Galvalume Steel Sheet in Coil with Prime Quality and Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Aluzinc Steel Coil Description:

Hot-dip aluzinc steel sheet is substrated on cold rolled steel(CRC) in various strength and specification. Coating composition is 55% aluminium in weight ratio, 43.4% zinc, and 1.5% silicon, with excellent corrosion and heat resistance performance. It is especially useful for countless outdoor and industrial applications.

2.Main Features of the Galvanized Steel Coil:

• Base material for countless outdoor and industrial applications

• Excellent corrosion resistance

• Excellent heat resistance performance

• High strength

• Good formability

• Rust- proof ability

• Good visual effect

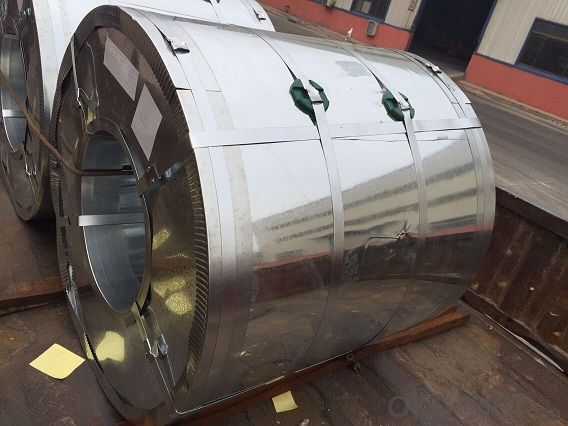

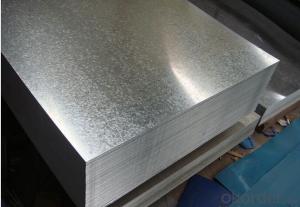

3. Aluzinc Steel Coil Images

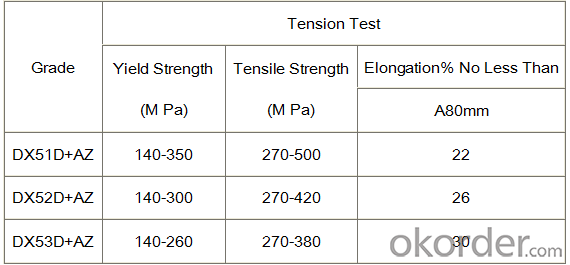

4.Aluzinc Steel Coil Specification

Thickness: 0.3-0.7mm

Width: 914-1250mm

Inner Diameter: 508-610mm

Weight of Steel Coil: 3-15MT

Coating Type: Al-Zn Alloy

Available Dipped Layer: 50-150g/m2

Surface Finish Structure: Normal Spangle & Small Spangle & Zero Spangle

Available Surface Treatment: Passivating & Oiling & AFP & Filming

5.FAQ of Aluzinc Steel Coil

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-30 days, but the shipment will depend on the vessel situation.

- Q: Why does steel with several composites have a greater hardenability from quenching than low carbon steel alloys?Any help would be great

- Bit tricky to explain and I don't know muh about it but steel on its own has lost of gaps in it ( the molecular structure) and when carbon is added thos gaps are filled, I think of it like this: it is easier to punch through expanded polystyrene( with all the little balls) than unexpanded(just a lump of plastic) as the balls are not properly joined and have air pockets between them.

- Q: How are steel coils used in the production of construction machinery?

- Steel coils are used in the production of construction machinery as they are a primary raw material for manufacturing various components such as structural frames, chassis, and other heavy-duty parts. These coils are typically processed and fabricated through cutting, bending, welding, and shaping techniques to create the required components that form the foundation of construction machinery.

- Q: What is the average shelf life of a steel coil?

- The average shelf life of a steel coil can vary depending on various factors such as the type of steel, storage conditions, and maintenance practices. However, on average, a steel coil can have a shelf life of around 6 to 12 months if stored properly in a controlled environment with suitable temperature, humidity, and protection from corrosion. Regular inspection and maintenance can extend the shelf life of a steel coil further.

- Q: and which one is better?i'm looking into buying some aftermarket headers, but companies make them in both chrome and stainless steel

- Chrome is a very hard metal that is plated over regular steel. It often chips and cracks off, allowing rust to form underneath. Stainless steel is an alloy of steel and nickel (I think) - sometimes the pipe is solid stainless, more often it's a coating. It doesn't rust, but also doesn't look as shiny in the beginning (stainless always looks better after a little time 0 chrome plate never lasts.) It's also softer, meaning that it doesn't tend to flake off like chrome does. Chrome plating if mainly for looks - stainless steel is for the longevity of your new parts. Chrome also tends to hold the heat in - not always good, as it will discolour with intense heat (very common on exhaust pipes), and the greater expansion and contraction during its usual heating and cooling cycles tends to make it flake off more easily. Bottom line - are you more interested in performance and keeping the car running well, or are you interested in temporary, short-term looks? After all, there's a reason that pro race engines don't use chrome plating.

- Q: Can steel coils be coated with phosphorescent materials?

- Yes, steel coils can be coated with phosphorescent materials.

- Q: Steel Strings on your guitar or nylons? Why?

- Kind of a silly question. I use steel strings on my steel string guitars and nylon strings on my classical guitar. It's not something you have any choice in; steel string guitars must use steel strings and classical guitar must use nylon strings.

- Q: How do steel coils contribute to sound insulation in buildings?

- Steel coils contribute to sound insulation in buildings by absorbing and dampening sound vibrations. The dense and heavy nature of steel helps to reduce the transmission of sound waves, preventing them from traveling through walls and floors. Additionally, steel coils can be used as a core material in soundproofing panels, enhancing their effectiveness in reducing noise transmission.

- Q: How are steel coils used in the production of fencing materials?

- Steel coils are commonly used in the production of fencing materials as they provide a strong and durable base for manufacturing various types of fences. These coils are typically unrolled and cut into desired lengths, which serve as the main structural component of the fence. Additionally, the steel coils can be further processed to create different fencing designs and features, such as chain link or wrought iron patterns. Overall, steel coils are essential in the production of fencing materials due to their strength, versatility, and ability to withstand harsh environmental conditions.

- Q: How are steel coils used in the manufacturing of construction materials?

- Steel coils are used in the manufacturing of construction materials as they are rolled into sheets or strips, which can then be shaped and formed into various structural components such as beams, columns, and frames. These coils provide the necessary strength and durability required for constructing buildings, bridges, and other infrastructure projects.

- Q: ...particularly for jewelry?

- Surgical stainless steel is a variation of steel usually consisting of an alloy of chromium (12–20%), molybdenum (0.2–3%), and sometimes nickel (8–12%). The chromium gives the metal its scratch-resistance and corrosion resistance. The nickel provides a smooth and polished finish. The molybdenum gives greater hardness, and helps maintaining a cutting edge. In metallurgy, stainless steel (inox) is defined as a ferrous alloy with a minimum of 10% chromium content.[1] The name originates from the fact that stainless steel does not stain, corrode or rust as easily as ordinary steel. This material is also called corrosion resistant steel when it is not detailed exactly to its alloy type and grade, particularly in the aviation industry

Send your message to us

Galvalume Steel Sheet in Coil with Prime Quality and Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords