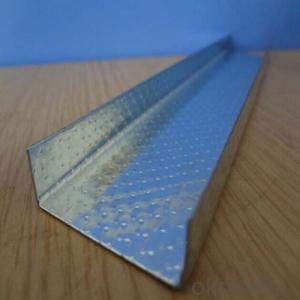

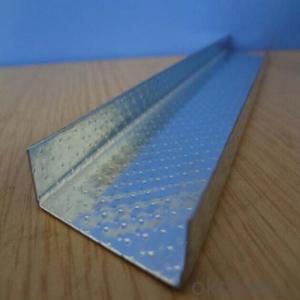

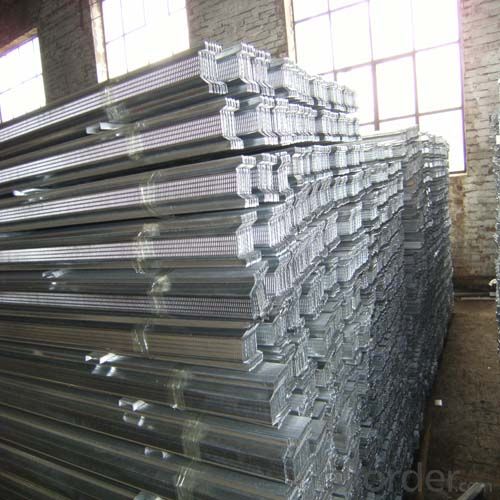

GALVANIZED STEEL PROFILE/ DRYWALL STUD AND TRACK

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 3000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Discription of Galvanized steel profile/drywall stud and track

1>adopting high-grade quality hot-dipped galvanized steel,

2>The products surface zero spangle,and intensity toughness, besides, it can add 20% more than common product.

Specification:

Specification for middle east:

Main Channel | 38x12 mm |

Furring Channel | 68x35x22 mm |

Wall angle | 25x25 mm |

C stud | 50x35 mm |

C Stud | 70x35 mm |

C stud | 75x35 mm |

U track | 52x25 mm |

U track | 72x25 mm |

U track | 75x25 mm |

Specification to Australia:

top cross rail | 25x21x0.75 mm |

25x21x0.75 mm | |

Furring Channel | 28x38x0.55 mm |

16x38x0.55 mm | |

Furring Channel track | 28x20x30x0.55 mm |

16x20x30x0.55 mm | |

Stud | 64x33.5x35.5 mm |

76x33.5x35.5x0.55 mm | |

Stud | 92x33.5x35.5x0.55 mm |

150x33.5x35.5x0.55 mm | |

Track | 51x32x32, 64x32x32x0.55 mm |

76x32x32x0.55 mm | |

Track | 92x32x32x0.55 mm |

Specification to Europe, Russia, UKrain, Georgia. etc

C Stud | 60x27 mm |

U track | 28x27 mm |

C stud | 50x50 mm |

C stud | 75x50 mm |

C stud | 100x50 mm |

U track | 50x40mm |

U track | 75x40 mm |

U track | 100x40 mm |

Product Overviews

Trade Shows

Main Markets: | 15.60% Southeast Asia |

13.2% Eastern Europe | |

12.3% Eastern Asia | |

12.00% North America | |

11.80% Mid East | |

10.8% Africa | |

9.50% South America | |

7.60% Oceania | |

6.70% Western Europe | |

Total Annual Sales Volume: | US$10 Million - US$50 Million |

Export Percentage | 51% - 60% |

FAQ

1. Galvanized Steel Profiles raw material is high quality hot dipped zinc galvanized steel strip, absolute damp proof , heat insulation and high durability , high rust resistance.

2. Hot dipped zinc galvanized steel strip zinc coating is 60-180g/m2.

3.Warm sales in Middle East , Africa , Australia, Malaysia ,and America , which have enjoyed an excellent reputation with high quality and services.

4. The specification can follow up customer requirements.

5. Advanced equipment can make sure exactly size, high quality products.

6.High quality cold rolled continuous hot galvanized plate as raw materials which makes sure it is anti-corrupt and anti-rusty

7.drywall steel profile adopts excellent manufacture equipment,advanced production process, scientific and detecting method. 8. Steel profile has beautiful surface, medium hardness! Good quality *competitive price *large quantity *honesty *good after-service

9.Certificates ISO 9001:2000 Quality management system

- Q: Light steel keel wall to withstand the number of wind load

- This test really no standard, the general wall is not the index of wind pressure, mechanics is also the most test is the impact and static load test, personal feeling according to the thickness of the keel, the height of the wall, supporting the keel, supporting card Whether it is complete, wall pressure against the wind is almost 200 ~ 600Pa no obvious deformation.

- Q: The room to remove the partition, can not retain the original light steel keel gypsum board ceiling?

- The room to remove the partition, you can retain the original light steel keel gypsum board ceiling.

- Q: Light steel keel wall how to calculate

- According to the actual calculation of the amount of work to square meters for the calculation unit, the price of both sides negotiated or set quotas. According to how you talk about the calculation, if not talk, the market is calculated by single-sided!

- Q: Light steel keel wall in the end is how much money to know

- Such a small area. But also deduction doors and windows. It is estimated that many people are willing to do. Beijing's labor costs are also high. Generally cut off about 75 square meters.

- Q: Gypsum board partition wall how to sound insulation

- Single-walled wall due to the law of quality constraints, must be a heavy wall in order to obtain good sound insulation performance. For the office partition wall, in order to meet the national minimum standard rw = 40db requirements of single-layer partition at least 100kgm2 above the surface density (surface density is the weight per square meter of the wall). If the wall is divided into two or more layers, the sound insulation will be significantly improved.

- Q: Home improvement in the partition

- Light body board partition: first that light body wall panels, refers to JG / T169-2005 "building partition with light strip" for the building within the wall of the wall prefabricated panels, partitions The board includes glass fiber reinforced concrete slab, glass fiber reinforced gypsum hollow slab, steel wire (steel mesh) reinforced concrete slab, light concrete slab, composite sandwich light strip and so on.

- Q: Gypsum board wall above the good paint glass?

- Not good equipment, the main fear is not bearing, long-term bearing gypsum board may not stand Gypsum board wall is made of light steel keel plus gypsum board made of its light weight, small footprint, easy to disassemble.

- Q: Light steel keel with what screws fixed gypsum board

- With fast wire. Fast wire: cone tip, countersunk head, cross marks, double wire with boiled or galvanized surface treatment. ?????? Fast wire that is fast teeth screws, usually usually belong to self-attack class.

- Q: I would like to have a toilet in the house, bathroom with mineral wool board cut off or light steel keel gypsum board line?

- These two estimates are problematic, you can use light steel keel cement pressure plate nail steel wire mesh paint, do waterproof post-paste wall tiles, the following also do waterstops

- Q: How much does it cost to use a light steel keel gypsum board?

- 800 yuan to 1,000 yuan, which is the cost of the price If it is the company to do you probably about 1800-2,200 yuan.

Send your message to us

GALVANIZED STEEL PROFILE/ DRYWALL STUD AND TRACK

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 3000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords