Galvanized Steel Sheet in Ciols with Prime Quality and Best Seller

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

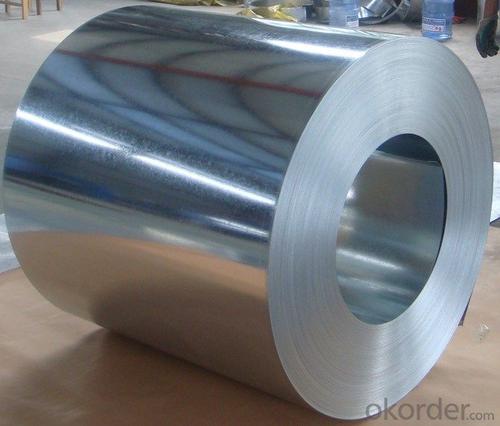

1.Structure of Galvanized Steel Coil Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc.

2.Main Features of the Galvanized Steel Coil:

• Good formability • Rust- proof ability • Good visual effect • Base material for countless outdoor and industrial applications

• High corrosion resistance

• High strength

3.Galvanized Steel Coil Images

4.Galvanized Steel Coil Specification

Width:914-1250mm(914mm, 1215mm,1250mm,1000mm the most common) Grade : SGCD,SGCH, Q195,DX51D

Zinc coating :40-180g( as required)

Coil id:508mm/610mm

Coil weight: 4-10 MT(as required)

Surface: regular/mini/zero spangle, chromated, skin pass, dry etc.

5.FAQ of Galvanized Steel Coil

We have organized several common questions for our clients,may help you sincerely:

1.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: What are the different types of steel processing techniques for coils?

- There are several types of steel processing techniques for coils, including hot rolling, cold rolling, annealing, pickling, and galvanizing.

- Q: Can steel coils be coated with anti-slip materials?

- Yes, steel coils can be coated with anti-slip materials.

- Q: What is the average price of a steel coil?

- The average price of a steel coil can vary depending on factors such as the type of steel, size, and market conditions. It is best to consult with suppliers or industry reports for the most up-to-date and specific information on current average prices.

- Q: i mean cor ten steel( rusted)

- If the steel is true Cor Ten steel, it does not require waxing. Cor Ten is a steel designed to rust slowly over time ... then the rust acts as a natural barrier to prevent further rust. Check out the United States Steel building in downtown Pittsburgh, PA ... its nickname is The Rusty Nail.

- Q: i have a computer chair where the metal part that attachs the top part to the bottom with wheels has cracked around half of the assembly. my dad said it might be able to be repaired with jb weld. can jb weld fix it? how strong is jb weld? is it as strong as steel?

- There is going to be too much stress at that mounting point for jb to work for long, unless you plan on never leaning more than 5 degrees from prostrate. Buy a new or used one. They are cheap if your not too picky. If you do plan on using jb, i highly recommend drilling multiple 1/8 or so holes on both sides of the crack, and smash some jb into those holes as you patch it. That will allow the jb to hold on much better.

- Q: Can steel coils be coated with weather-resistant materials?

- Yes, steel coils can be coated with weather-resistant materials. These coatings provide protection against corrosion, moisture, UV rays, and other environmental factors, helping to enhance the durability and longevity of the steel coils, especially when used in outdoor or exposed applications.

- Q: What are the different methods of cut-to-length shearing for steel coils?

- Steel coils can be cut-to-length using various methods, each with unique advantages and applications. Some commonly used methods include: 1. Rotary Shearing: This technique utilizes a rotating shear blade to cut through the coil. It offers excellent precision and can handle a wide range of material thicknesses. Rotary shearing is well-suited for high-volume production and allows for high cutting speeds. 2. Guillotine Shearing: In this method, a straight blade is employed to cut through the coil. It is a versatile technique that can handle different material thicknesses and widths. Guillotine shearing is relatively simple and efficient, making it a popular choice for many applications. 3. Slitting: Slitting involves creating multiple longitudinal cuts in the coil to produce narrower strips. It is commonly used when a coil needs to be divided into smaller coils or when narrower strips are necessary for specific applications. Slitting can be performed using either rotary or straight blades. 4. Laser Cutting: Laser cutting employs a high-powered laser beam to melt or vaporize the material, resulting in a precise and clean cut. It is ideal for cutting complex shapes or patterns and can handle both thin and thick steel coils. Laser cutting offers high accuracy and minimal material distortion. 5. Waterjet Cutting: In this method, a high-pressure stream of water mixed with abrasive particles is used to cut through the coil. It is suitable for a wide range of materials, including steel, and can achieve high accuracy. Waterjet cutting is often utilized for cutting thick coils or when minimizing heat-affected zones is crucial. Each method has its own strengths and limitations, and the selection depends on factors such as material thickness, required precision, production volume, and specific application requirements. Choosing the most suitable method is vital to ensure efficient and high-quality cut-to-length shearing for steel coils.

- Q: I know that steel is generally iron with carbon and probably some other things in it, but I'm doing a research paper on architecture in Tokyo, and touching on the Tokyo Tower.The Tokyo work is larger than the Eiffel Tower by 12 meters, but lighter by 3000 tons. The only reason I can find for the difference in weight is that the Tokyo Tower is made of steel and the Eiffel Tower in made of iron, and since the Tokyo Tower is modeled after the Eiffel, there's really not a substantial difference in the amount of metal used....

- For the same volume of part, like a cubic inch, the weight is very close. If you base the comparison on strength, like a bar strong enough to hold XXX pounds, then the forged bar will be lighter, smaller still hold the weight.

- Q: Why cold rolled stainless steel sheet is lower than cold rolled stainless steel coil?

- Kaiping is the flat coil set into common size. A negative tolerance is the actual thickness of the plate, not the thickness of the mark.

- Q: How are steel coils used in the production of steel brackets?

- Steel coils are used in the production of steel brackets by being fed through a machine that cuts, bends, and shapes the steel into the desired bracket design. The coils provide a continuous supply of raw material, allowing for efficient and high-volume manufacturing of steel brackets.

Send your message to us

Galvanized Steel Sheet in Ciols with Prime Quality and Best Seller

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords