Galvanized Steel Cuplock Scaffolding System with Good Anti-rust for Large Construction CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details of Galvanized Steel Cuplock Scaffolding System with Good Anti-rust for Large Construction

Name Cuplock Scaffold System Size Many sizes or as your request Main Material Q235/345 Steel Surface Treatment High Protected Painted, Powder Coating, Electric Gavenized, Hot Dip Gavenized. Color Silver, Orange, Red Certificate SGS, EN12810. Service OEM Service available MOQ 50T Payment T/T, Western Union Delivery Time 15-25 days after deposite Packing in bulk or steel pallet or as your request production capability 50 tons per day Main Market Africa, South America, the Middle East and Asia

Descriptions of Galvanized Steel Cuplock Scaffolding System with Good Anti-rust for Large Construction

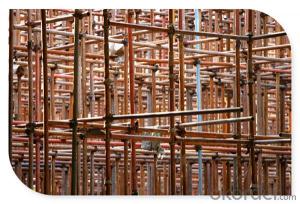

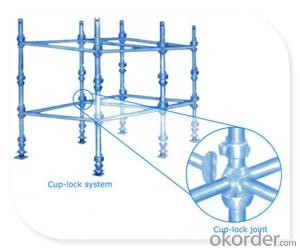

1.Cuplock scaffolding system is a type of scaffolding characterized by a joining method that uses metal cups to lock beams together.

2.Like other types of scaffolding, cuplock scaffolding system is a temporary network of frames used to support workers during construction or renovation of a structure, such as a building, where high access points are needed.

3.The overall stability and ease of assembly of the cuplock scaffolding system makes it the preferred type for projects where a large scaffolding must be constructed quickly and must support a relatively heavy load.

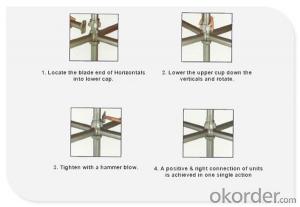

4.The distinctive cuplock scaffolding joint system consists of three basic components: a top cup, a bottom cup, and ledgers. The cup components are ringlike, each with a hollow center that allows the round verticle bar to pass through it.

5.We have been catering to wide requirements of our clients in the construction industry by manufacturing a wide range of cuplock scaffolding. Fabricated as per the specifications of our clients these are acclaimed for high durability and wear resistance.

The Measures of Galvanized Steel Cuplock Scaffolding System with Good Anti-rust for Large Construction

Length(mm) Thickness(mm) Diameter(mm) Weight(kg) Scaffolding Standard 3000 3.2 48 15 2400 3.2 48 12 1800 3.2 48 9 1200 3.2 48 6 600 3.2 48 3 Scaffolding Ledger 1800 3.2 48 6.9 1500 3.2 48 5.9 1200 3.2 48 4.8 900 3.2 48 3.7 600 3.2 48 2.7 FAQ

1. What is considerations of Scaffolding installation?

There must be a fire protection measures and specialist care, safety personnel patrol inspection when electricity, gas welding work on the scaffold,

(1) scaffold frontage hurtful to prevent falling objects protection is required.

(2) During take down the scaffolding, fencing and warning signs should be set up on the ground, prohibit others person besides the operator

2.What are the certifications of your products?

Certified by SGS, BS1139, EN74, Local Test Report.

3. How long is the warranty period for your product?

Our products warranty is 2 years.

- Q: Erection of scaffolding accessories

- Erection of scaffolding accessories:Door frame should be installed from one end to the other end of the extension, and layer by layer to change the direction of the set, not the opposite. After the completion of one step, should check and adjust its level and verticality. Scaffolding should be built around the building, continuous, synchronous erection elevation, in the form of a closed structure around the building; if not closed, the scaffold should be added at both ends of the wall.

- Q: I plan on playing tennis and doing track and field at school... Im getting the piercing this month and it won't be healed in time to take it out. How can I conceal it or possibly even help it heal faster??

- Well an industrial piercing isn't exactly going to get in your way, just put your hair up in a pony tail so your hair doesn't get snagged on it. I wouldn't suggest trying to cover it with anything though, you'll be putting the piercing at risk of infection from trapping bacteria, especially if you're going to end up sweating.

- Q: i already found the force in rope 2 but im not getting the force in rope 1.

- The tension in the two vertical ropes must sum to 700N in order to balance the window washer. EDIT. In order to find the answer for each rope, I need to know how long the scaffold is and where the window washer is standing. EDIT. Taking moments about the end nearest to window washer. T1*3.044 = 298.6*1.522 + 700*1.51 ----> T1 = 496.54 N (2. d. p.) Taking moments about the other end. T2*3.044 = 298.6*1.522 + 700*1.534 ----> T2 = 502.06 N (2. d. p.) T1 + T2 = 496.54 + 502.06 = 998.6 = 700 + 298.6 as required.

- Q: A scaffold is constructed by placing two supports under a 13 ft, 9 in (a) board weighing 84 lbs. The supports are each 2 ft, 8 in (b) from their respective ends. Two painters stand on the board; one weighs 158 lbs and stands 4 ft, 11 in (c) from the left end of the board. Where must the 222 lbs painter stand so that each support carries the same weight? (express your distance in feet from the right end of the board (d).)please help!! thanks(:

- Total weight = 222 + 158 + 84 = 464 lb So, each support must carry 232 lbs Working in inches: Take moment about Right hand end Board is assumed to be uniform - CG is at the center (232 x 32) + (232 x 133) = (158 x 106) + ( 84 x 82.5 ) +(222 x d)7424 + 30856 = 16748 + 6930 + 222d 222d = 14602 d = 65.77 inches Distance of 222 lb painter should be 5ft 5.77inches from Right end

- Q: I sincerely ask you to help me, door scaffolding, build 30 meters high, without any reinforcement points of the construction program. Thanks, high marks!

- 1 in order to design and construct the steel pipe scaffold in the door, to carry out the relevant regulations of the state on safe production, and to realize the advanced technology, reasonable economy and safe application.

- Q: Scaffold Piercing Aftercare?Ok, so I was looking into getting an industrial piercing. However, I am very very serious about the aftercare, and I would dread any infection or anything going wrong. So, I was wondering, what are some aftercare cleaning tecniques/methods? I already know that antibacterial soap is good, as is the H20 cleaning spray stuff. And that you are supposed to clean it twice a day. But how and when should I do this? I have school which I can clean it before I go in the morning, but I don't get back until four, and then I take a shower at night always. I know it sounds silly, but are there some tips you have? Thanks!

- I've had my industrial for over two years, it's a great piercing but aftercare is important and it does take awhile for it to heal. Here was my schedule for my industrial and all of my piercings since then... When I got my industrial I was in school until about 4 pm as well (I'm no longer in school now so I do it a little differently now) so this schedule might be doable for you. I took showers in the morning but that's not a huge problem. I'd wake up in the morning and while showering I'd clean my piercing with antibacterial soap AFTER I washed my hair and did my other shower rituals. Then when I got out of the shower I would do a short sea salt soaks (sea salt soaks are going to be much better for your piercing than H2O). I'd mix non-iodized sea salt in a clean new dixie cup with warm water, then I'd bend over and let my ear soak in the water for about five minutes. Sea salt soaks are great because they help promote healing and prevent/clean up infections. Then I'd go to school and after school I'd do a simple little rinse with a saline solution (which you can buy at any grocery store, usually around the contact supplies). Saline is good for when you're in a rush and don't have time to do a sea salt soak. Then at night I'd do a long sea salt soak and I'd soak my ear for about 10-15 minutes. Now for you, since you shower at night I would clean my ear with antibacterial soap every night in the shower and do a long sea salt soak after my shower, before bed. Then in the morning I'd so a short little sea salt soak before school and after school you can use a saline solution or the H2O. Good luck! This worked for me with all 6 of my piercings.

- Q: Can anyone give a very brief description on all three scaffold scenes in The Scarlet Letter?

- concentration your interest on who's on the scaffold, how they react to the regularly occurring public shaming, and what the reader learns with regard to the character from examining the define of them on the scaffold.

- Q: hi, i already have my cartlidge pierced on my right ear and thinking about getting a scaffold piercing on my left ear. will a scaffold piercing hurt more than my cartlidge piercing,,less,,or about the same???thanks answers apprecietedhope =] xx

- Several people have told me it hurts about the same. I do not have one, sorry couldn't be more help than that.

- Q: I have some scaffolding that I would like to use to build a temporary slide to my swimming pool. The slide I would like to be made out of the side parts which are the ones like rectangles with bars going across them and I have a variety of poles. I would then like to put a slippery tarpaulin on to the frame.But how would I hold the tarpaulin up, because the metal poles will be too short? So that if someone slid down it they would not just burst through the tarpaulin and hit the floor after hitting around five metal poles!

- Why would you even consider something like that? Obviously you kids and your family use this pool, why put them at risk making a temporary slide with scaffolding. Not a good idea.

- Q: Disc scaffolding and bowl buckle scaffolding which kind of bridge support better?

- Characteristic1 Multi function. According to the specific requirements of construction, can be composed of multiple 0.6m module group frame size and load of single row, double row scaffolding, supporting frame, supporting the construction of equipment to enhance the function of frame columns, and other materials, and can do curve layout. Scaffolding can be adjusted with the bottom of the support, adjustable upper support, dual adjustable early demolition, pick beam, pick up the rack and other accessories with the use of various types of steel scaffolding can be used in conjunction with each other to achieve a variety of multi-functional

Send your message to us

Galvanized Steel Cuplock Scaffolding System with Good Anti-rust for Large Construction CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords