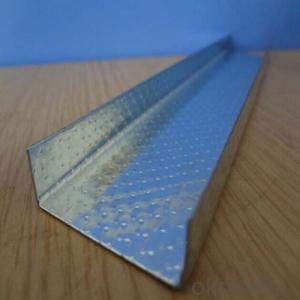

Drywall Profile Galvanized Steel STUD and TRACK

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification & Introduction

Galvanized Drywall Track and Studs Light Steel Keel Furring

DESCRIPTION | Size(mm) | Length(mm) |

25mm Top Cross Rail | 25*21*0.55 | 2900/3000/3600/4800/6000 |

25mm Top Cross Rail | 25*21*0.75 | 2900/3000 3600/4800/6000 |

16mm Furring Channel Track | 16*20*30*0.55 | 3000 |

28mm Furring Channel Track | 28*20*30*0.55 | 3000 |

16mm Ceiling Batten | 36*16*0.5 | 2900/3000 4800/6000 |

22mm Cyclonic Ceiling Batten | 35*22*68*0.55 | 2900/3000 4800/6000 |

40mm Ceiling Batten | 35*40*70*0.55 | 4800/6000 |

16mm Furring Channel | 16*38*0.55 | 3000/3600/4800/6000 |

28mm Furring Channel | 28*38*0.55 | 3000/3600/4800/6000 |

51mm Stud | 51*33.5*35.5*0.55/0.75 | 2400/2700/3000/3600/4200/4800/6000 |

64mm Stud | 64*33.5*35.5*0.55/0.75/1.15 | 2400/2700/3000/3600/4200/4800/6000 |

76mm Stud | 76*33.5*35.5*0.55/0.75/1.15 | 2400/2700/3000/3600/4200/4800/6000 |

92mm Stud | 92*33.5*35.5*0.55/0.75/1.15 | 2400/2700/3000/3600/4200/4800/6000 |

150mm Stud | 150*33.5*35.5*0.75/1.15 | 3600/4800/6000/7200 |

51mm Track | 51 * 32/50 * 0.55/0.75 | 3000 |

64mm Track | 64 * 32/50 * 0.55/0.75/1.15 | 3000 |

76mm Track | 76 * 32/50 * 0.55/0.75/1.15 | 3000 |

92mm Track | 92 * 32/50 * 0.55/0.75/1.15 | 3000 |

150mm Track | 150 * 32/50 * 0.75/1.15 | 3000 |

Leg Stopping Angle 6mm | 30*6*0.4 | 3000 |

Leg Stopping Angle 10mm | 30*10*0.4 | 3000 |

Leg Stopping Angle 13mm | 30*13*0.4 | 3000 |

Leg Stopping Angle 16mm | 30*16*0.4 | 3000 |

External Angle 90 | 30*30*0.4 | 2400/2700/3000/3600 |

Shadowline stopping angle | 10*10*30*0.4 | 3000 |

DESCRIPTION | Thicknes |

Adjustable Direct Fix | 1.5mm |

Beta Fix | 1.5mm |

Long Beta Fix | 1.5mm |

Side mounted TCR Suspension Clip | 0.8mm |

Locking Key | 0.7mm |

TCR Suspension Clip | 0.8mm |

5mm Rod Suspension | 5mm |

Direct Fix Clip -150 long | 1.0mm |

Direct Fix Clip-92 | 1.0mm |

Right Angle Rod Bracket | 1.2mm |

R0d Brackets | 1.2mm |

Ceiling Bracket | 1.6mm |

Floor Pin | |

Direct Fixing Clips—Screw Fix | 1.2mm |

Direct Fixing Clips-Concrete | 1.2mm |

Direct Fixing Clips 175mm | 1.0mm |

Direct Fixing Clips 75mm | 1.0mm |

Slotted Web Cleat | 3mm |

Advantages of Galvanized Drywall Track and Studs :

1. Our products’ raw material is high quality hot dipped zinc galvanized steel strip, absolute fireproof and heat insulation, waterproof and antirust, anticorrosive , high durability

2.Hot dipped zinc galvanized stee strip zinc coating is 80-275gsm.

3. Double sized galvanization volume make sure that the plaster bone is corrupt and rust resistance.

4. Warm sales in Middle East , Africa , Australia, Malaysia ,and America , which have enjoyed an excellent reputation with high quality and services.

5.Manufacture the special specification products for customers

6. High quality raw material guarantees the light steel keel of life and good performance of construction.

7. Possese own ten precision cold rolled steel strip production line.

Certificates

ISO 9001:2000 Quality management system.

Product Show

FAQ

1.Sample: small sample can be offered by free

2.OEM: OEM is accepted

3.MOQ: small order is ok

4.Test: any third party is accepted to test

5.Factory: Can visit factory any time

6.Delivery Time: small order is within 7days or according to your order

- Q: 75 series of light steel keel wall double-sided double-layer 12 thick plaster board filled with sound insulation noise can reach the number of decibels

- Light steel keel gypsum board system is usually double-sided wall structure, that is, "plate - keel (cavity) - plate" structure, each side of the wall board for the single or double gypsum board, Light steel keel. In order to obtain better sound insulation effect, in the cavity filled with rock wool board or glass wool.

- Q: Home to decorate the ceiling, playing the wall, I learned from the market can be resistant, dragon card, Saint Gobanchenko these brands of light steel keel gypsum board which good point?

- You said these are very good brand, Saint-Gobain and Long card companies with more. The material is on the one hand, the ceiling is the most important woodworking craft and craftsmanship. Material is not a problem

- Q: Lightweight wallboard light steel keel how to construction

- Damp room and steel plate plaster wall, light partition board keel spacing should not be greater than hundreds of millimeters, the installation of supporting keel, the support card should be installed in the direction of the vertical keel opening, partition wall card should be four hundred To six hundred millimeters, from the keel at both ends of the distance should be twenty to twenty five millimeters, should be fixed according to the location of the ball along the edge, along the keel and border keel, keel line should be coincident with the line.

- Q: Is it possible to use a hollow brick or a 95 brick?

- With hollow bricks, because it is relatively light, will not cause the floor cracking. In fact, there are many other wall materials, including light steel keel gypsum board, steel mesh, etc., both light, but also save the space as usual when you decorate the brick wall should be used 1/2 brick wall, if the hollow brick Do, the wall width of the brush with 120 thick, the main advantage is the weight of light is generally 95 brick wall 2/3, will not bring too much burden on the structure of the house itself, noise effects can be, because the hollow brick inside Hole in the arrangements on the noise function to consider, relatively speaking, 95 brick wall thickness and hollow brick is the same, heavy weight, sound insulation effect than the hollow brick to slightly better. But I suggest that the main building brick wall, then the best use of steam concrete blocks, to achieve the best results!

- Q: House decoration, the designer said the wall with light steel keel good, but the construction told me that this low efficiency can only be maintained for 4,5 years so I do not know in the end listen to who

- With light brick wall, there are 1.5 and 1.2 the price is about 60 it

- Q: Light steel keel + gypsum board wall and other wall joints how to strengthen?

- Are generally used to deal with the patch to prevent the brush at the brushing of latex paint, keel and wall connection more than a few nail fixed

- Q: Light steel keel gypsum board wall panels have cracks how to do?

- Many reasons caused by the pre-construction time may be the quality of gypsum board is not very good, and there is no wrong between the gypsum board, give you the proposal is to remove all the four sides of the seam, new plaster bandage, putty powder from the new Scrape, otherwise the other method is only a temporary solution,

- Q: Light steel keel wall Why do not cross brace welding with welding

- Then the book is too much trouble to weld, to master the master to welding, Moreover, the time is too long, so no one with the welding.

- Q: Has installed a wooden floor, you can do in the above light steel keel wall?

- Can, to the dragon it to use a little bit of the screw, but look at your floor is still in the cement or above the floor to do in the cement above with a drill to pull the explosion can be a With a long screw, If it is done on the floor of the board it, It is recommended to use a little bit of the screw to play on the above plus gasket To do about the foot line, and the floor color, only to coordinate points

- Q: How to construct double - sided double gypsum board partition wall

- Line: according to the design and construction plans, in accordance with the keel width of the elastic line, has been done on the ground or ridge to release the wall position line, door and window openings border line, and put the top, wall keel position edge. To cover the panel of the long, wide sub-file, to ensure that the keel position is correct. Heaven and earth keel installation, along the ball line fixed top, to keel, fixed point spacing should not be greater than 600mm, keel docking should remain straight. Fixed keel keel, keel the end should be fixed, fixed should be solid. Wall, column edge keel with nails or wood screws and walls, column fixed, nail distance of 1000mm.

Send your message to us

Drywall Profile Galvanized Steel STUD and TRACK

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords