysis of their chemical composition. This involves scrutinizing the steel's composition, including the presence of any impurities or elements that may impact its properties. It ensures that the coils are made from the correct grade of steel and meet the required chemical specifications. Coating inspections also play a vital role in quality control. When steel coils are coated with protective layers, it is imperative to examine the adhesion, thickness, and uniformity of these coatings. This examination ensures that the coils have sufficient protection against corrosion and other environmental factors. Lastly, various non-destructive testing methods, such as ultrasonic testing, magnetic particle inspection, or eddy current testing, are employed to detect any internal defects or abnormalities in the steel coils. These tests enable the identification of issues like cracks, inclusions, or discontinuities that may not be visible through visual inspection alone. In conclusion, the quality control measures for steel coils consist of dimensional checks, visual inspections, mechanical property tests, chemical composition analysis, coating inspections, and non-destructive testing. These measures are vital in maintaining the quality and reliability of steel coils, guaranteeing their compliance with the required standards, and meeting customer expectations.

- Q: Can steel coils be coated with anti-slip materials?

- Yes, steel coils can be coated with anti-slip materials.

- Q: How are steel coils used in the production of electrical devices?

- Steel coils are commonly used in the production of electrical devices as they serve as crucial components in transformers, motors, and generators. These coils are typically made from high-quality steel and are wound with copper wire to create an electromagnetic field. This field helps in the conversion, transmission, and regulation of electrical energy, making steel coils indispensable for the efficient operation of electrical devices.

- Q: would you consider steel a flexible substance...i am debating this with my coworkers.Thanks,

- Steel is a flexible material. It can be deformed and return to it's original shape up while the stress applied is still in the elastic range. How flexible depends on size, shape, and alloy. Some alloys are more flexible than others and a lot of this is controlled by carbon content.

- Q: What are common uses for steel coils?

- Steel coils are commonly used in various industries such as automotive, construction, and manufacturing for applications like sheet metal fabrication, structural components, pipes, and electrical appliances.

- Q: a steel abr sells for about 879 now...a mith just over 1kany suggestions on which-keyword WHICH steel item to make-which is the best-exp wise, and steel bar conservative wise.

- Mining okorder /

- Q: How do steel coils contribute to the sustainability of construction projects?

- There are several ways in which steel coils contribute to the sustainability of construction projects. First and foremost, steel is a highly durable and long-lasting material. Manufactured to withstand extreme weather conditions, corrosion, and other external factors, steel coils are ideal for construction projects that require strength and longevity. This durability reduces the need for frequent repairs and replacements, resulting in minimized waste and resource consumption over time. Moreover, steel coils are recyclable. Once their lifespan in a construction project comes to an end, steel coils can be easily and efficiently recycled. This recycling process requires less energy compared to the production of new steel, leading to reduced carbon emissions and environmental impact. Furthermore, the recycled steel can be utilized in various industries, including construction, thereby promoting sustainability and resource conservation. Additionally, steel coils contribute to the sustainability of construction projects by offering design flexibility. Being a versatile material, steel can be easily shaped, cut, and molded into different forms and sizes. This allows for efficient construction practices, reducing material wastage and optimizing resource utilization. Furthermore, the lightweight nature of steel coils enables convenient transportation and installation, further decreasing fuel consumption and associated greenhouse gas emissions. Lastly, steel coils contribute to the sustainability of construction projects through their energy efficiency. Being an excellent conductor of heat and electricity, steel is ideal for energy-efficient buildings. By incorporating steel coils into the construction of walls, roofs, and other components, buildings can be effectively insulated, resulting in reduced energy consumption for heating and cooling. Consequently, occupants benefit from lower energy bills, while the overall carbon footprint of the construction project is reduced. In conclusion, steel coils contribute to the sustainability of construction projects through their durability, recyclability, design flexibility, and energy efficiency. By utilizing steel coils, construction projects can minimize waste, conserve resources, reduce environmental impact, and optimize energy consumption, thereby promoting a more sustainable and eco-friendly approach to construction.

- Q: How do steel coils contribute to the manufacturing of HVAC systems?

- The manufacturing of HVAC systems heavily relies on steel coils, which have a critical role. These coils typically consist of high-quality steel, known for its exceptional strength, durability, and resistance to heat. Heat exchangers are one of the primary applications of steel coils in HVAC systems. These exchangers play a vital role in transferring heat between different mediums, usually air and a refrigerant. In HVAC systems, steel coils are employed in both the evaporator and condenser coils. The evaporator coil absorbs heat from the indoor air, while the condenser coil releases heat to the external environment. These coils are designed with numerous coiled tubes connected by fins. The use of steel in their construction ensures their ability to withstand high pressure and resist corrosion, guaranteeing the long-term reliability and efficiency of the HVAC system. Steel coils also contribute to the overall structural integrity of HVAC systems. They are commonly utilized in the fabrication of ductwork, responsible for distributing conditioned air throughout a building. The strength and rigidity of steel coils enable the ductwork to maintain its shape and structural integrity under various conditions, including high air pressure and temperature fluctuations. Additionally, steel coils are frequently involved in the fabrication of HVAC system cabinets and enclosures. These cabinets house several system components, including compressors, fans, and control panels. The robustness of steel coils ensures that the cabinets can withstand external forces, protect the internal components, and provide a secure housing for the entire HVAC system. To summarize, steel coils are crucial components in the manufacturing of HVAC systems. Their strength, durability, and heat resistance make them ideal for applications such as heat exchangers, ductwork, cabinets, and enclosures. By incorporating steel coils, HVAC manufacturers can produce systems that efficiently regulate temperature, enhance indoor air quality, and provide comfort in various residential, commercial, and industrial settings.

- Q: How are steel coils used in the manufacturing of suspension systems?

- Steel coils are commonly used in the manufacturing of suspension systems as they provide the necessary support and flexibility to absorb shocks and vibrations. These coils are typically shaped into springs and placed in the suspension system of vehicles, helping to maintain stability, improve handling, and ensure a smooth ride by absorbing the impact from uneven surfaces on the road.

Send your message to us

Galvanized Steel Sheet in Ciols with Prime Quality Best Seller

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords